Device for stacking and storing micropore plates and micropore plate transferring device and method

A microporous plate and storage plate technology, which is applied in the stacking, transportation and packaging of objects, can solve the problems of plates not in place, liquid easily entering the machine, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

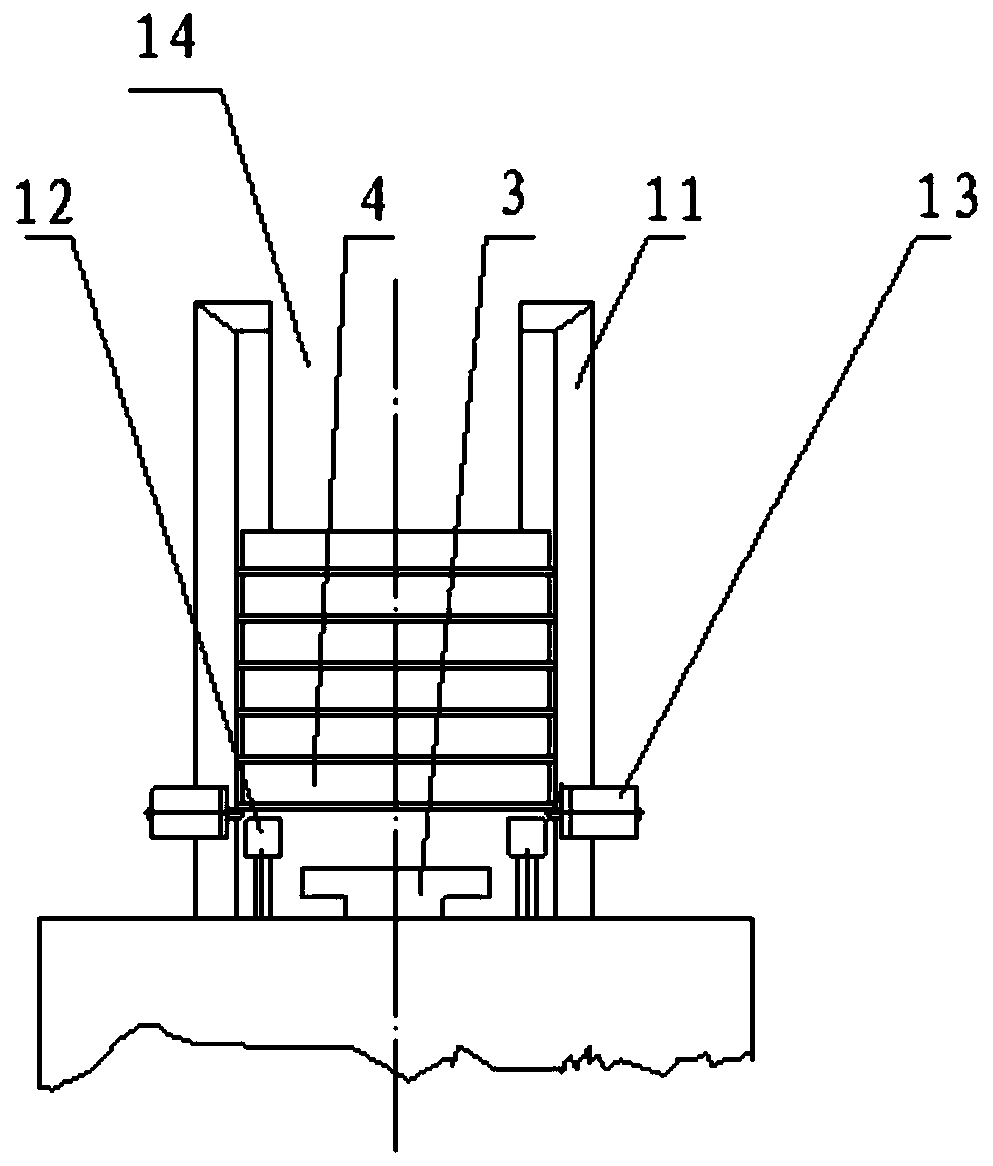

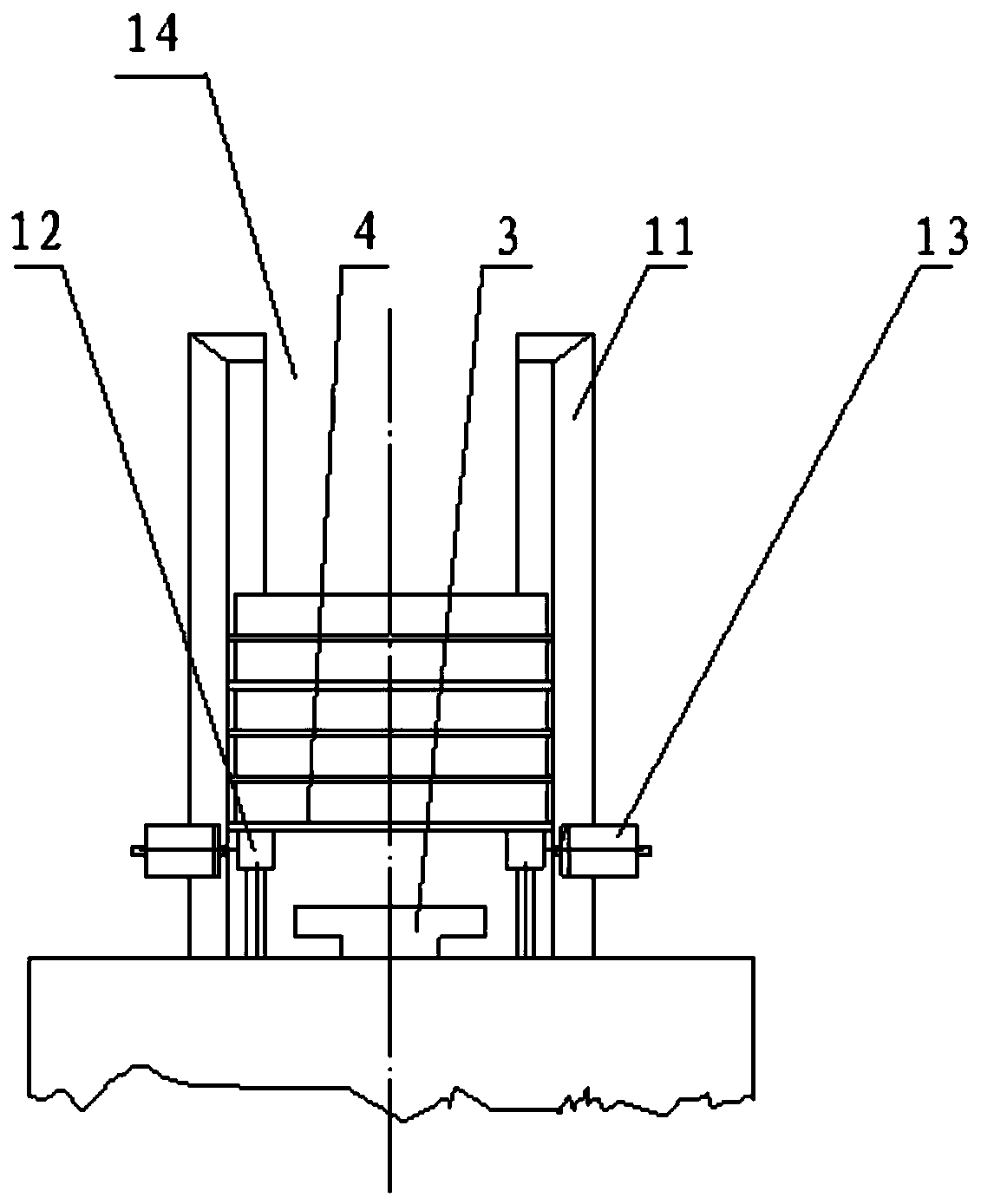

[0051] like Figure 2-9 As shown, a device for stacking and storing microplates 4 includes a plate rack 11, a lifting mechanism 12, and a plate placing part 13. The plate rack 11 includes a storage plate channel for accommodating several microplates 4 stacked up and down. 14. The plate placing part 13 is installed on the lower side of the plate placing frame 11, and the part of the plate placing part 13 can be inserted into or withdrawn from the storage plate channel 14 to carry or pass through the microporous plate 4 up and down; the lifting mechanism 12 is installed below the storage plate channel 14 Wherein the lifting mechanism 12 rises to the preset position, and the board part 13 all exits the storage board channel 14;

[0052] Specifically, in the present embodiment, there are four plate-putting parts 13, and they are installed symmetrically in pairs on the underside of the plate-putting frame 11; there are two lifting mechanisms 12, located on both sides of the moving ...

