Drilling device for automotive mounting plate

A technology of drilling device and mounting plate, which is applied in the direction of feeding device, boring/drilling, drilling/drilling equipment, etc., which can solve the problem that the drilling position is easy to shift, the continuous effect cannot be achieved, and the mounting plate cannot be obtained good support etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

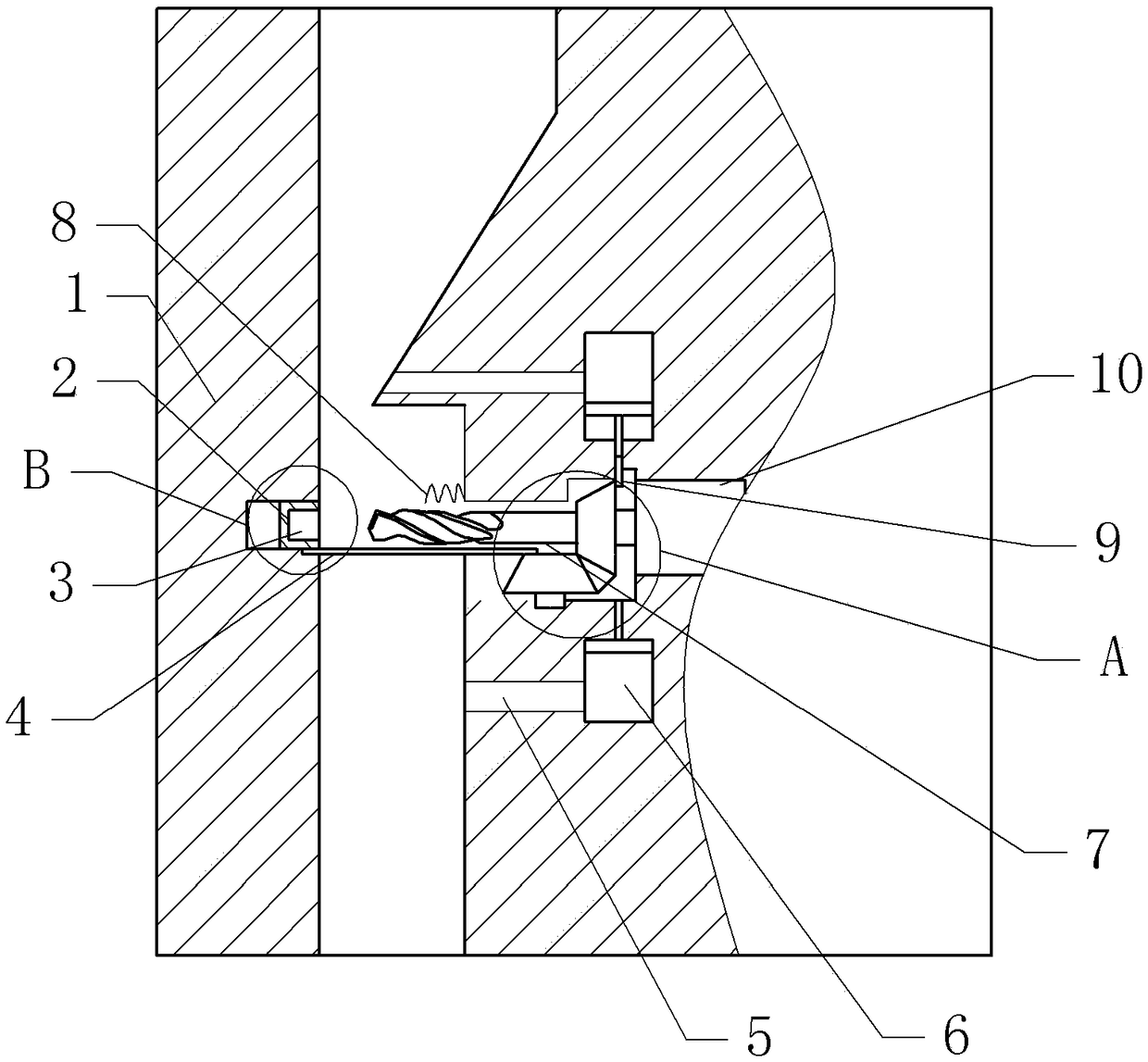

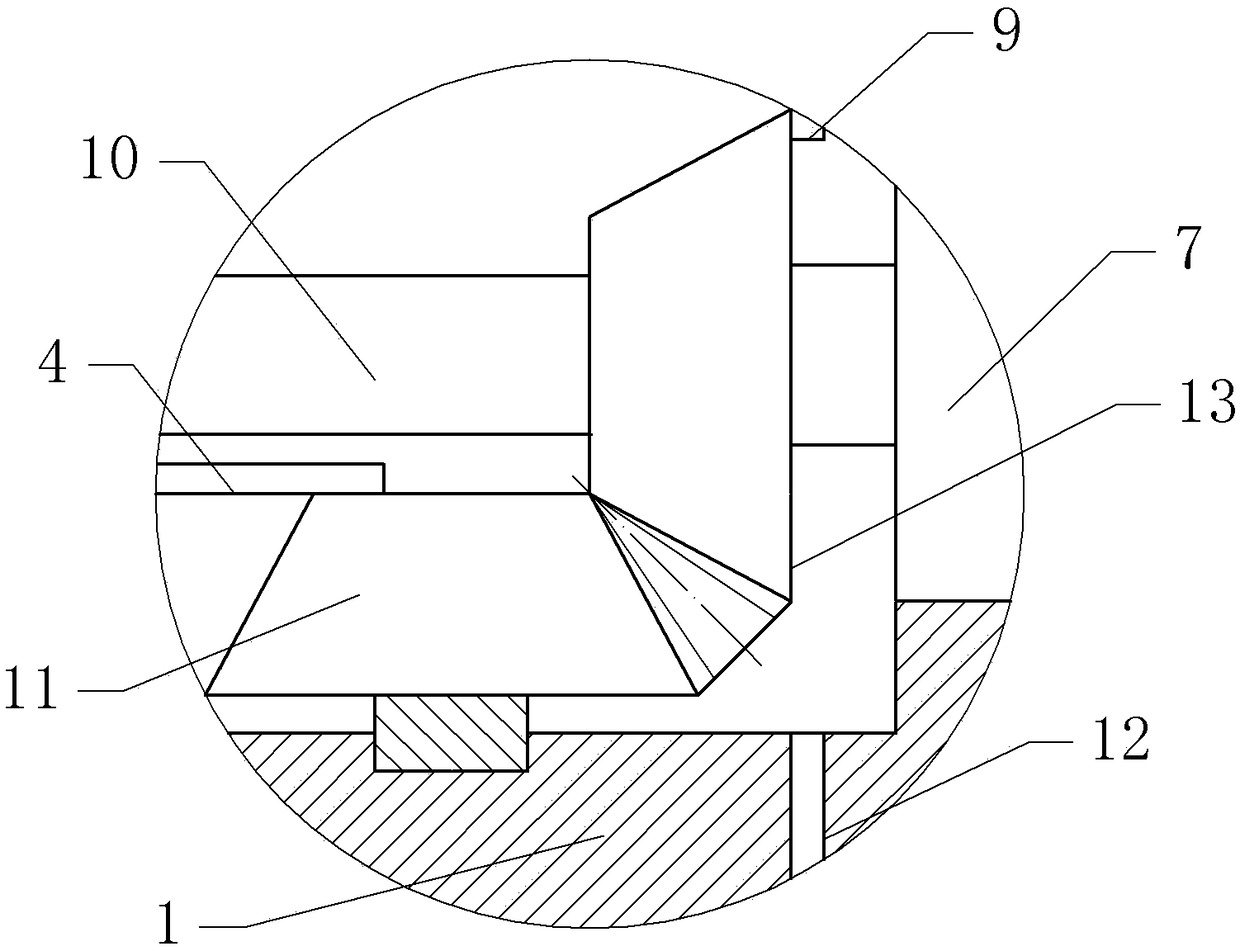

