Pretreatment device for multiple samples for continuous flow analysis and application method of device

A technology for sample pretreatment and flow analysis, applied in the field of tobacco chemistry research, can solve problems such as affecting the progress of the detection work, not being simple enough, and affecting the efficiency of the detection work, saving time and manual operation intensity, reducing the introduction of human errors, and reducing the sample The effect of simplifying the pre-processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0051] Embodiment: Determination of total sugar in flue-cured tobacco sample

[0052] Sample preparation: first dry the tobacco leaves (or shredded tobacco), and use a high-speed cyclone mill to break the cell walls of tobacco and tobacco products, then pass through a 60-mesh sieve, seal and store as a preparation sample. Test the water content of the sample according to the YC / T31-1996 standard. Proceed as follows:

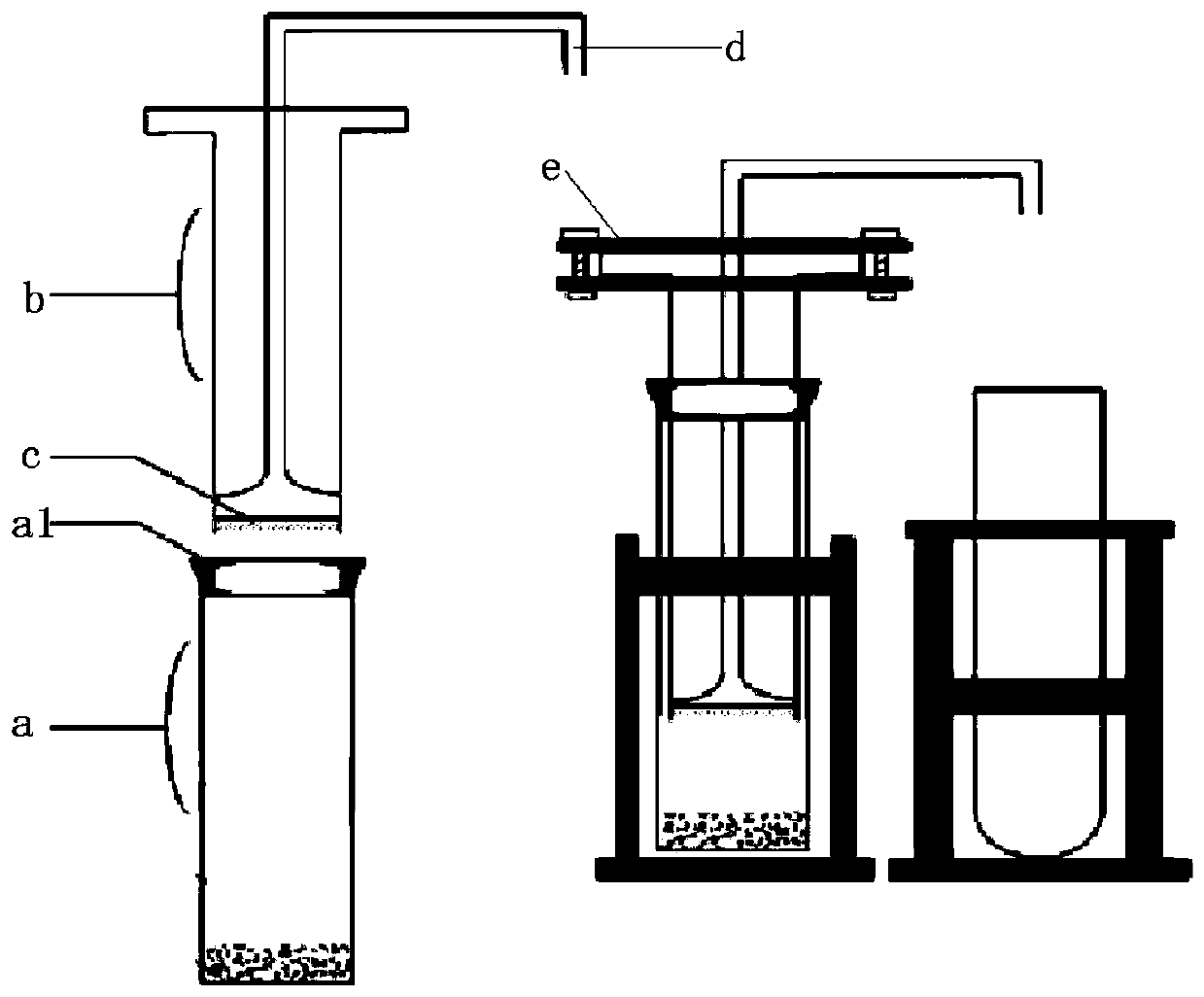

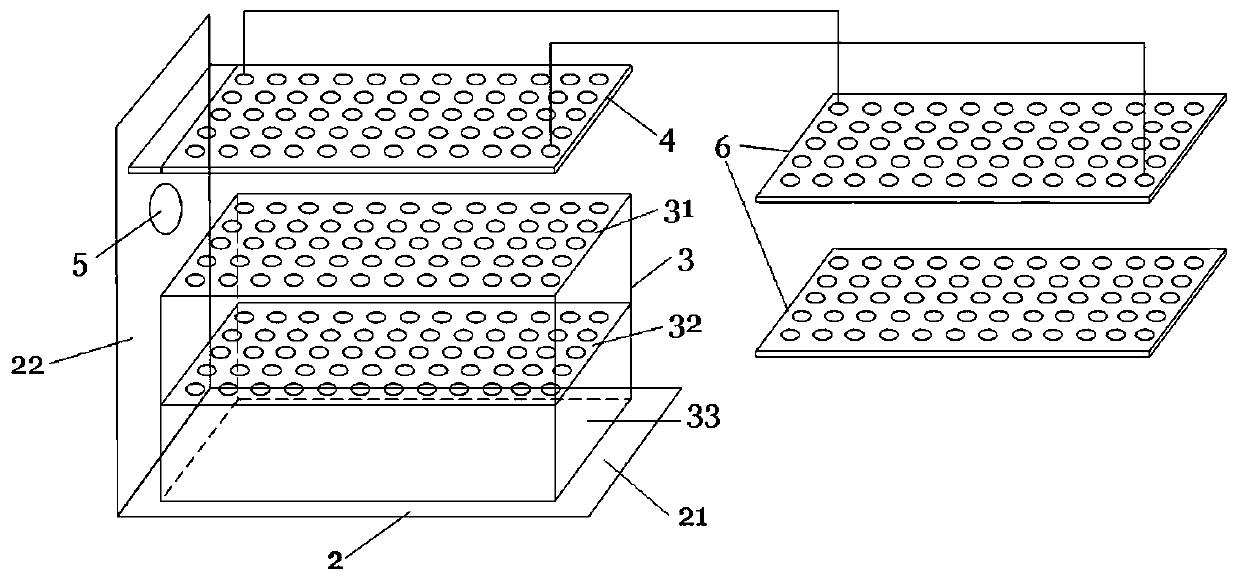

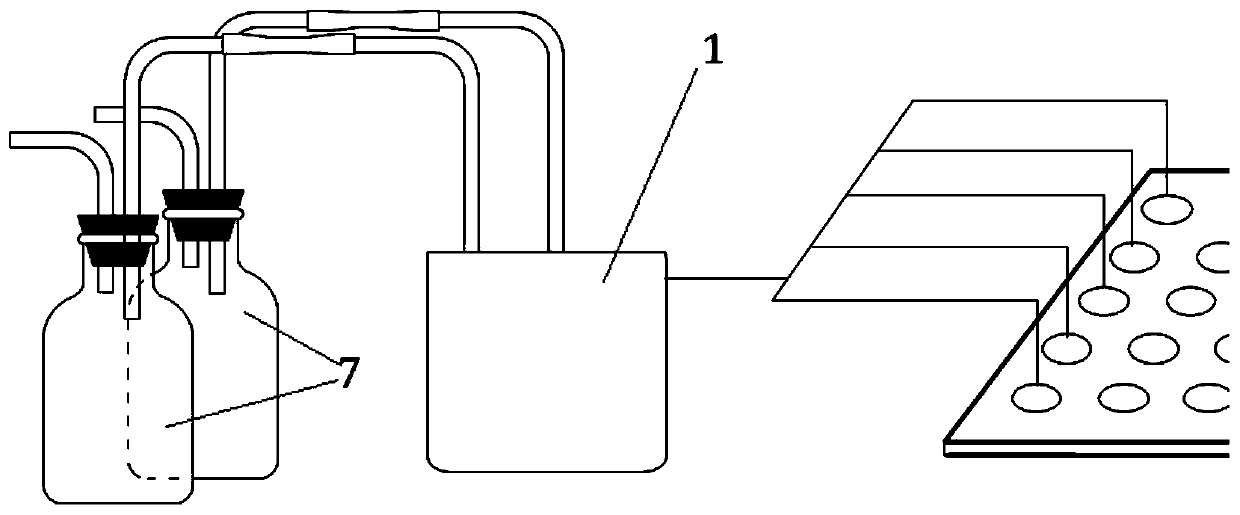

[0053] A. Put 60 extraction tubes into the holes of the extraction tube rack respectively, weigh 0.25g tobacco leaf (or shredded tobacco) samples into the extraction tubes, set the volume of reagents to be added to each extraction tube, and use multi-channel automatic liquid addition Add the reagents in the reagent storage bottle into the extraction tube respectively, and put on the sealing ring;

[0054] B. Place the extraction tube rack on the shaker, perform vibration extraction according to the oscillation extraction conditions selected by the standard meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com