Single-component polyurea modified polyurethane waterproof coating and a preparing method thereof

A polyurethane waterproof, one-component technology, applied in the field of polyurethane waterproof coatings, can solve problems such as foaming and low viscosity, and achieve the effect of solving low viscosity, low ketone taste, and good construction experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

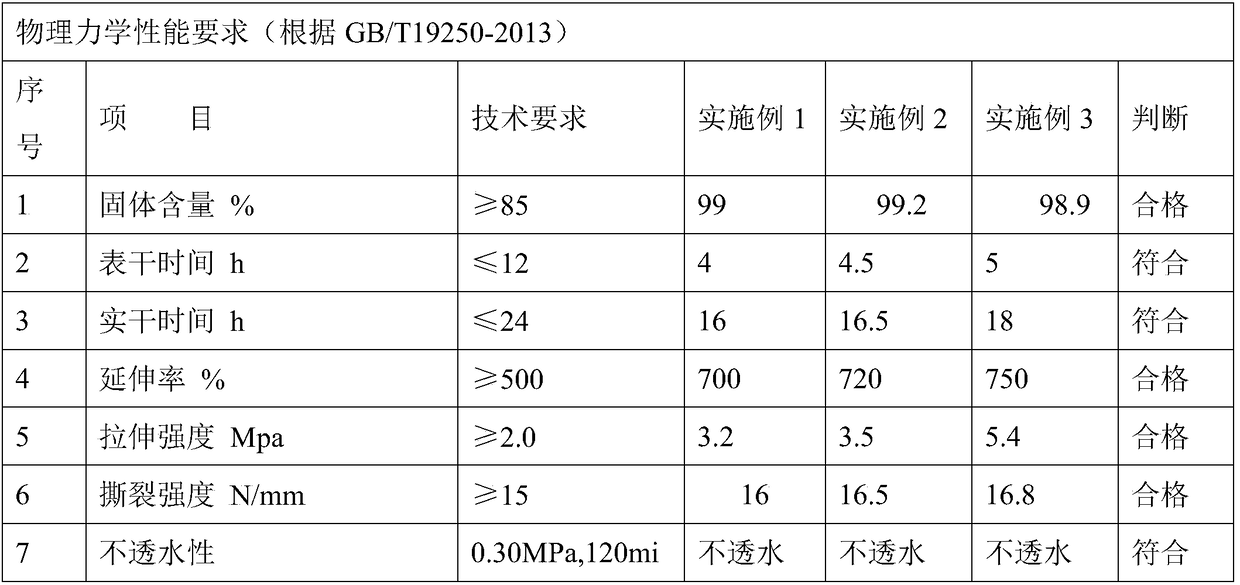

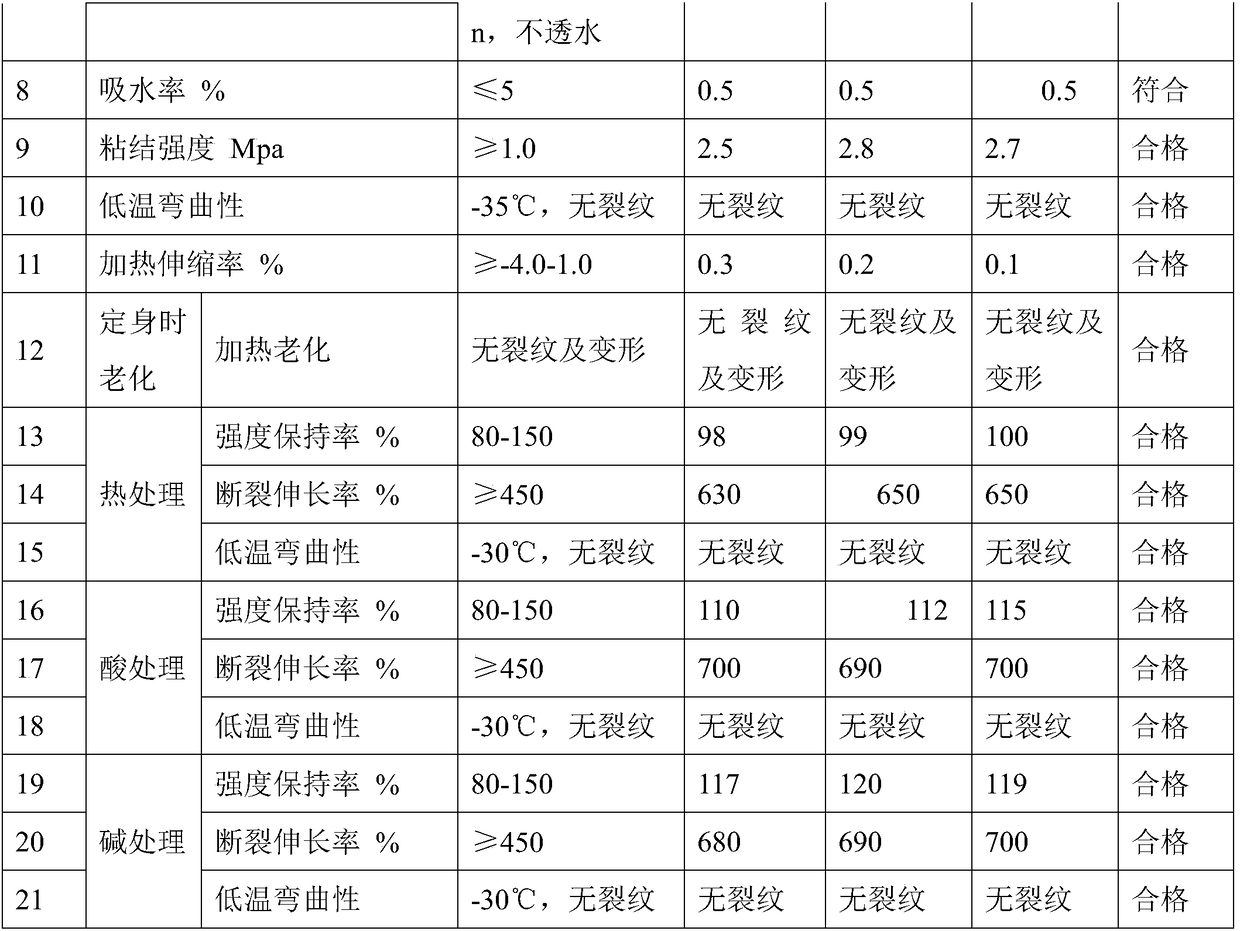

Examples

Embodiment 1

[0032] A one-component polyurea modified polyurethane waterproof coating, comprising the following components in parts by weight: 18 parts of polyether diol 2000D, 5 parts of polyether diol 1000D, 10 parts of polyether triol 6000D, chlorine 25 parts of paraffin wax, 32 parts of talc, 2 parts of titanium dioxide, 0.1 part of 1,4-butanediol, 7.6 parts of diphenylmethane diisocyanate, 2 parts of self-made latent curing agent, 0.1 part of dibutyltin dilaurate.

[0033] The preparation method of the above-mentioned self-made latent curing agent is: calculated according to the total mass fraction of 100%, it is composed of the following substances: 65% of 3-penten-2-one, 35% of 2-methylpentamethylenediamine; it is prepared by the following method: Under the protection of nitrogen, add the measured 3-penten-2-one into the closed dispersion tank, add the measured 2-methylpentamethylenediamine dropwise under stirring, and control the temperature below 40°C for 30 minutes; then raise the...

Embodiment 2

[0040] A one-component polyurea-modified polyurethane waterproof coating, comprising the following components in parts by weight: 22 parts of PPC2000D, 28 parts of trioctyl citrate, 34 parts of talcum powder, 2 parts of titanium dioxide, and 0.3 parts of trimethylolpropane 5.6 parts of hexamethylene diisocyanate, 3.5 parts of self-made latent curing agent, and 0.2 parts of stannous octoate.

