High-efficiency ceramic body reinforcing agent composition and product prepared thereby

The technology of a ceramic body and a reinforcing agent is applied to the high-efficiency ceramic body reinforcing agent composition and the products prepared therefrom, and the field of the ceramic body reinforcing agent can solve the problems of high price and the like, and achieve the effect of reducing the cracking rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

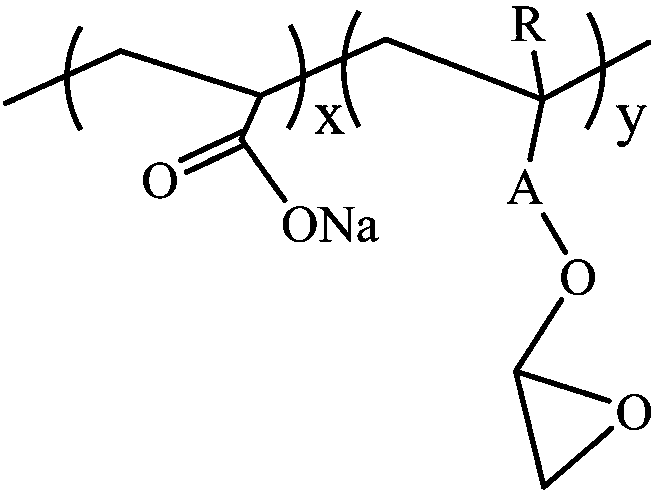

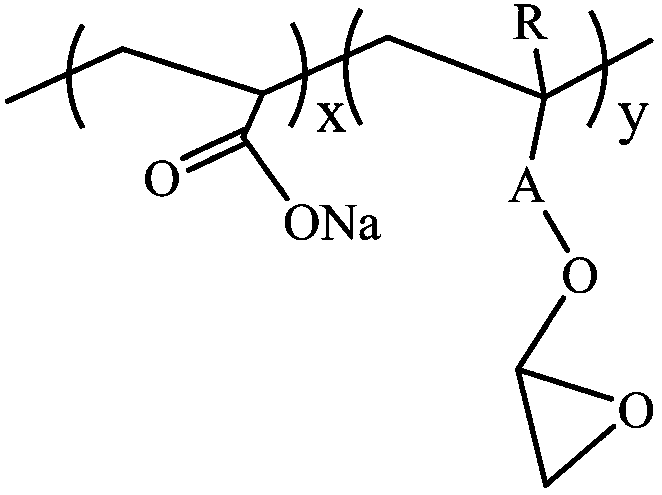

[0020] A high-efficiency ceramic body reinforcing agent composition, which consists of: 5% acrylic pressure-sensitive adhesive emulsion (pH 8-9, 44% by mass), 3% sodium alginate, 8% epoxy modified Sodium polyacrylate X, the rest is water.

[0021] Wherein, the epoxy-modified sodium polyacrylate X is prepared by aqueous solution radical polymerization, and the preparation method comprises the following steps: 10 parts of allyl glycidyl ether, 0.3 parts of sodium dodecylbenzenesulfonate , 2 parts of thioglycolic acid, 1 part of thioglycollate, 80 parts of water were added to the reactor, fully dispersed evenly, and then 30 parts of sodium acrylate were added thereto, and the system was heated to 60°C; then hydrogen peroxide was added dropwise into the reactor, After 0.8h of dropwise addition, keep the reaction for 4 hours, then cool to room temperature, and discharge to obtain epoxy-modified sodium polyacrylate X.

[0022] Measure the reinforcing performance of the green body r...

Embodiment 2

[0024] A high-efficiency ceramic body reinforcing agent composition, which consists of: 4% acrylic pressure-sensitive adhesive emulsion (pH 9-10, 50% by mass), 1% carboxymethyl starch, 15% epoxy Modified sodium polyacrylate Y, the rest is water.

[0025] Wherein, the epoxy-modified sodium polyacrylate Y is prepared by aqueous solution radical polymerization, and the preparation method comprises the following steps: mixing 5 parts of glycidyl methacrylate, 0.03 part of styrene-ethylphenol polyoxyethylene ether , 0.02 parts of sodium laurate, 2 parts of sodium bisulfite, and 60 parts of water are added to the reactor, fully dispersed, and then 20 parts of sodium acrylate are added to it, and the system is heated to 80°C; then persulfuric acid is added dropwise into the reactor Potassium was added dropwise in 1 hour. After 2 hours of heat preservation reaction, it was cooled to room temperature, and the epoxy-modified sodium polyacrylate Y was obtained after discharge.

[0026] ...

Embodiment 3

[0028] A high-efficiency ceramic green body reinforcing agent composition, which consists of: 8% acrylic pressure-sensitive adhesive emulsion (pH 7-8, 54% by mass), 1.4% water-soluble starch, 12% epoxy modified Sodium polyacrylate Z, the rest is water.

[0029] Wherein, the epoxy-modified sodium polyacrylate Z is prepared by an aqueous solution radical polymerization method, and the preparation method comprises the following steps: mixing 7 parts of glycidyl ether acrylate, 0.2 parts of didodecylphenyl ether disulfonate Sodium acrylate, 1.5 parts of sodium phosphite, 1.0 part of sodium phosphite, 68 parts of water were added to the reactor, fully dispersed, and then 24 parts of sodium acrylate were added to it, and the system was heated to 70°C; then added dropwise to the reactor Ammonium persulfate was added dropwise in 0.6 hours. After 2-5 hours of heat preservation reaction, it was cooled to room temperature and discharged to obtain epoxy-modified sodium polyacrylate Z.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com