Embodiment 2

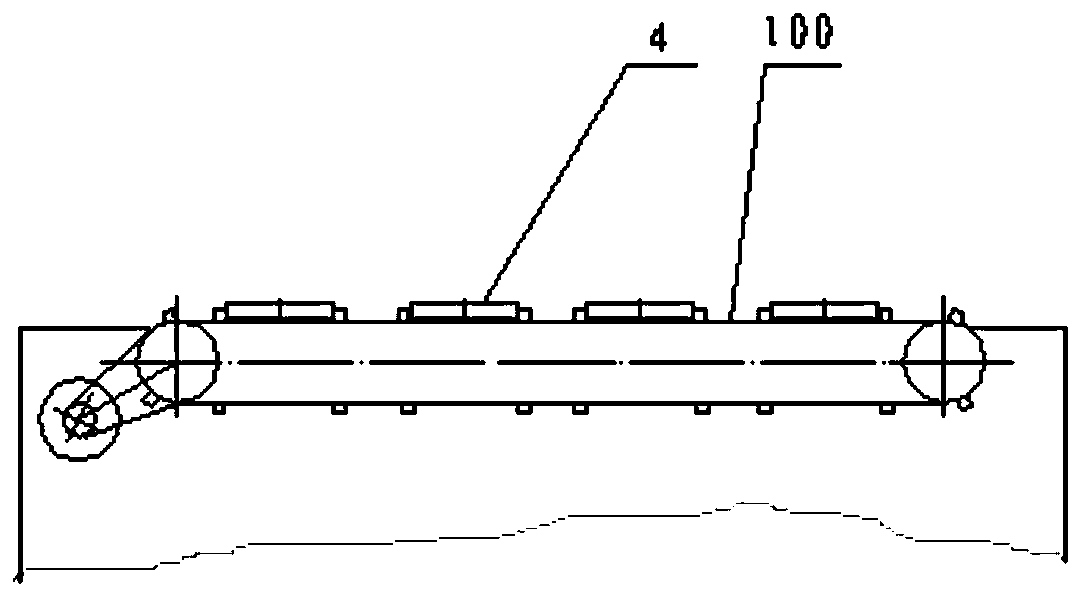

[0057] like Figure 2-9 As shown, a microplate moving device includes two devices for stacking and storing microplates according to any one of claims 1-2, which are respectively the first device 1 and the second device 2; it also includes N transfer board devices and movable mobile trays 3, N transfer board devices are distributed side by side between the first device 1 and the second device 2 in sequence; N+1 positioning slots 31 are provided on the mobile pallet 3; The positioning groove 31 is compatible with the micro-orifice plate 4;

[0058] The mobile tray 3 has two working positions when moving, and the distance is the distance from the center of the first device to the center of the first transfer board device, or the distance between two transfer board devices, or the center of the last transfer board device distance to the center of the second device,

[0059] When in the first working position, the positioning groove 31 receives the micropore plate 4 released by t...

Embodiment 3

[0078] like Figure 2-9 As shown, a method for moving a microplate is used for the above-mentioned device for moving a microplate, and the steps include:

[0079] S1: Place several microporous plates 4 stacked up and down in the first device 1, and the plate placing part 13 carries the microporous plates 4;

[0080] S2: the moving tray 3 moves to the first working position, the lifting mechanism 12 receives the microplate 4 released by the first device 1 and places the microplate 4 in the corresponding positioning groove 31;

[0081] S3: The mobile tray 3 moves to the second working position, the positioning groove 31 equipped with the micro-orifice plate 4 corresponds to the transfer plate device 6 and / or the second device 2, and then the micro-hole plate in the corresponding positioning groove 31 is moved by the lifting mechanism 12. The orifice plate 4 is separated from the positioning groove 31 and stored in the second device 2, and at the same time, the transfer plate de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com