A high-efficiency power generation wheel using tire running deformation

A tire and high-efficiency technology, applied in the direction of wheels, electrical components, electromechanical devices, etc., can solve the problems of difficult tires, low power generation efficiency, different vibration and shock frequencies and uncertainties in the amount of deformation, and achieve large strokes and improve power generation efficiency. , the effect of fast reciprocating motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the drawings.

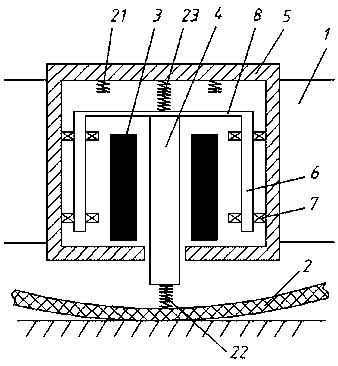

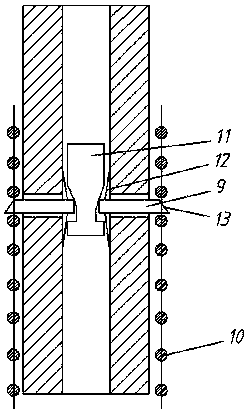

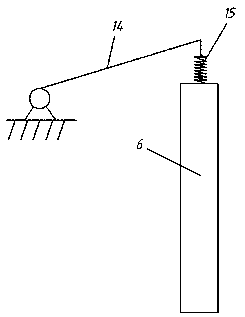

[0028] See figure 1 The present invention uses tires to deform and efficiently generate power wheels. The tires are composed of a rim 1 and a rubber carcass 2. Several sets of linear generators are provided along the circumference of the tire, and each set of linear generators includes a matched stator 3 and a mover. 4. The stator 3 is located in the casing 5, and the casing 5 is fixedly installed on the rim 1. The stator 3 is formed by winding coils on a skeleton formed by stacking silicon steel sheets or other materials, and the axis of the stator 3 is in the tire diameter direction. The mover 4 is composed of a skeleton and a permanent magnet or an excitation coil mounted on the skeleton. The two ends of the mover pass through the stator, one end passes through the casing 5 and faces the rubber carcass 2 after passing through the stator 3, and the other end is located in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com