Crosswound bobbin and method for producing such a bobbin

A cross-winding bobbin and bobbin technology, which is applied in the cross-winding bobbin and its manufacturing field, can solve the problems of narrowing the laying width, loss of precision winding, and lack of appearance shape, etc., to achieve outstanding unwinding performance and improved unwinding performance , the effect of uniformity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

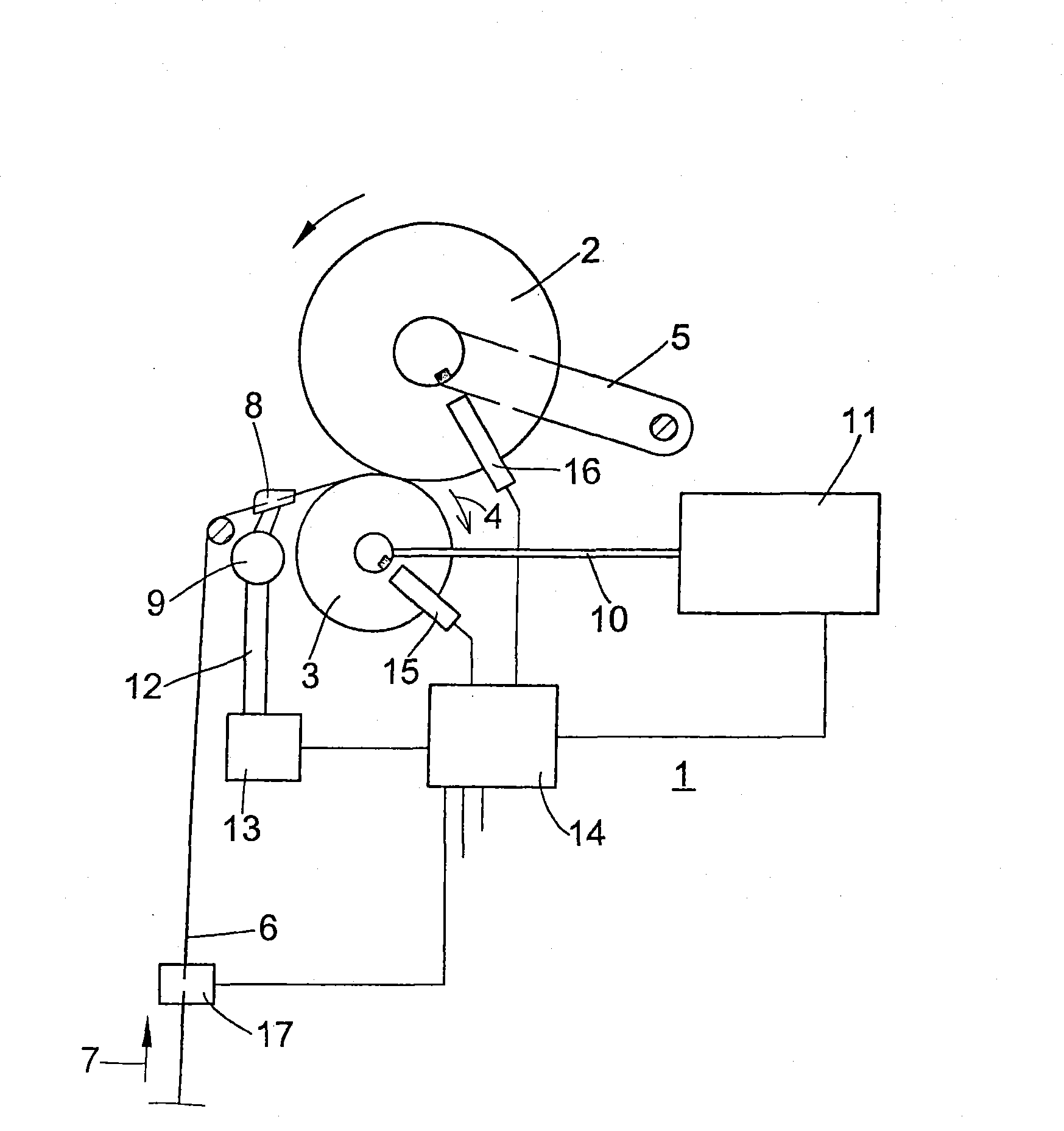

[0039] in such as figure 1 In the shown winding mechanism 1 of the winding station for producing cross-wound bobbins, a cross-wound bobbin 2 is driven by a friction roller 3 rotating in the direction of arrow 4 . The cross-wound bobbins 2 are held in a rotatable creel 5 and rest on friction rollers 3 . Yarn 6 is conveyed in the direction of arrow 7 . The yarn 6 passes through a yarn guide 8 that moves back and forth in the axial direction of the cross-winding bobbin 2 and is wound onto the cross-winding bobbin 2 . The yarn guide 8 is driven by means of a reciprocating mechanism 9 . The friction roller 3 is driven by an electric motor 11 via a shaft 10 . The reciprocating mechanism 9 is connected with a motor 13 through an effective connecting piece 12 . Motor 11 and motor 13 are controlled by microprocessor 14 . The microprocessor 14 includes a program for controlling the laying distance of the yarn 6 according to the actual diameter of the cross-wound bobbin 2 . The act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com