Patents

Literature

38results about How to "Reduce vehicle quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

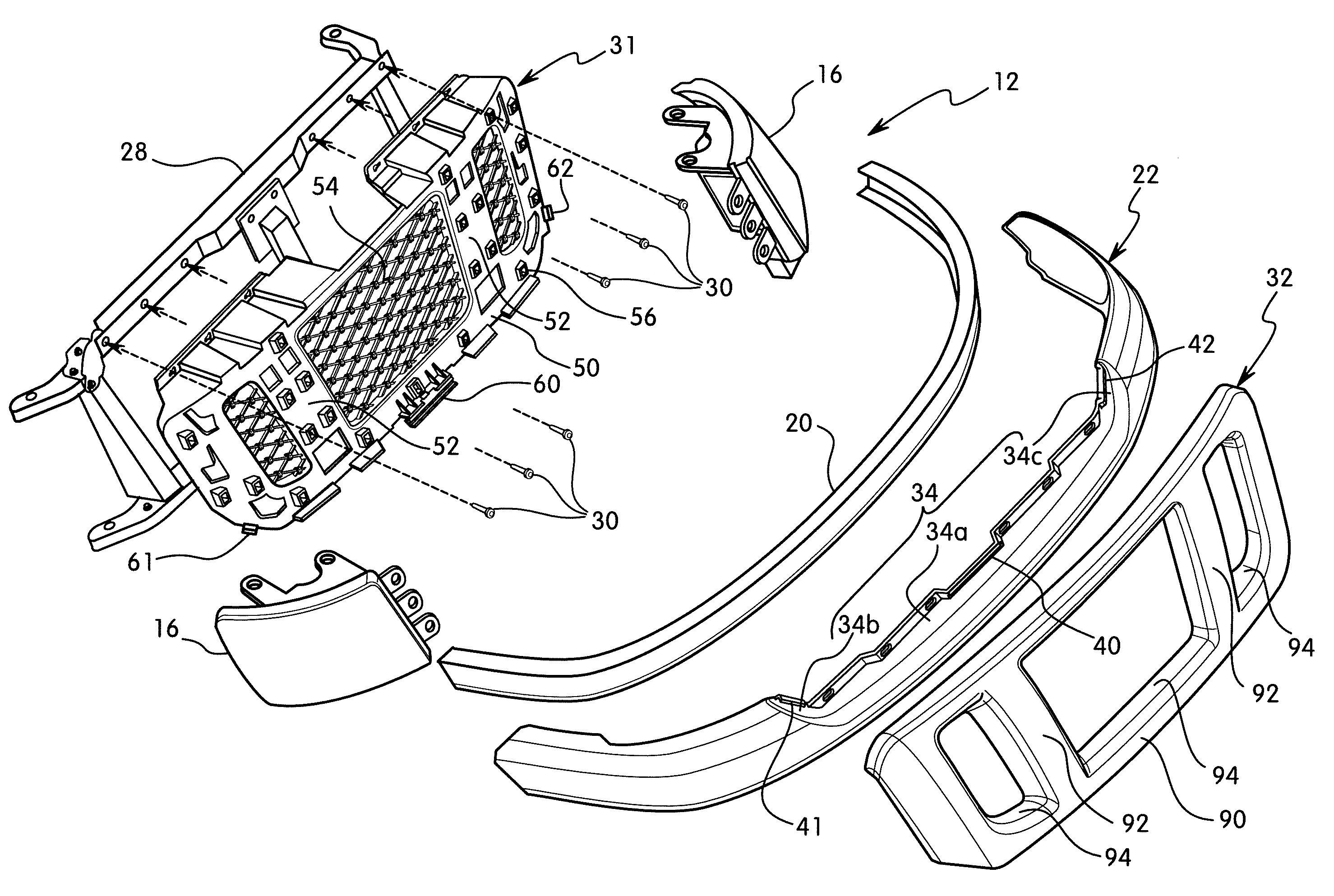

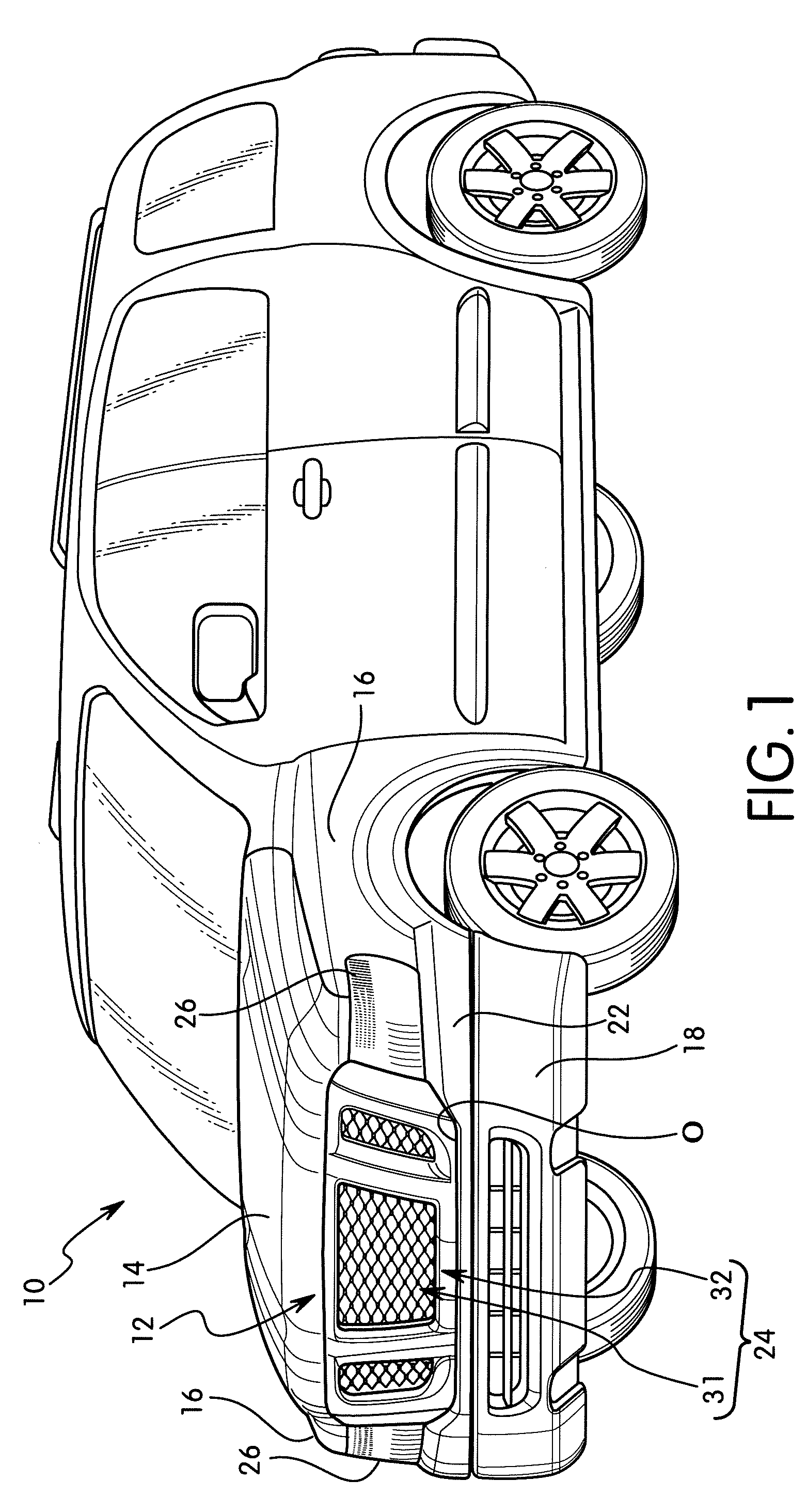

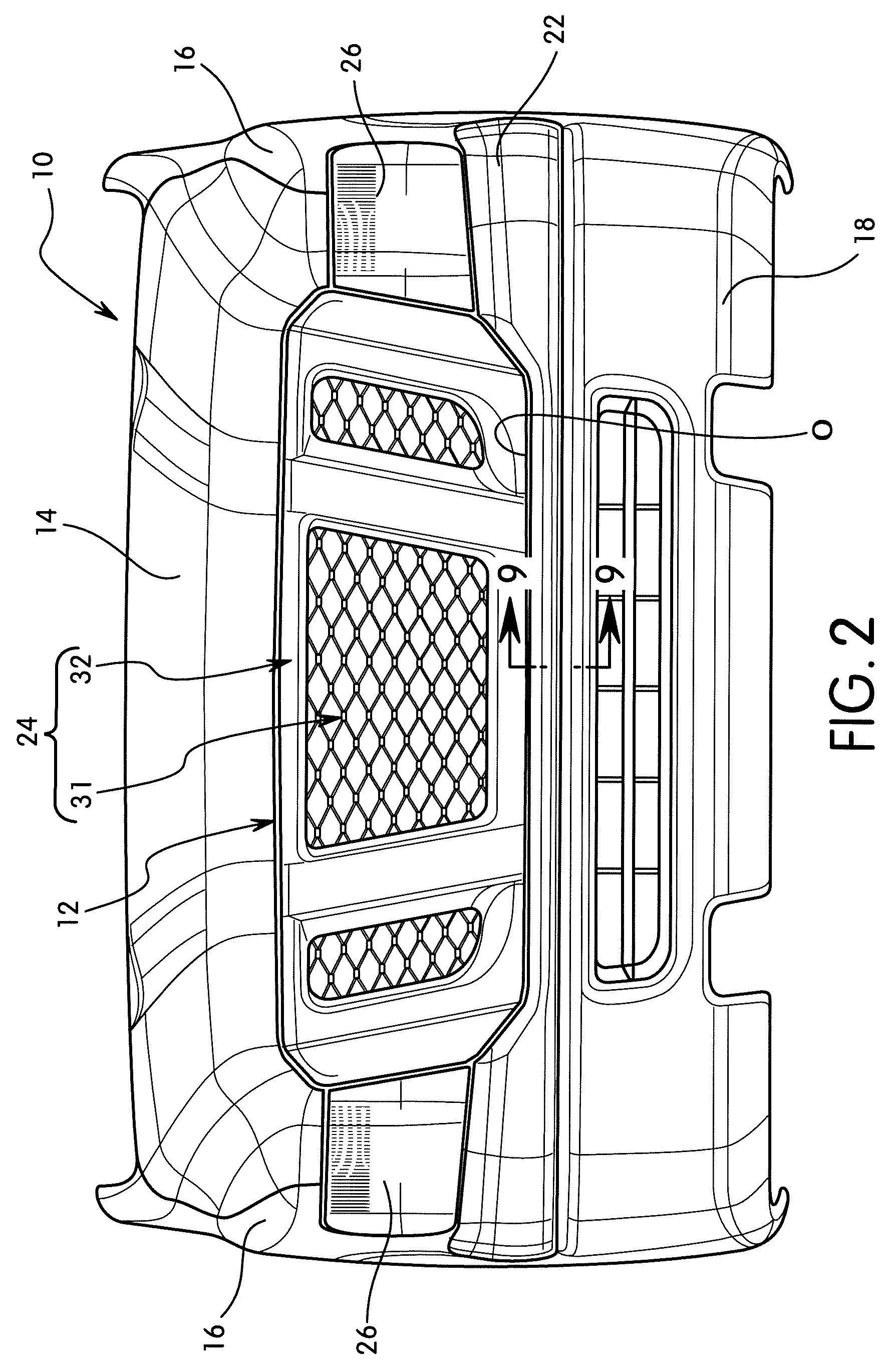

Vehicle end structure

ActiveUS8157303B2Reduce exposureTime consumingVehicle seatsSuperstructure subunitsMechanical engineeringEngineering

A vehicle end structure mainly includes a vehicle bumper fascia and a grille assembly. The vehicle bumper fascia includes a sill portion and a receiving member extending from the sill portion. The receiving member defines a channel with an opening extending in a forward vehicle facing direction. The grille assembly includes inner grille and outer grille members that are coupled together. The inner grille member has a support member formed at a periphery of the inner grille member. The support member is disposed in the channel of the receiving member to limit movement of the inner grille member in a direction normal to the forward vehicle facing direction. The outer grille member is disposed on a forward vehicle facing side of the inner grille member to conceal the support member from view in the first direction.

