Water-in-oil transparent crude emulsion with phase separation and application thereof

A water-in-oil, coarse-emulsion technology, applied in the determination/inspection of microorganisms, biochemical equipment and methods, etc., can solve problems such as pollution and increased probability of false positives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

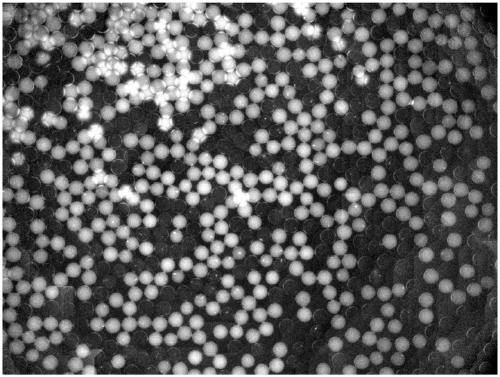

[0080] The preparation method of transparent macroemulsion droplet among the present invention, described transparent macroemulsion droplet is the stable spherical particle that above-mentioned water phase liquid is emulsified and dispersed in oil phase and forms, and its preparation method generally comprises the following steps: (1) respectively Prepare water phase (containing refractive index enhancer, etc.) and oil phase (lipophilic surfactant) liquid, (2) emulsify and disperse to form transparent coarse emulsion droplets.

[0081] The method of emulsifying and dispersing the water phase into the oil phase to form droplets can be oscillating emulsification, micro-flow cross co-flow method or T-shaped flow channel droplet method or centrifugal droplet emulsification in the prior art (such as reference [10]). With these methods, droplets with adjustable diameter and good uniformity can be obtained.

[0082] In addition, different oil phases can be selected for different drop...

Embodiment 1

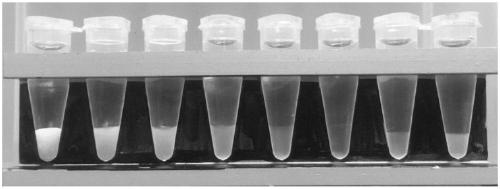

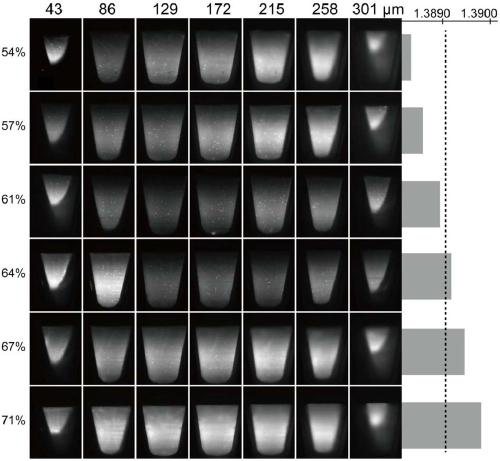

[0090] In order to verify the appropriate concentration of refractive index enhancer, Gelest DMS-T01.5 silicone oil and surfactant DowCorning ES5612 were prepared according to the mass ratio of 19:1, mixed evenly and centrifuged at 20,000rcf for 10 minutes to obtain the supernatant for use emulsified oil in the next step. Betaine in the water phase is a refractive index enhancer. The volume of the water phase of each sample is 20 μL, and 240 μL of the above-mentioned prepared oil is added to the system. figure 1 Shown from left to right is the situation of adding 0.5, 1.0, 1.5, 2.0, 2.5, 3.0, 3.5, 4.0 moles of refractive index enhancers respectively (the concentration here refers to the concentration in the finally formed water-oil mixture) . Depend on figure 1 It can be seen that as the concentration of the refractive index enhancer increases, the transparency first increases and then decreases, and is most transparent when the concentration of the refractive index enhancer...

Embodiment 2

[0092] The difference from Example 1 is that glycine is used as the refractive index enhancer. Glycine solutions with different concentrations (0.5, 1, 1.5 mol / liter) were centrifuged to form coarse emulsion droplets. As the concentration of glycine increases, the transparency first increases and then decreases, and the most transparent is when the concentration of the refractive index enhancer is 2.8 moles per liter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com