Clamping type manipulator

A manipulator and gripping technology, which is applied in the direction of manipulators, conveyor objects, manufacturing tools, etc., can solve the problems of manipulator and frame dust particle pollution, failure to meet the requirements of handling time, handling speed and long time, etc., to prevent dust Particle contamination, shorter transit time, and metal contamination prevention effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

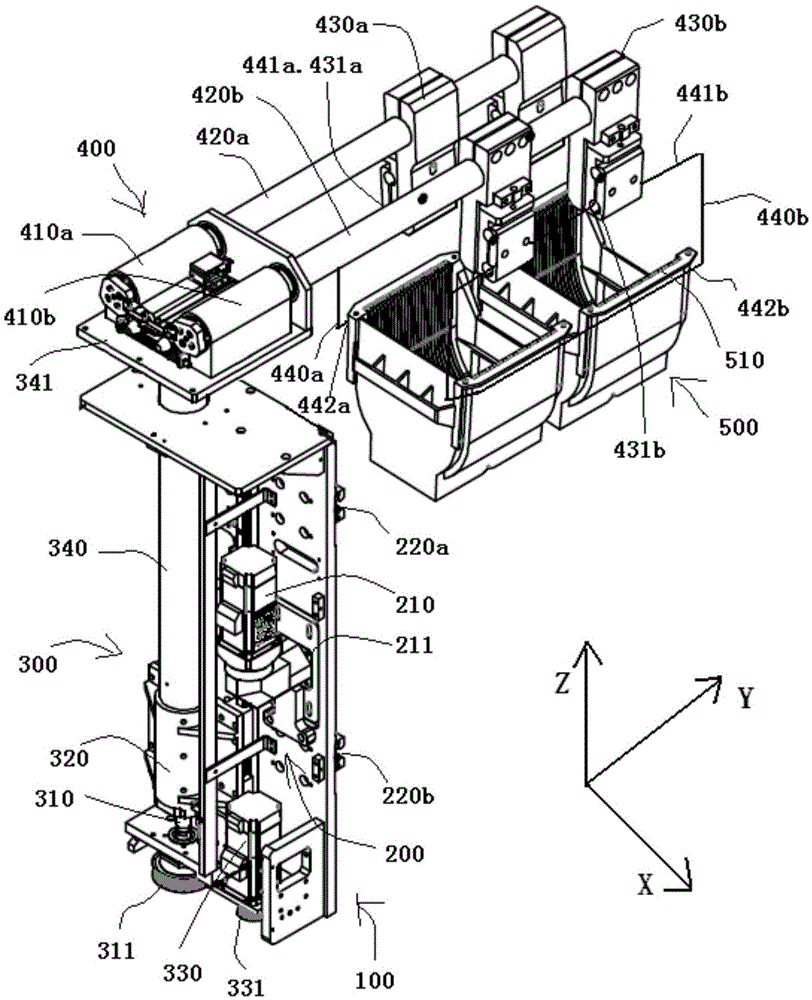

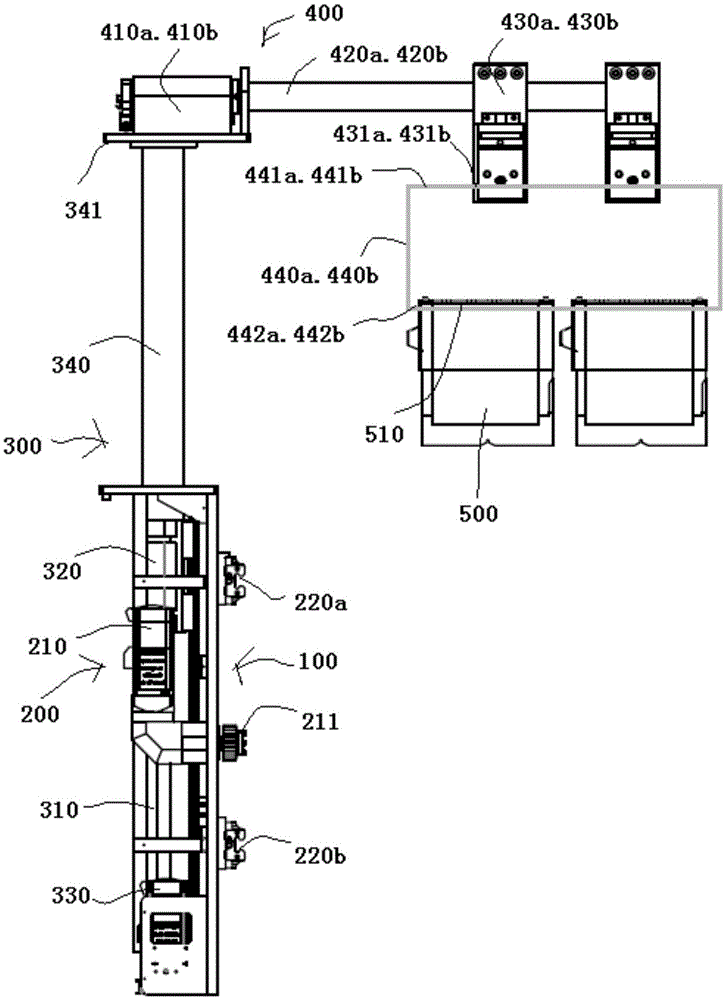

[0024] see figure 1 and figure 2 The gripping manipulator shown includes a machine base 100, which is a vertical machine base.

[0025] The side of the machine base 100 is provided with an organic base side shift driving mechanism 200. The function of the machine base side shift driving mechanism 200 is to drive the machine base 100 to move sideways. The machine base side shift driving mechanism 200 in this embodiment includes a pair of The horizontal slide rails 220a, 220b on the side of the support 100 and the side shift motor 210 fixed on the support 100, the rotation output end 211 of the side shift motor 210 extends outwards, and is connected with the fixed rack (not shown in the figure) Engaging, when the lateral movement motor 210 works, the machine base 100 can be moved ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com