Owner:NISSAN MOTOR CO LTD

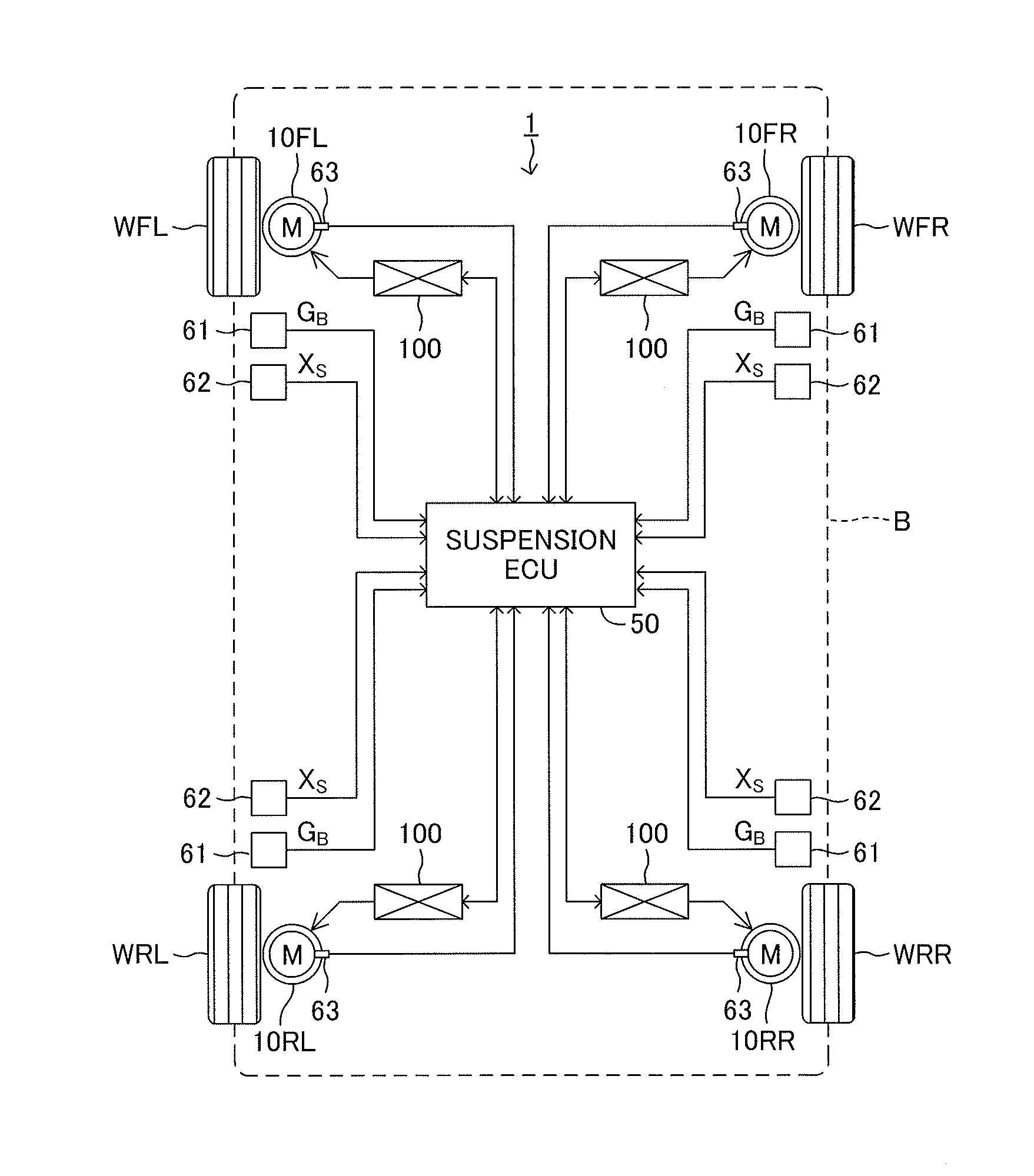

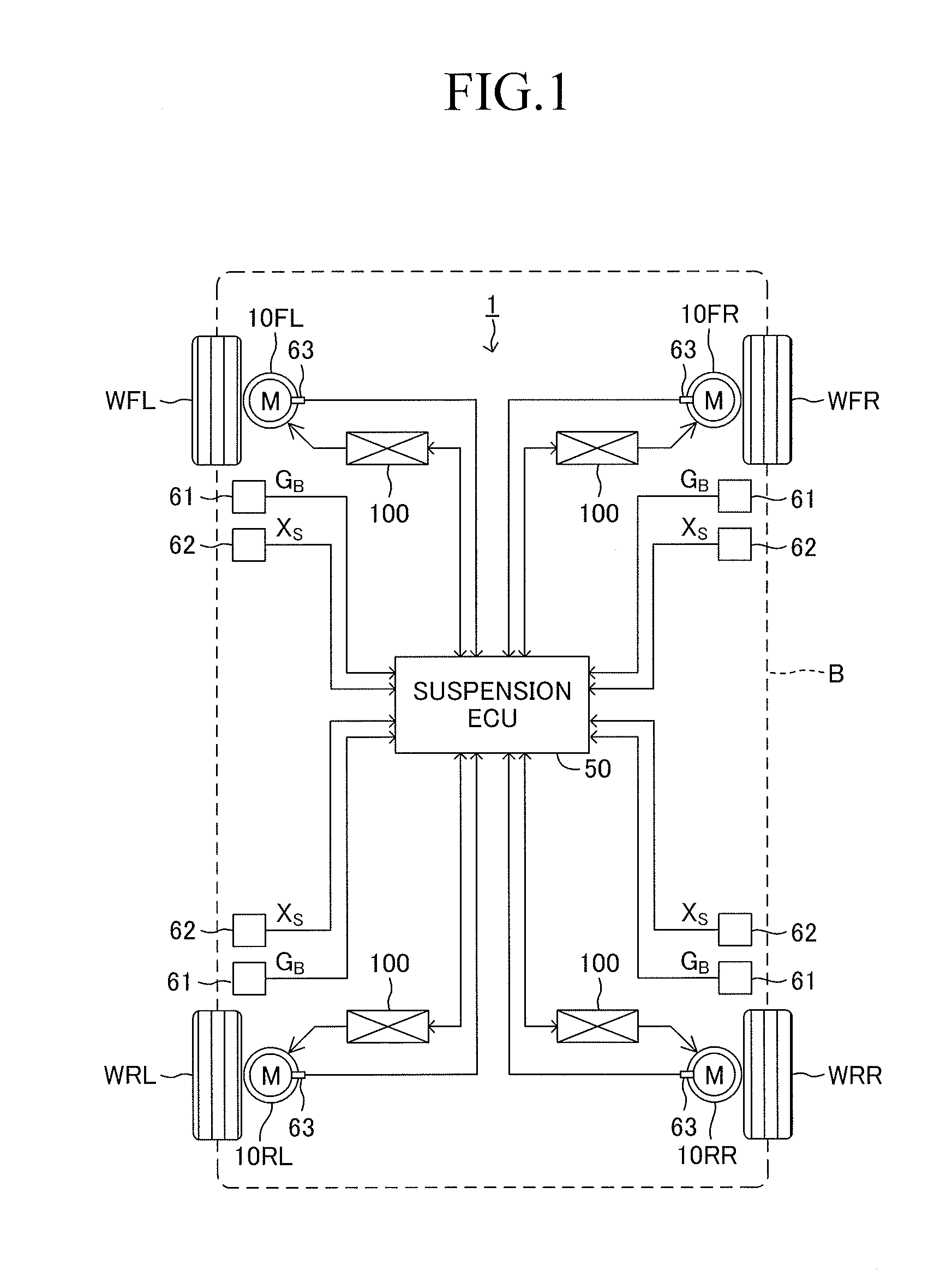

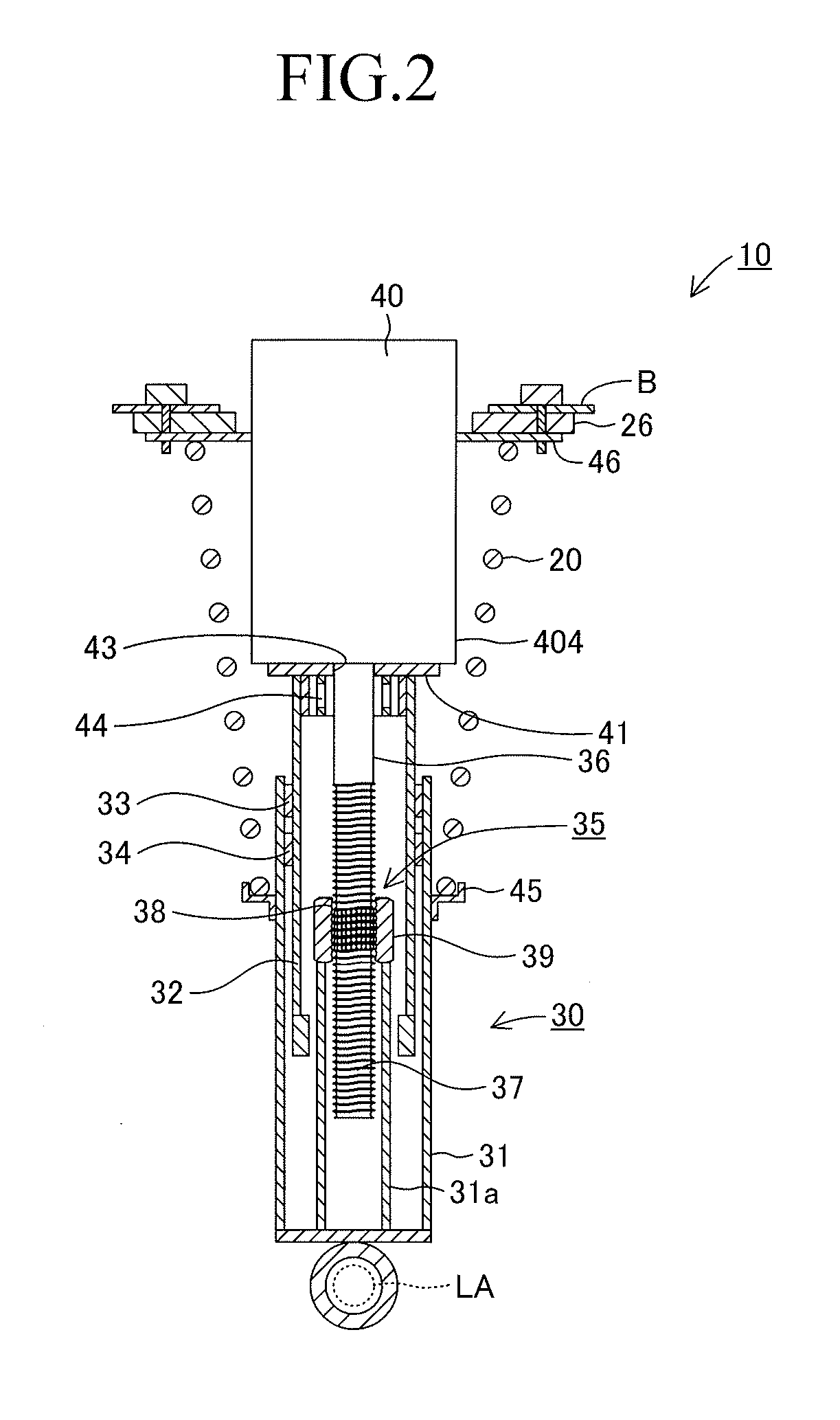

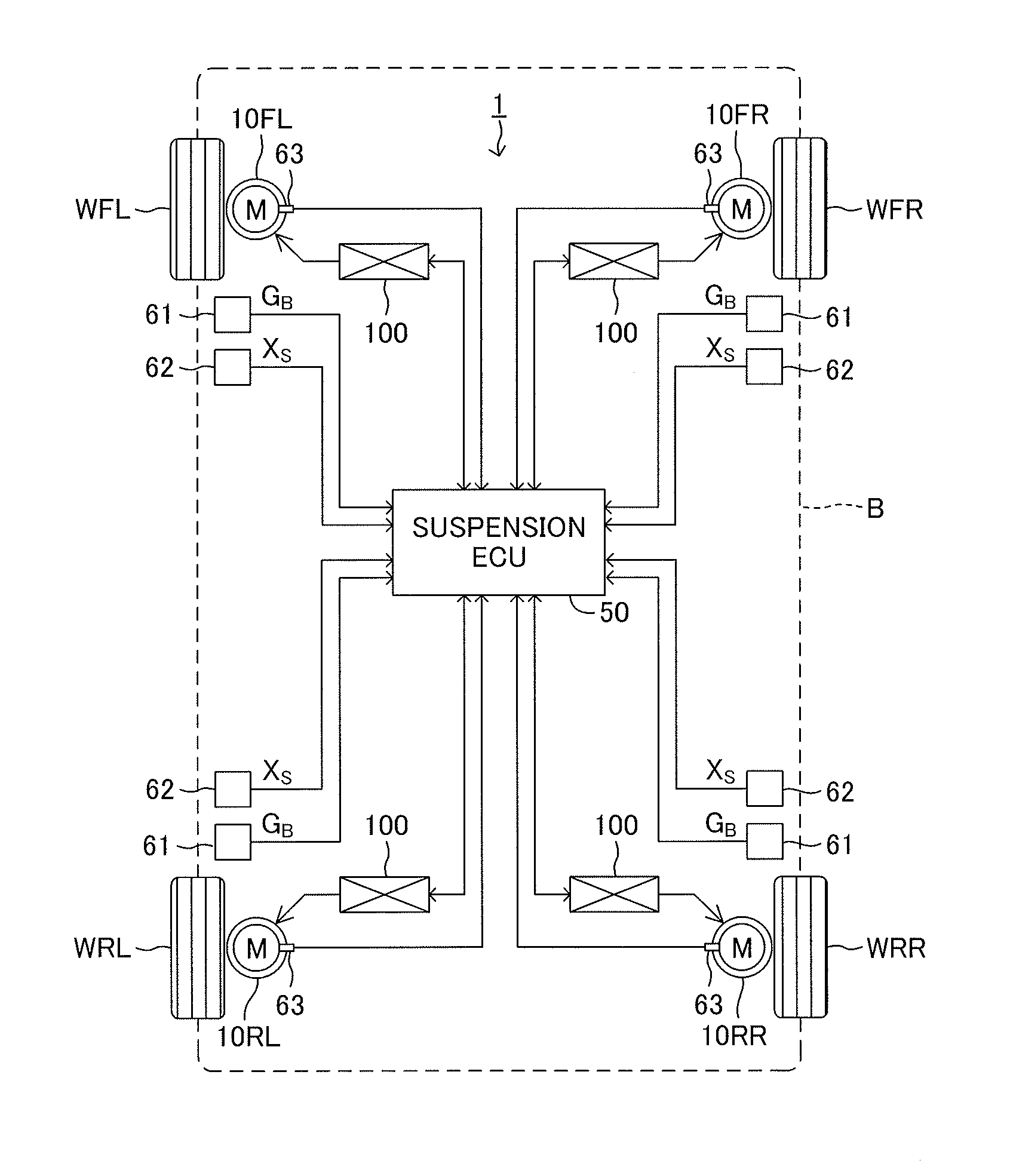

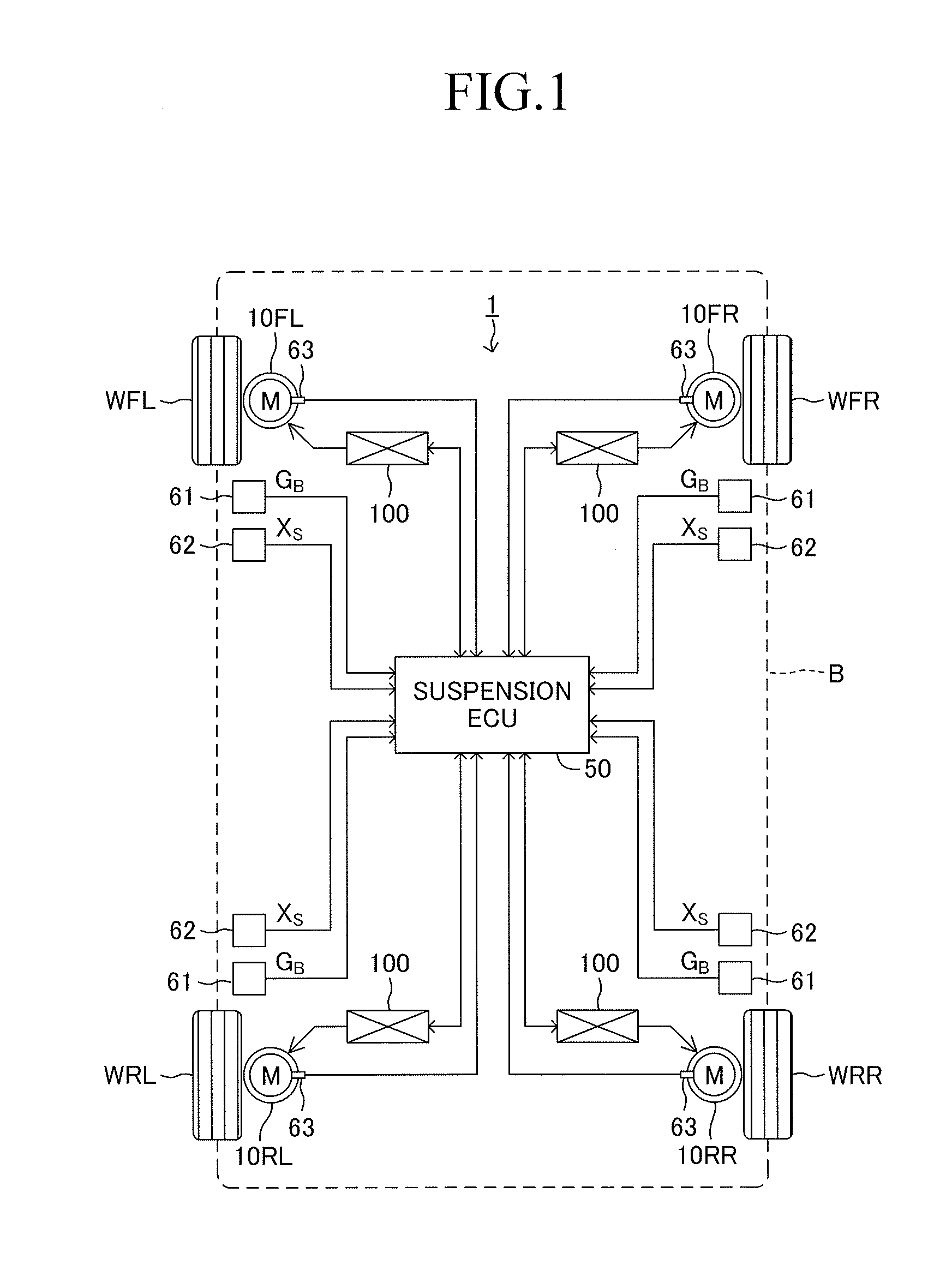

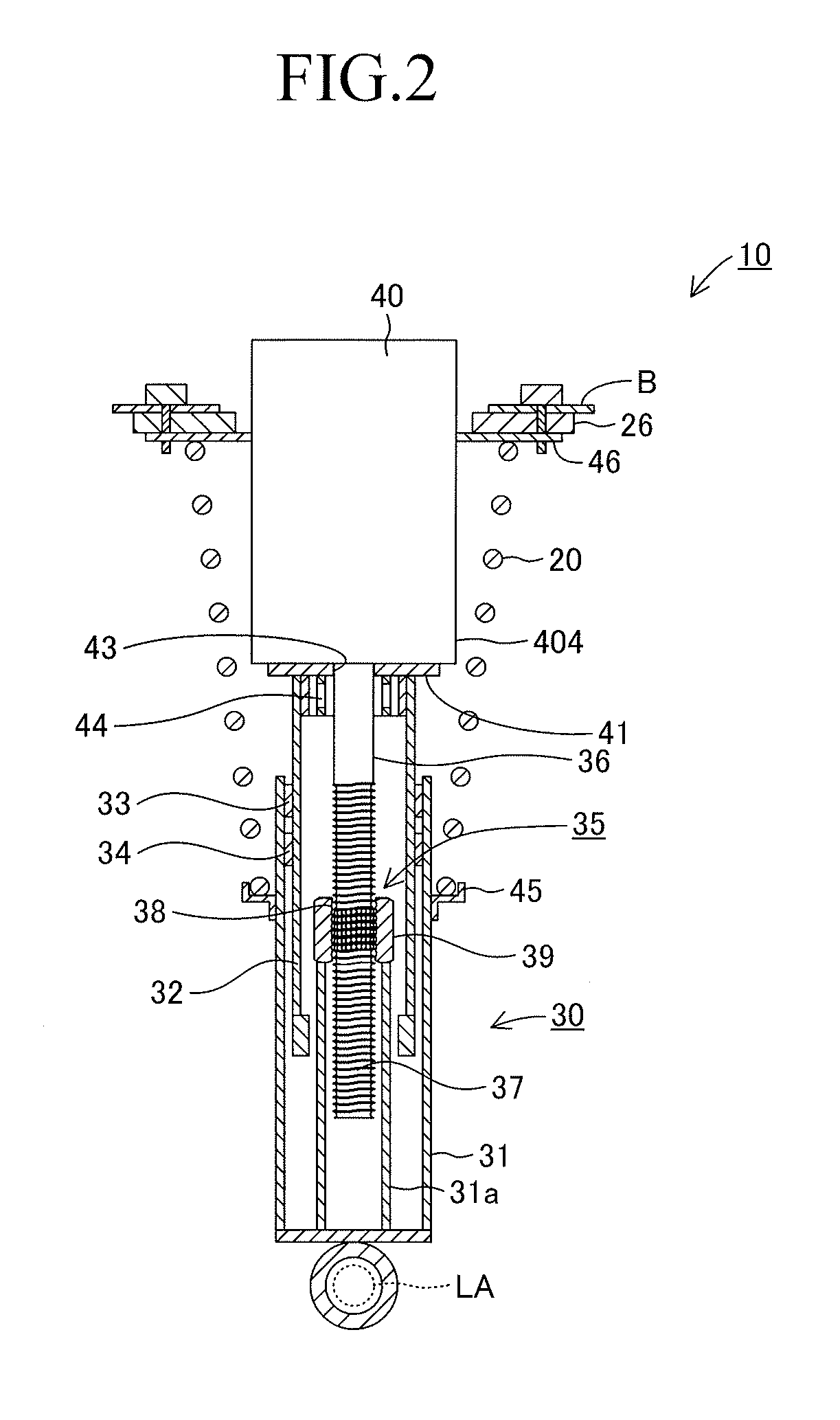

Suspension device

InactiveUS20130060422A1Reducing duty ratioReduce damping forceSpringsVibration dampersElectricityElectric shock

A suspension apparatus 1 includes an electric shock absorber 30 having a motor 40 and a ball screw mechanism 35, an electric circuit 101, an inverting amplification circuit 120, and an inertia compensation capacitor Cp. The electric circuit 101 electrically connects the two electricity supply terminals of the motor 40. The inverting amplification circuit 120 is connected to the electric circuit 101. The inertia compensation capacitor Cp is connected to the output terminal O of the inverting amplification circuit 120. As a result of approaching or separating motion between sprung and unsprung members, not only a generated current but also an inertia corresponding current Im which represents an inertial force of a rotation body, such as the ball screw shaft 36 and the rotor of the motor 40, flows through the motor 40 and the electric circuit 101. A current Ip which is antiphase to the inertia corresponding current Im flows through the inertia compensation capacitor Cp. This antiphase current Ip cancels out the inertia corresponding current Im.

