Full-automatic liquor steaming equipment based on feeding upon steam

A wine steaming equipment, fully automatic technology, applied in the preparation of alcoholic beverages, etc., can solve the problems of uneven feeding, unguaranteed quality, slow speed, etc., and achieve the effect of uniform feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

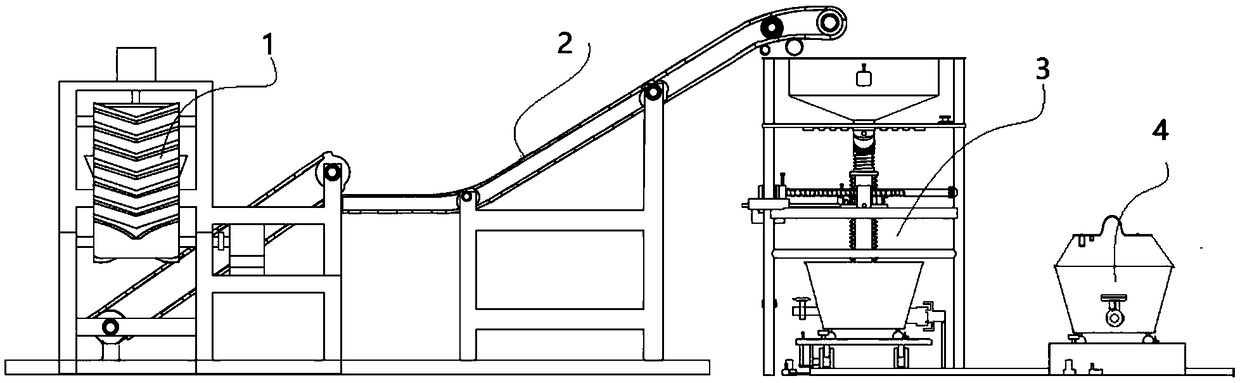

[0063] The present invention provides a fully automatic steaming equipment for steaming wine, its overall structure diagram is as follows figure 1 shown.

[0064] The fully automatic wine steaming equipment includes a V-shaped automatic mixing device 1 , a wine steaming raw material conveyor belt 2 , a steam feeding wine steaming device 3 and an orbital steamer device 4 .

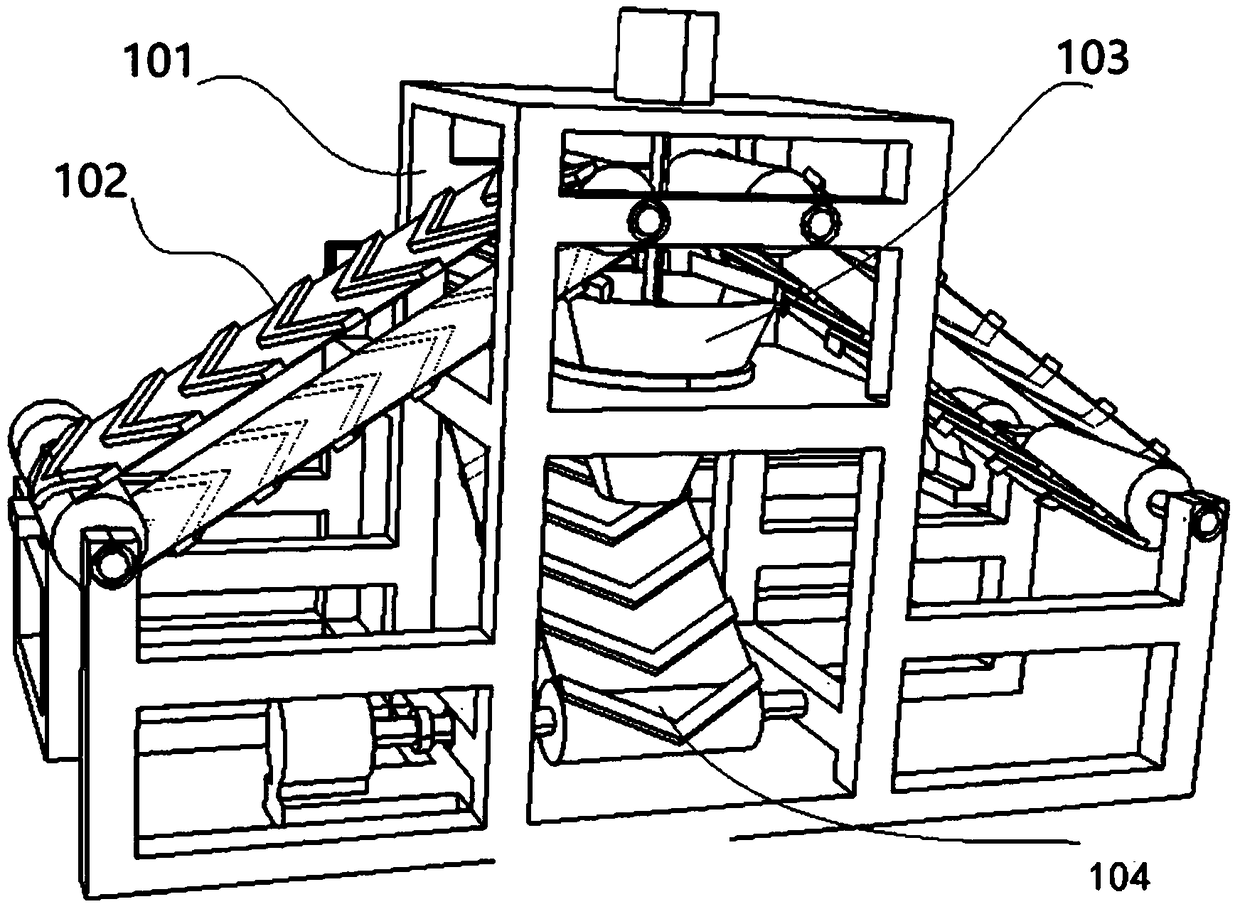

[0065] Wherein, the V-shaped automatic mixing device 1 includes a support frame 101 that is high in the middle and low on both sides. The center of the support frame 101 is provided with an upper material cylinder 103, and the diameter of the upper material cylinder 103 is larger and lower. Small, two V-shaped feeding conveyor belts 102 are arranged on the top of the upper barrel 103, and the V-shaped feeding conveyor belts 102 are installed on the support frame 101. The V-shaped feeding conveyor belts 102 are connected with the shaft of the motor, and the motor can be started. The conveyor belt that drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com