Wafer with edge stepped/gentle slope type protection ring and manufacturing method thereof

A manufacturing method and technology of guard ring, which are applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problem of inability to apply simultaneous metal deposition process on both sides of thin wafers, and inability to perform photoresist spin coating process in yellow light process , the problem of inability to apply the proximity yellow light process, etc., to reduce the transfer steps, save the process time, and improve the yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

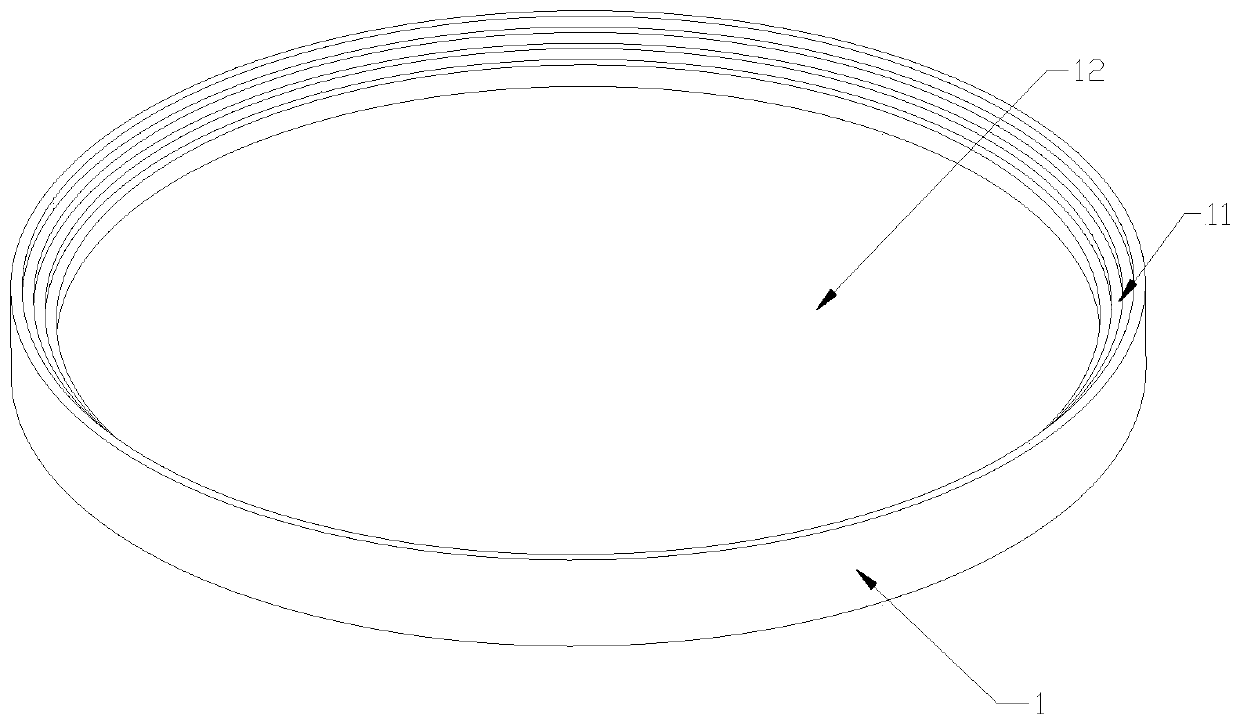

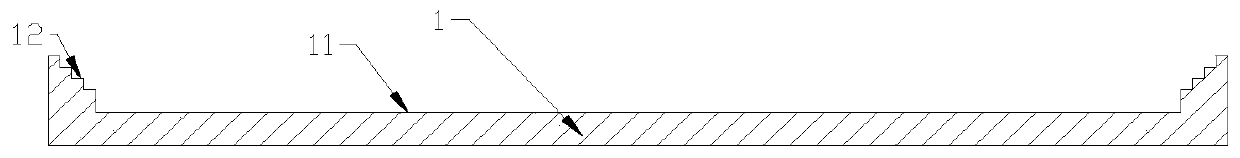

[0031] A method for manufacturing a wafer with an edge-stepped / gentle-slope guard ring, comprising the following steps:

[0032] Step 1: Paste the grinding film on the front of the wafer;

[0033] Step 2: Grind the back of the wafer, grind the thickness of the back of the ground wafer to 150-400 microns, lift and remove the grinding film;

[0034] Step 3: Use etching equipment, configure automatic thickness measurement, etchant concentration and flow control by etching process, and blocker is automatically controlled by the program to scale and protect the edge blocking ring / edge configuration with inert fluid nozzle dilution to reduce the amount of edge etching;

[0035] Step 4: Etching the back of the wafer to generate a protective ring with a width of 3-10 mm;

[0036] Step 5: Etching step by step, so that the height of the protection ring is gradually reduced from the outside to the inside, the protection ring is formed into a ladder shape, and the thickness of the wafer ...

Embodiment 2

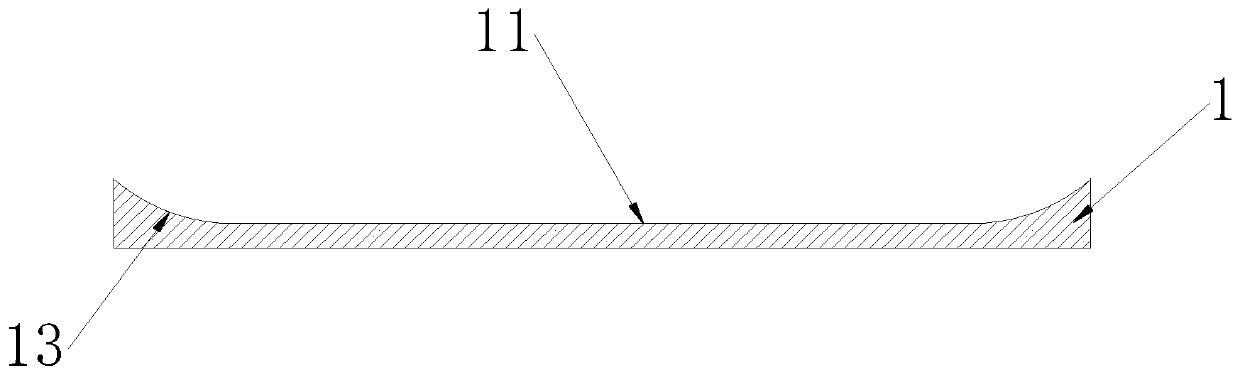

[0038] A method for manufacturing a wafer with an edge-stepped / gentle-slope guard ring, comprising the following steps:

[0039] Step 1: Paste the grinding film on the front of the wafer;

[0040] Step 2: Grind the back of the wafer, grind the thickness of the back of the ground wafer to 150-400 microns, lift and remove the grinding film;

[0041] Step 3: Use etching equipment, configure automatic thickness measurement, etchant concentration and flow control by etching process, and blocker is automatically controlled by the program to scale and protect the edge blocking ring / edge configuration with inert fluid nozzle dilution to reduce the amount of edge etching;

[0042] Step 4: Etching the back of the wafer to generate a protective ring with a width of 3-10 mm;

[0043] Step 5: Etching step by step, so that the height of the protection ring is gradually reduced from the outside to the inside, the protection ring forms a gentle slope shape, and the thickness of the wafer ins...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com