[0041] The preparation method of the above-mentioned self-made latent curing agent is: calculated according to the total mass fraction of 100%, it is composed of the following substances: 69% of 3-hydroxy-2-butanone, 31% of p-phenylenediamine; it is prepared according to the following method: in the presence of nitrogen protection Add the measured 3-hydroxy-2-butanone into the closed dispersion tank, add the measured p-phenylenediamine dropwise under stirring, control the temperature below 40°C for 30 minutes; then raise the temperature to 120°C and reflux to separate the water ; When the...

Embodiment 3

[0048] A one-component polyurea modified polyurethane waterproof coating, comprising the following components in parts by weight: 26 parts of PTMEG2000, 20 parts of trioctyl phosphate, 42 parts of talcum powder, 2 parts of titanium dioxide, 1,6-hexanediol 0.5 parts, 2 parts of 4,4'-dicyclohexylmethane diisocyanate, 3 parts of self-made latent curing agent, 0.1 part of lead isooctanoate.

[0049] The preparation method of the above-mentioned self-made latent curing agent is: calculated according to the total mass fraction of 100%, it is composed of the following substances: 75% of methyl nonyl ketone, 25% of diethyltoluenediamine; it is prepared according to the following method: under the protection of nitrogen , add the measured methyl nonyl ketone into the closed dispersion tank, add the measured diethyltoluenediamine dropwise under stirring, control the temperature below 40°C and react for 30 minutes; then raise the temperature to 120°C and reflux to separate the water; Com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com