Speed reducer layout structure used for range-extending type electric vehicle

A technology of layout structure and electric vehicle, which is applied to electric power devices, power devices, control devices, etc., can solve the problems of large size and mass of generators, low energy density of generators, and low speed of generators, and achieve obvious energy saving effect. , the effect of reducing battery usage and high power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

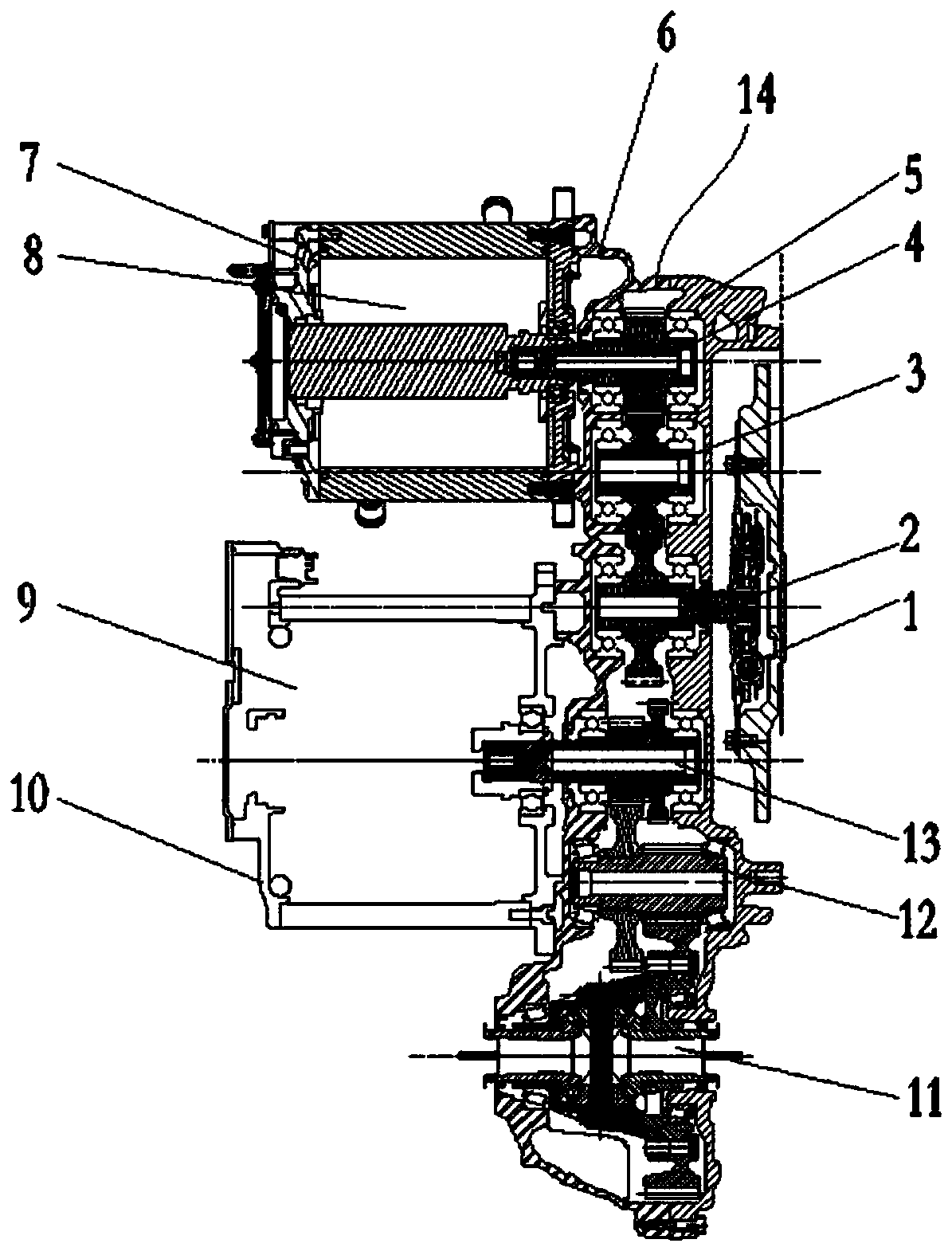

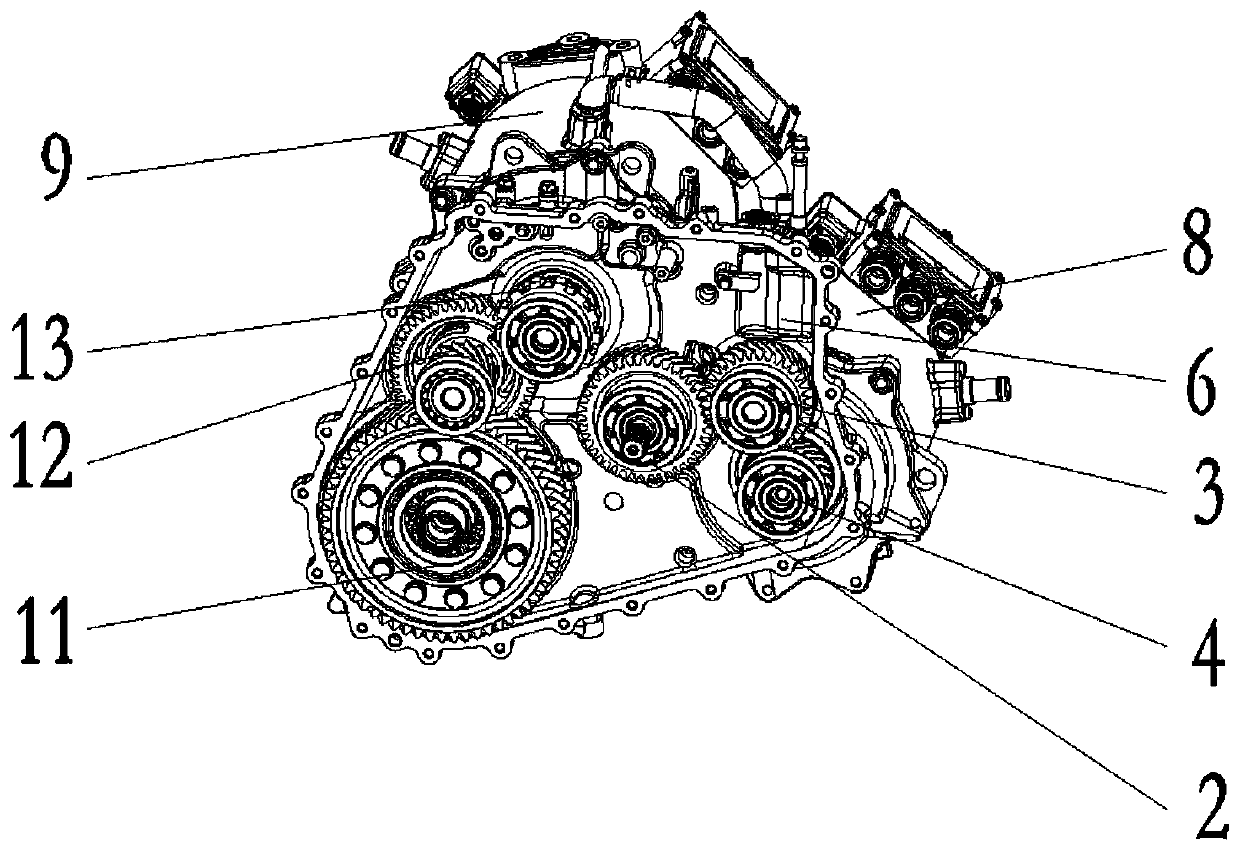

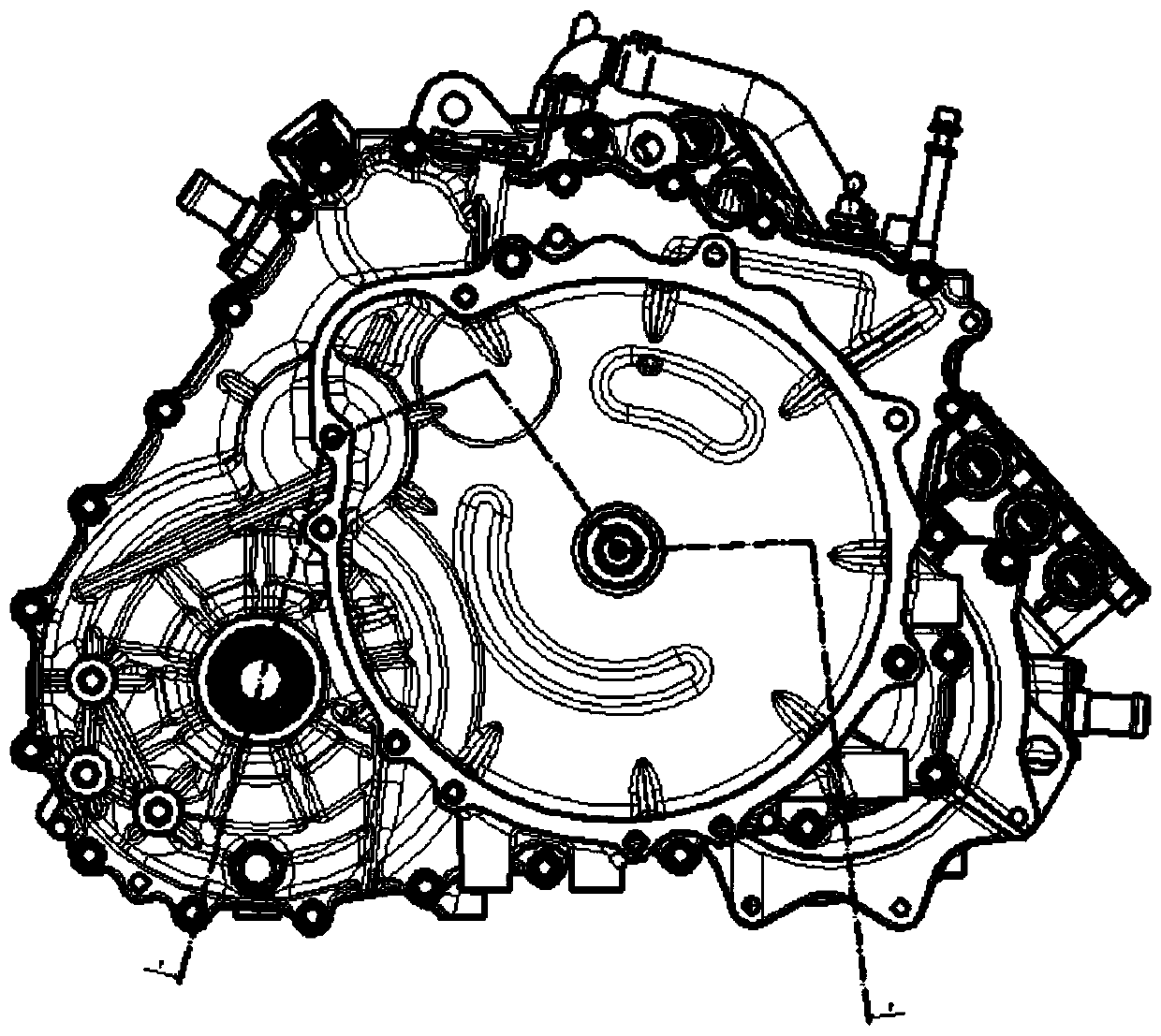

[0019] Specific implementation mode one: combine Figure 1-Figure 3 Describe this embodiment, a reducer layout structure of a range-extended