Gravity balancing device on Z-direction working platform and cutting machine

A technology of gravity balance and workbench, which is applied in metal processing and other directions, can solve the problems of low running noise and non-self-locking of ball screw, and achieve the effects of low running noise, reduced manufacturing cost and elimination of adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

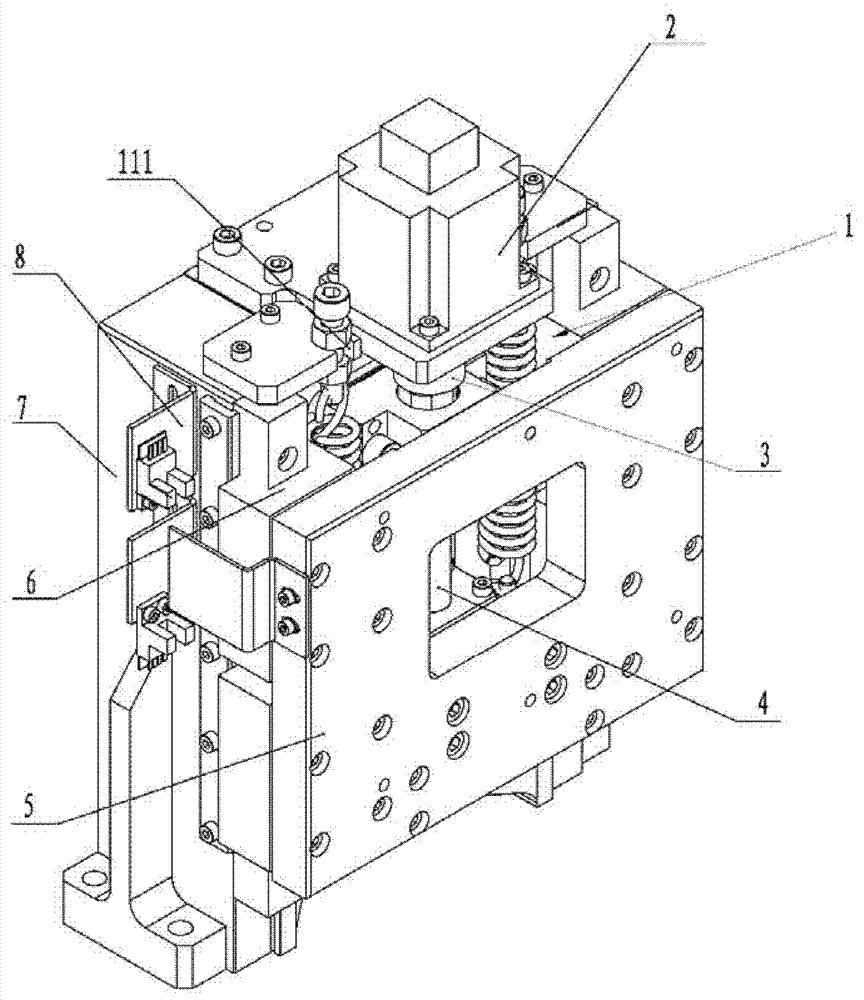

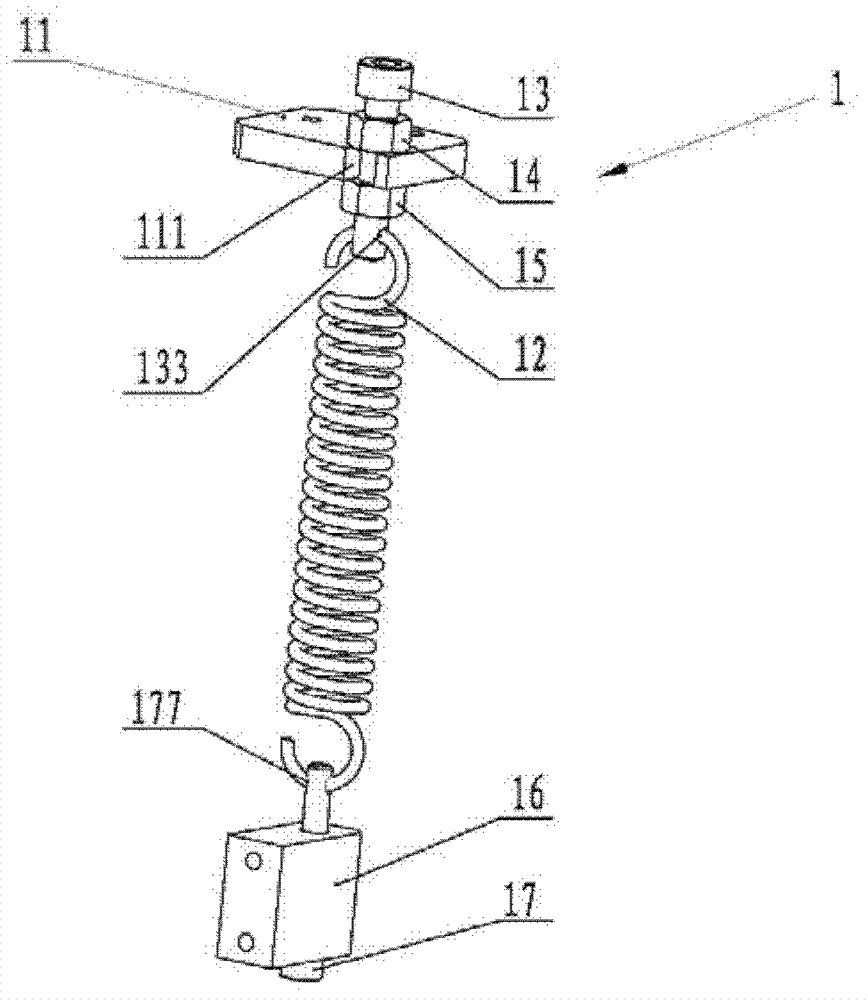

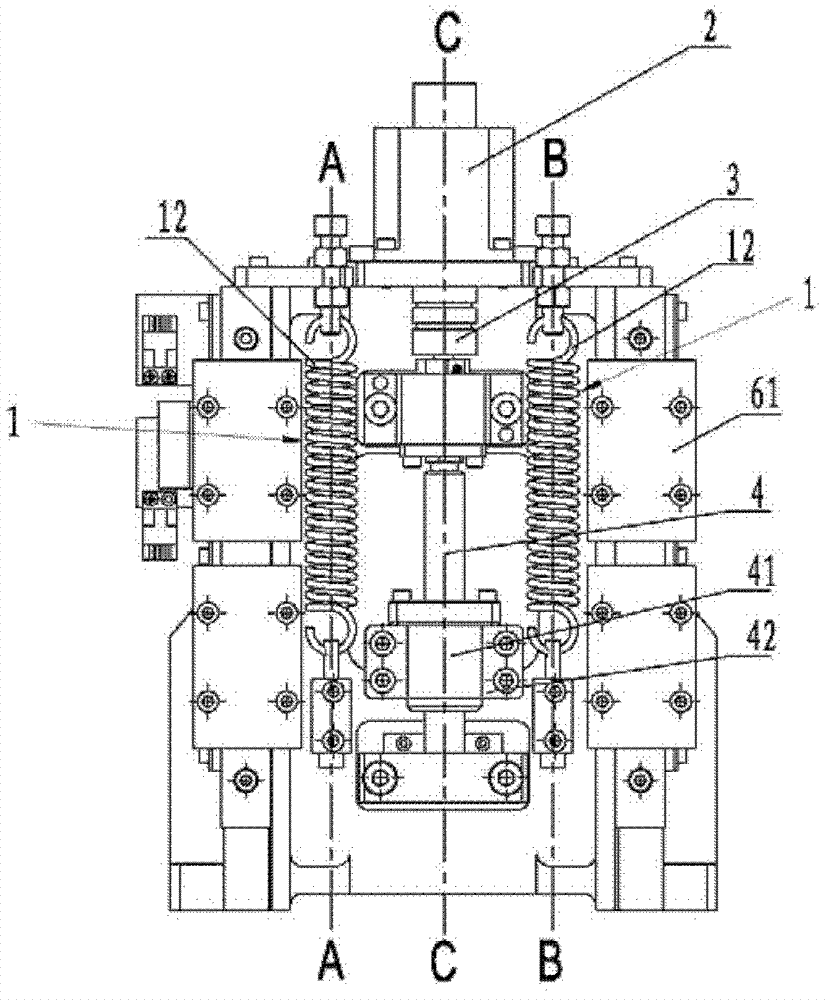

[0028] The gravity balance device on the Z-direction workbench of the present invention, the Z-direction workbench includes a base, a lead screw rotatably mounted on the base, and a sliding plate that can move relative to the base through the rotation of the lead screw is installed on the lead screw. The balancing device includes an elastic device fixed on the base and providing upward force to the slide.

[0029] Wherein, the elastic device can be a tension spring or a spring, or other devices with elastic coefficients. Elastic device is extension spring among the present embodiment, and the upper end of extension spring is fixed on the base, and the lower end of extension spring is fixed on slide plate.

[0030] When the sliding plate (moving part) of the Z-direction workbench reciprocates, the elastic device fixed on the base provides an upward force to the sliding plate to balance the downward gravity of the moving load, which solves the problem that the screw cannot be se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com