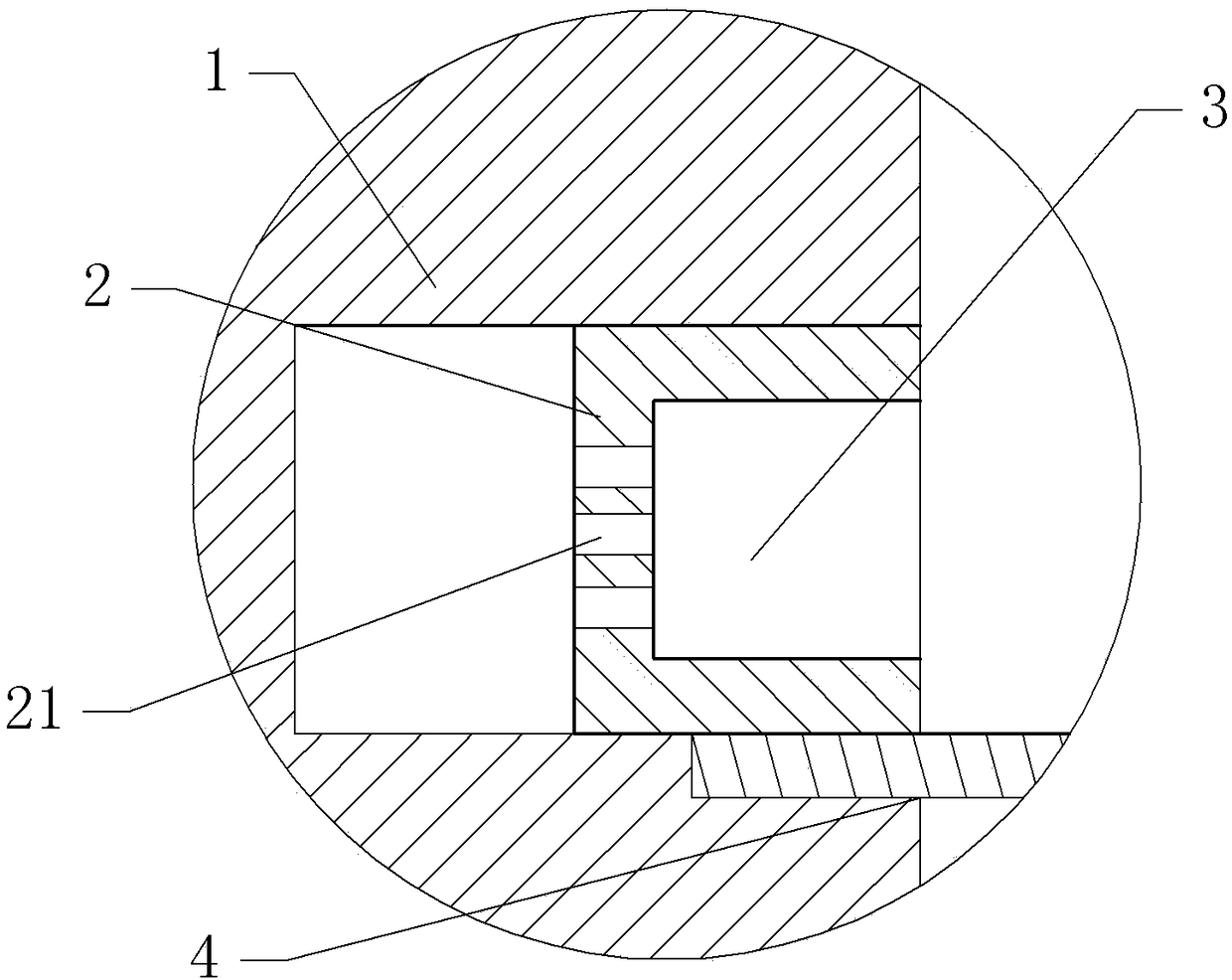

[0025] as attached figure 1 And attached figure 2 As shown, a drilling device for an automobile mounting plate includes a drilling box 1, and both sides of the drilling box 1 are provided with a feeding channel through the drilling box 1, and the upper opening of the feeding channel is away from the side outside the drilling box 1 It is an inclined surface, and the inclined surface faces downward toward the outside of the drilling box 1 .

[0026] On the drilling box 1 between the two feeding channels, a horizontally placed double-head motor 10 is fixed by fastening bolts, and the drive shafts at both ends of the double-head motor 10 are fixed with the main bevel gear 13 close to the double-head motor 10 and away from the double-head motor. Drill bit 7 for the head motor. The free end of drill bit 7 stretches in the feeding channel and, the free end of drill bit 7 is in same vertical plane with the bottom of inclined surface, and the outer periphery of drill bit 7 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com