Water-based printing ink with strong shallow screen transferability, and preparation method thereof

A printing ink and transfer technology, which is applied in the field of water-based printing ink and its preparation, can solve the problems that water-based printing ink cannot meet the needs of consumers, and achieve the effects of improving the transfer performance of shallow nets, uniform coloring, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

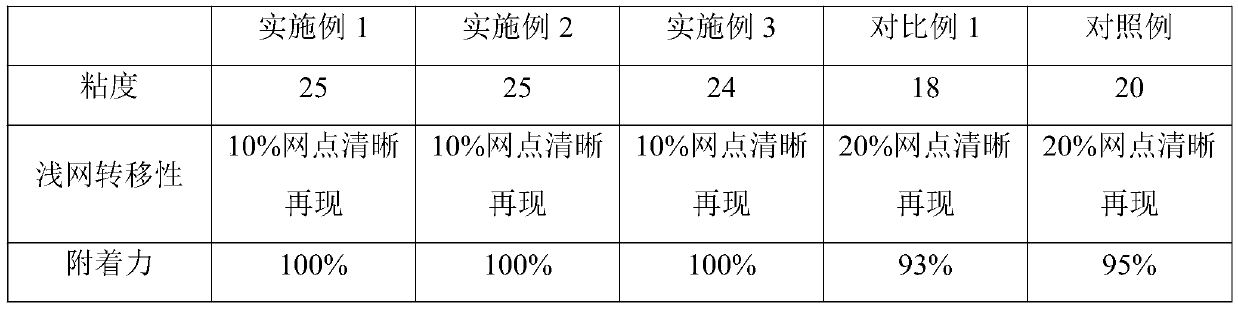

Examples

preparation example Construction

[0049] The present application also provides a preparation method for the above-mentioned water-based printing ink with strong shallow net transferability, comprising the following steps:

[0050] (1) Add water-based polyurethane resin and modified acrylic resin to the mixer, and stir at a rate of 400-600 rpm at a temperature of 50-60°C for 30-50 minutes to obtain a premix;

[0051] (2) Put the water-based wax slurry and inorganic pigment into the mixer for mixing and stirring. The stirring temperature is 35-40°C and the stirring rate is 500-600 rpm. After stirring for 20-30 minutes, the mixed slurry is ground by a three-roller machine , and grind to a particle size of less than 10 μm to obtain a mixed color paste;

[0052](3) Put the pre-mixture obtained in step (1) and the mixed color paste obtained in step (2) into the reactor together, and then add leveling agent and defoamer to the reactor at a speed of 1000 to 1200 rpm Stir at a high speed for 60-80 minutes to obtain ro...

Embodiment 1

[0058] Preparation of modified acrylic resin: In a reactor, mix dimethylaminoethyl methacrylate, methyl acrylate, and styrene in a molar ratio of 6:3:1, heat the reactor, and wait until the temperature reaches 65°C Insulate and stir for 35 minutes, then raise the temperature to 85°C, add an appropriate amount of initiator, continue to insulate and stir at this temperature for 55 minutes, adjust the pH value of the solution to 7.5 after the heat preservation is completed, then filter and dry to obtain a modified acrylic resin.

[0059] Prepare raw materials according to the following weight percentages:

[0060] Water-based polyurethane resin 30%

[0061] Modified acrylic resin 15%

[0062] Water-based wax paste 3%

[0063] Inorganic pigment 2.5%

[0064] Leveling agent 0.5%

[0065] Defoamer 0.5%

[0066] Deionized water balance;

[0067] Preparation of water-based printing ink with strong shallow web transfer:

[0068] (1) Add water-based polyurethane resin and modifie...

Embodiment 2

[0073] Preparation of modified acrylic resin: In a reactor, mix dimethylaminoethyl methacrylate, methyl acrylate, and styrene in a molar ratio of 6:3:1, heat the reactor until the temperature reaches 67.5°C Insulate and stir for 40 minutes, then raise the temperature to 86.5°C, add an appropriate amount of initiator, continue to insulate and stir at this temperature for 60 minutes, adjust the pH value of the solution to 8.0 after the heat preservation is completed, then filter and dry to obtain a modified acrylic resin.

[0074] Prepare raw materials according to the following weight percentages:

[0075] Water-based polyurethane resin 40%

[0076] Modified acrylic resin 20%

[0077] Water-based wax paste 4%

[0078] Inorganic pigment 3.5%

[0079] Leveling agent 1%

[0080] Defoamer 1%

[0081] Deionized water balance;

[0082] Preparation of water-based printing ink with strong shallow web transfer:

[0083] (1) Add water-based polyurethane resin and modified acrylic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com