In-tube liquid drop preparing chip device

An internal droplet and chip technology, applied in the field of biochemical microfluidics, can solve problems such as complexity, difficulty in miniaturization of devices, increase in complexity of chip devices, etc., and achieve the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

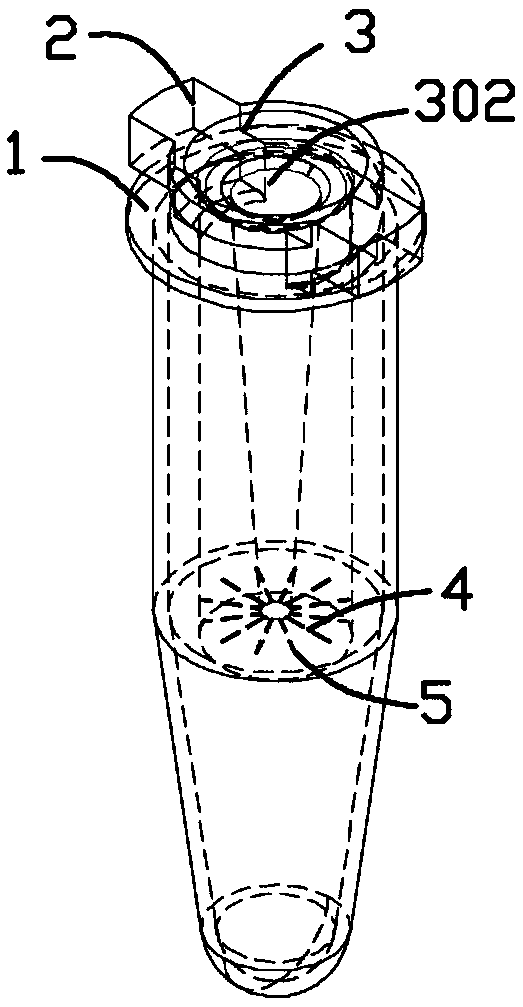

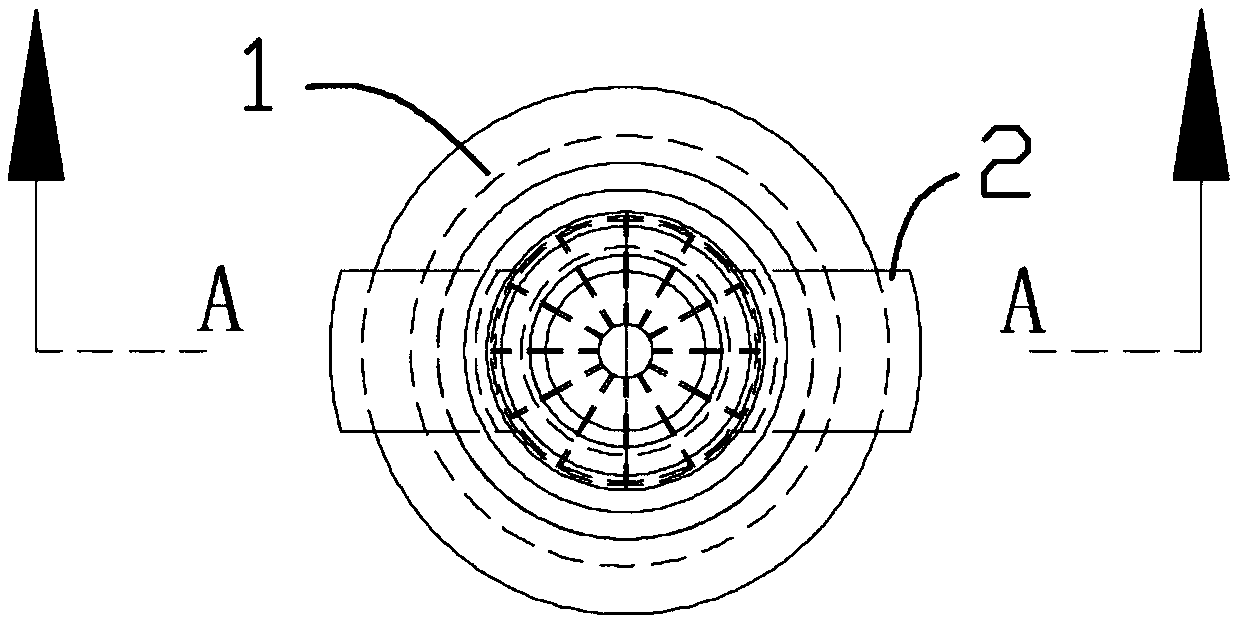

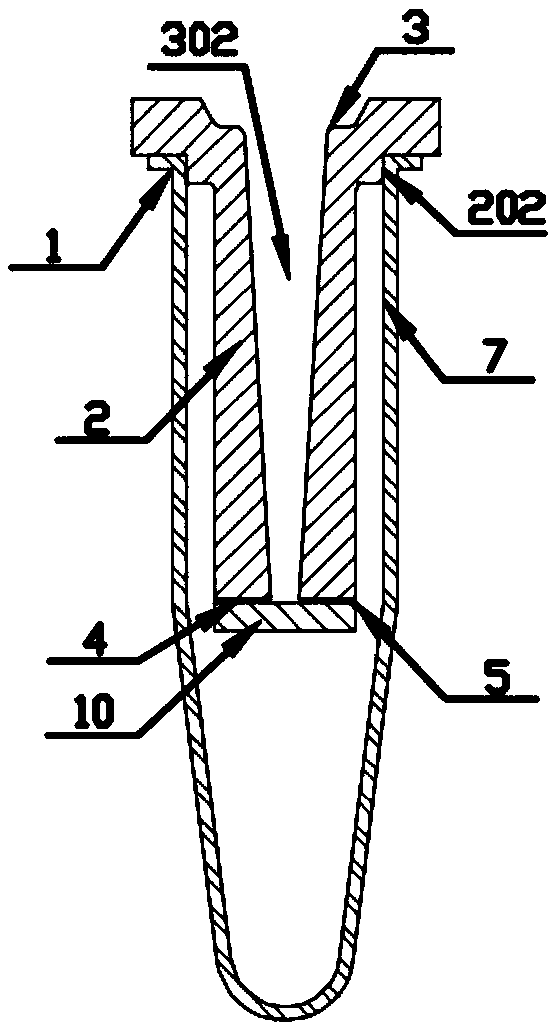

[0041] Embodiment 1, with reference to figure 1 , Figure 2-1 , Figure 2-2 , image 3 , Pic 4-1 , Figure 4-2 , a droplet preparation chip device in a tube, including a reaction tube 1 and a droplet generation chip 2 assembled therewith, the reaction tube 1 adopts a centrifuge tube or a PCR tube commonly used in a laboratory, and cooperates with the droplet generation chip 2 to complete droplet generation, It also serves as a container for droplet collection and reaction. The following is an example of a 0.5mL centrifuge tube; the droplet generation chip 2 is a stepped cylindrical structure, which is used for droplet preparation after being assembled with the reaction tube 1; The droplet generation chip 2 has a plurality of branch microchannels 4 with the same size and structure connected to the reagent inlet 3. The branch microchannels 4 are parallel to the bottom of the droplet generation chip 2 and radially distributed from the center of the chip to the outside. The b...

Embodiment 2

[0050] Embodiment 2, with reference to Figure 5 , Figure 6-1 and Figure 6-2 , a chip device for preparing liquid droplets in a tube, including a reaction tube 1 and a droplet generating chip 2; in order to realize large-scale liquid droplet preparation and mass production of chip devices, the reaction tube 1 passes through the first connecting plate structure 101 in eight The reaction tube 1 adopts a flat-bottomed truncated conical tube to reduce the consumption of continuous phase reagents; at the same time, the droplet generation chip 2 is also made in eight rows through the second connecting plate structure 201, and is connected with the The reaction tube 1 is assembled to prepare 8 groups of dispersed phase reagents 9 droplets at the same time. There is a distance between the bottom of the droplet generation chip 2 and the bottom of the reaction tube 1 for the storage of droplets 6 or continuous phase reagents 8 .

[0051] The reaction tube 1 and the droplet generatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com