Owner:TOYOTA JIDOSHA KK

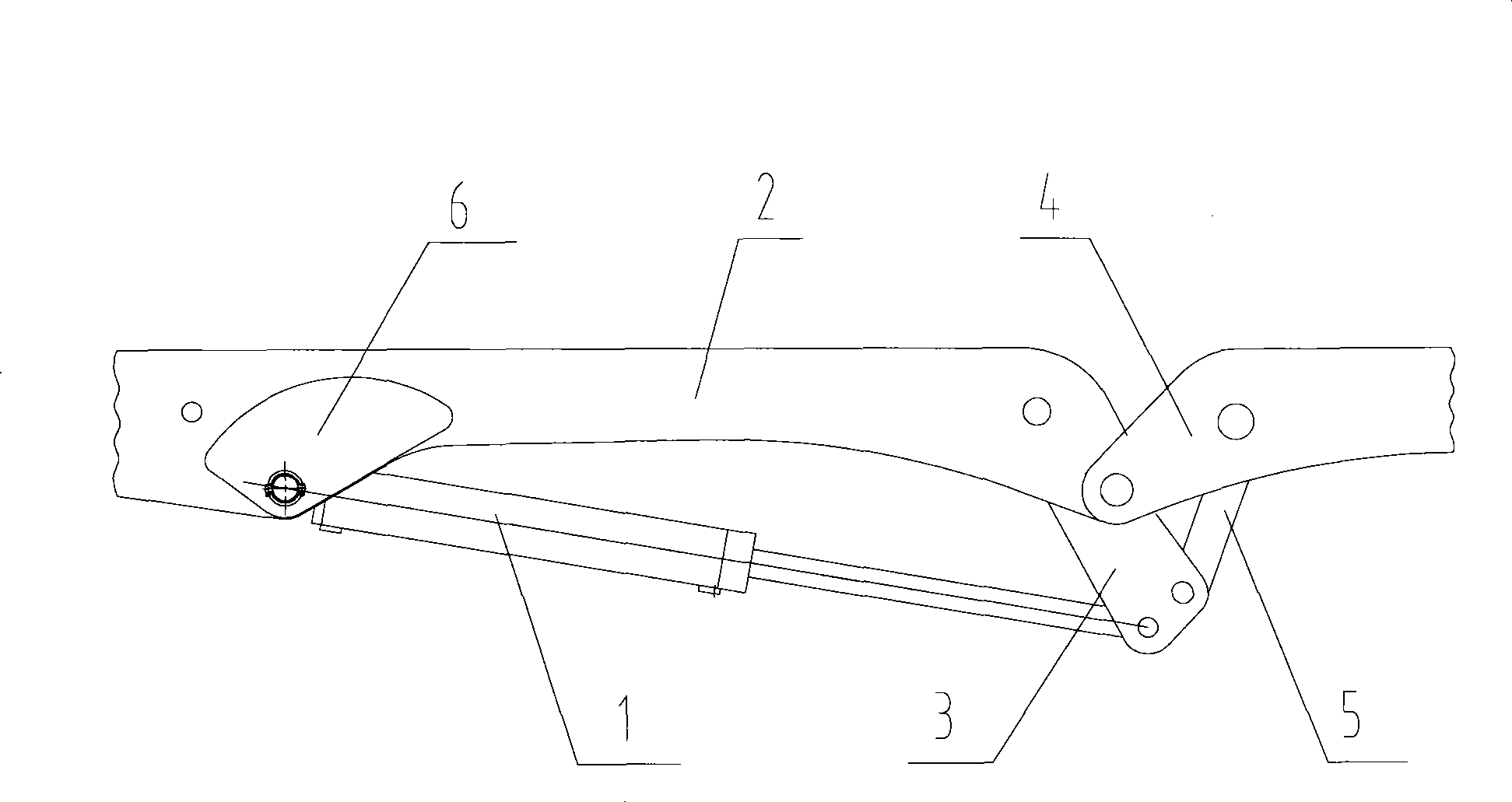

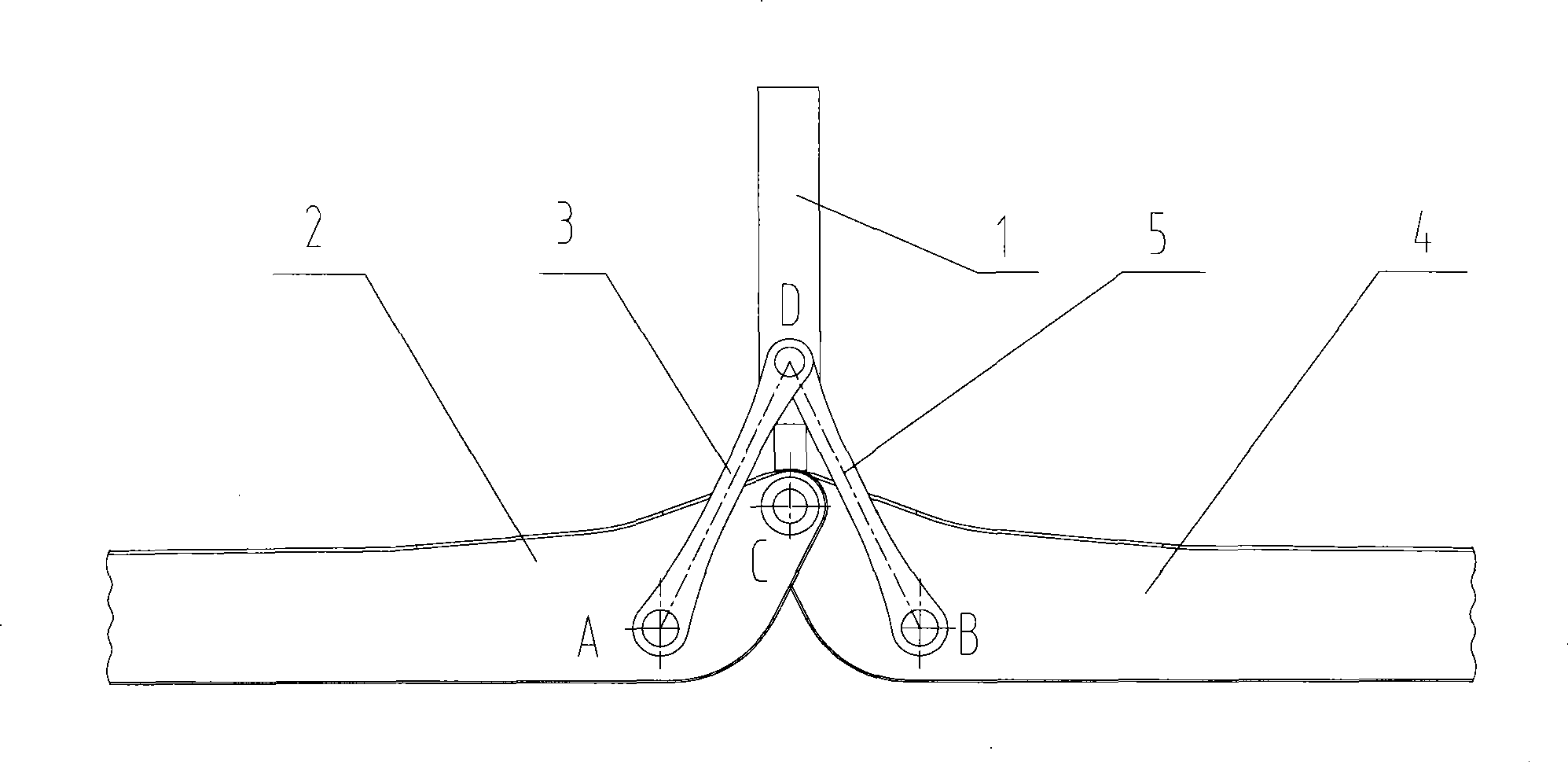

