Smoke dust treatment device for large casting equipment and use method of smoke dust treatment device

A casting equipment and processing device technology, which is applied in the field of smoke and dust processing devices for large casting equipment, can solve the problems of inconvenient dust cleaning, easy to affect the normal exhaust of exhaust pipes, etc., and achieve the effect of increasing sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

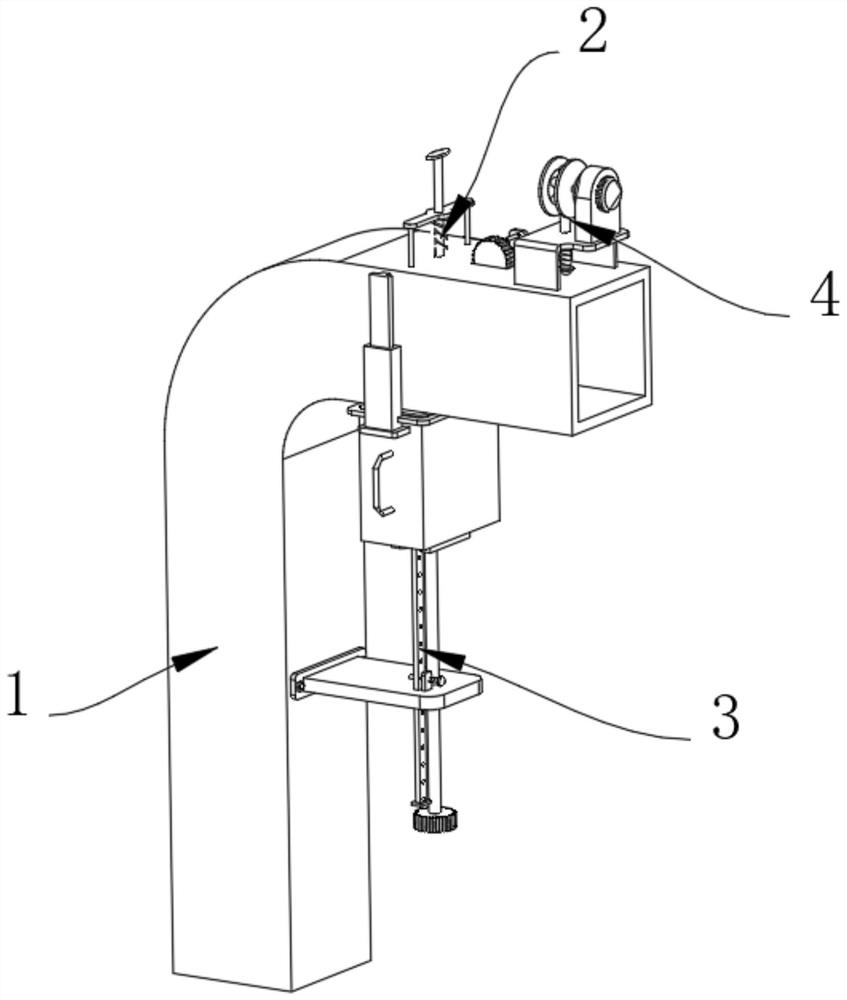

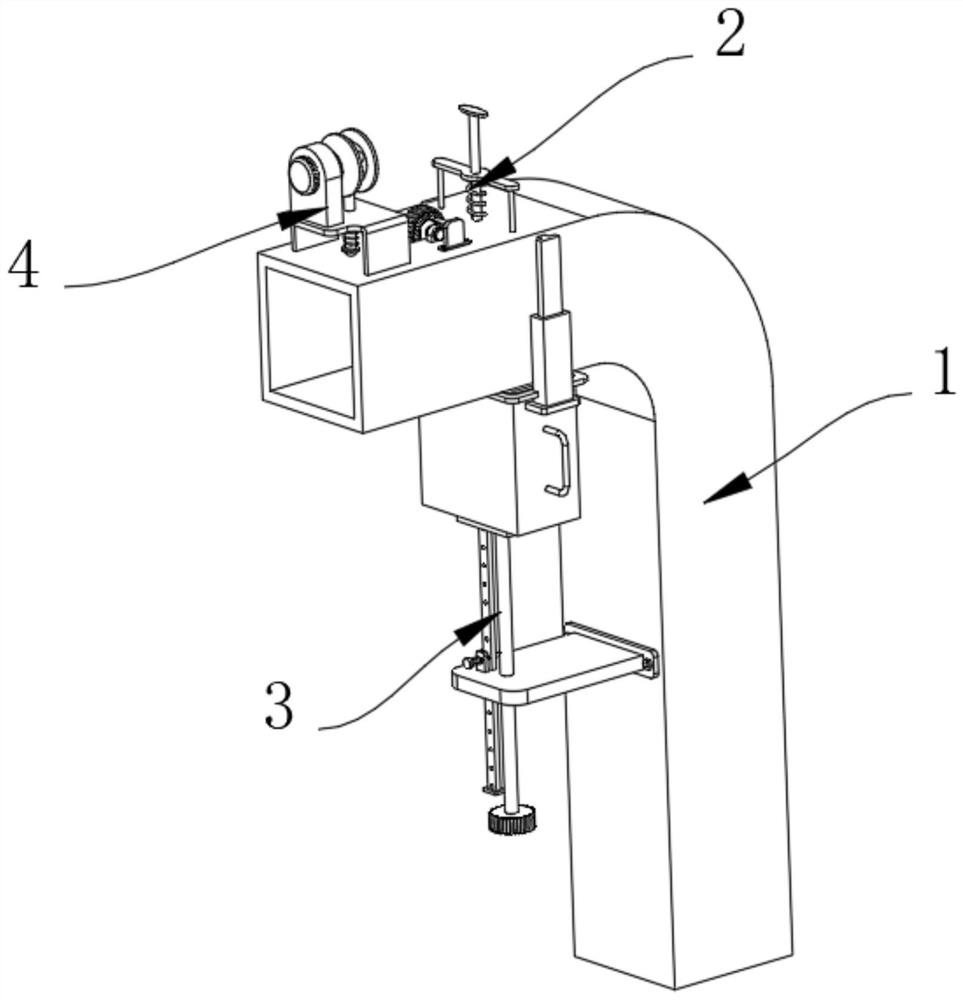

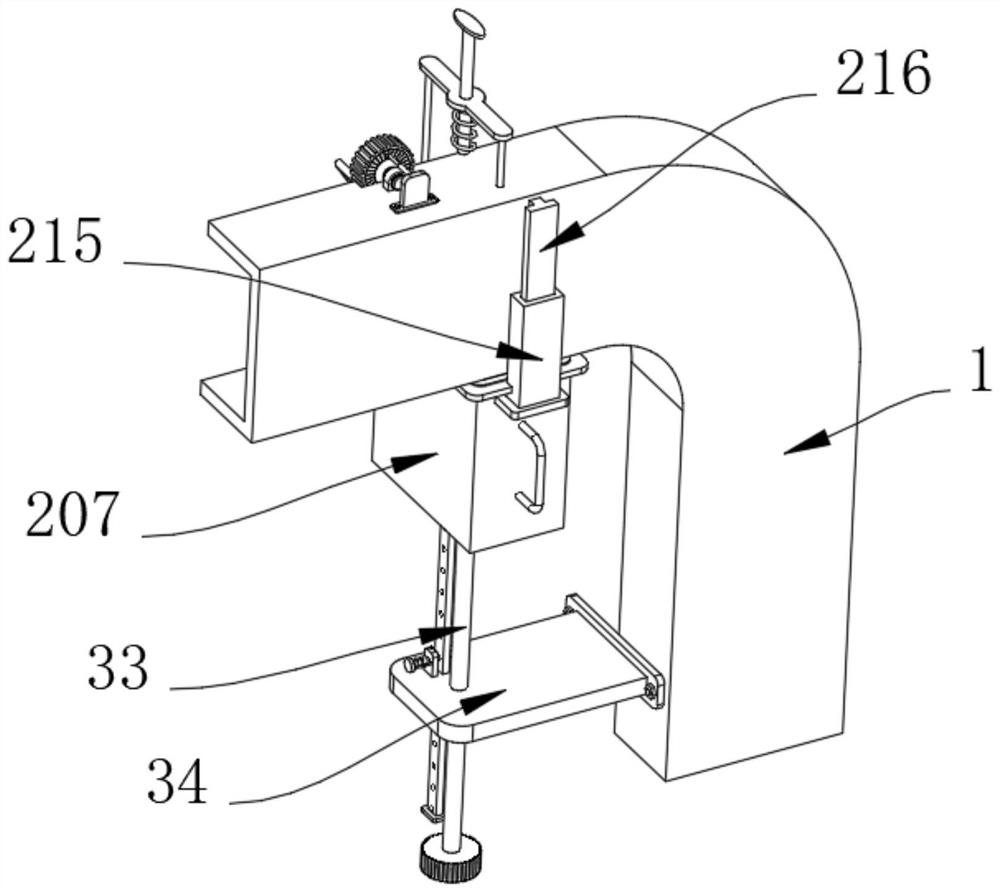

[0047] Example 1, as Figure 1-8 As shown, the present invention provides a fume treatment device for large-scale foundry equipment and a method of using the same, comprising a fume exhaust pipe 1, a support structure 3 and a filter structure 2, and the upper surface of the short arm end of the exhaust pipe 1 is provided with a filter structure 2 , the lower end of the collection box 207 is provided with a support structure 3 , and the upper surface of the short arm end of the smoke exhaust pipe 1 is provided with an auxiliary structure 4 .

[0048] The specific settings and functions of the filter structure 2 , the support structure 3 and the auxiliary structure 4 will be described in detail below.

[0049] like image 3 and Figure 4 As shown, the filter structure 2 includes a motor 201, the motor 201 is fixedly connected to the surface of the smoke exhaust pipe 1, the output end of the motor 201 is fixedly connected with a gear A202, the smoke exhaust pipe 1 is provided w...

Embodiment 2

[0053] Embodiment 2, on the basis of embodiment 1, as Figure 7 and Figure 8As shown, the auxiliary structure 4 includes a fixing frame 41, the fixing frame 41 is fixedly connected to the surface of the smoke exhaust pipe 1, a top rod 42 is slidably inserted in the fixed frame 41, and the lower end of the top rod 42 is fixedly connected to be used for knocking the smoke exhaust pipe 1, the circular arc surface of the ejector rod 42 is covered with a spring C44, the two ends of the spring C44 are respectively fixedly connected with the ejector rod 42 and the tapping block 43, and the upper surface of the fixing frame 41 is fixedly connected with a mounting block 45, The mounting block 45 is fixedly connected with a motor 46 for driving, and the output end of the motor 46 is fixedly connected with an adjusting member 47 for adjusting the reciprocating motion of the ejector rod 42, so that the position of the ejector rod 42 can be quickly adjusted by means of the adjusting membe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com