electric vehicle in this embodiment includes a dual-mass flywheel 1, a generator input shaft 2, an idler shaft 3, a generator output shaft 4, a front housing 5, and a rear housing 6. Generator housing 7, generator 8, motor 9, motor housing 10, differential 11, output shaft 12, input shaft 13, engine and dual mass flywheel 1 are connected by bolts, dual mass flywheel 1 and generator The input shaft 2 is connected by a spline, the generator input shaft 2 is meshed with the idler shaft 3 through a gear, the idler shaft 3 is meshed with the generator output shaft 4 through a gear, the generator output shaft 4 is connected with the rotor of the generator 8 by a spline, The electric energy sent by the generator 8 is transmitted to the power battery and the motor 9. The motor 9 is connected to the input shaft 13 through a spline. The input shaft...

specific Embodiment approach 2

[0027] Specific implementation mode two: combination Figure 1-Figure 3 The present embodiment is described. In the reducer layout structure of the range-extended electric vehicle of the present embodiment, cooling channels for cooling the generator 8 and the motor 9 are respectively arranged on the generator housing 7 and the motor housing 10 . In this way, the cooling channels distributed on the generator housing 7 and the motor housing 10 can cool the generator 8 and the motor 9, reduce the heat generated by their work, and improve the working efficiency and service life.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com