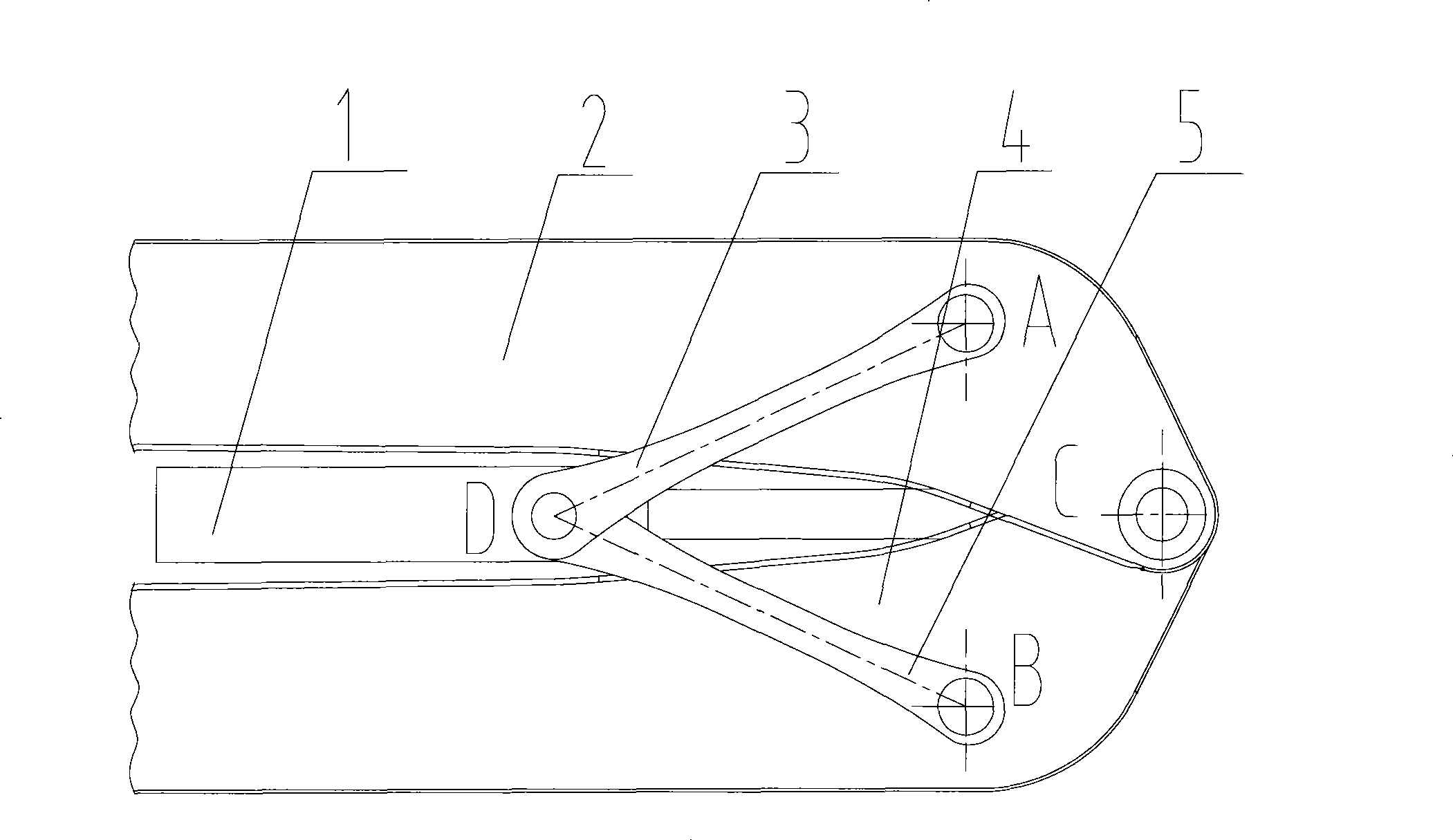

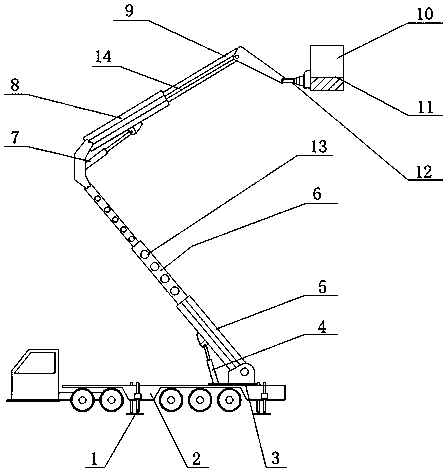

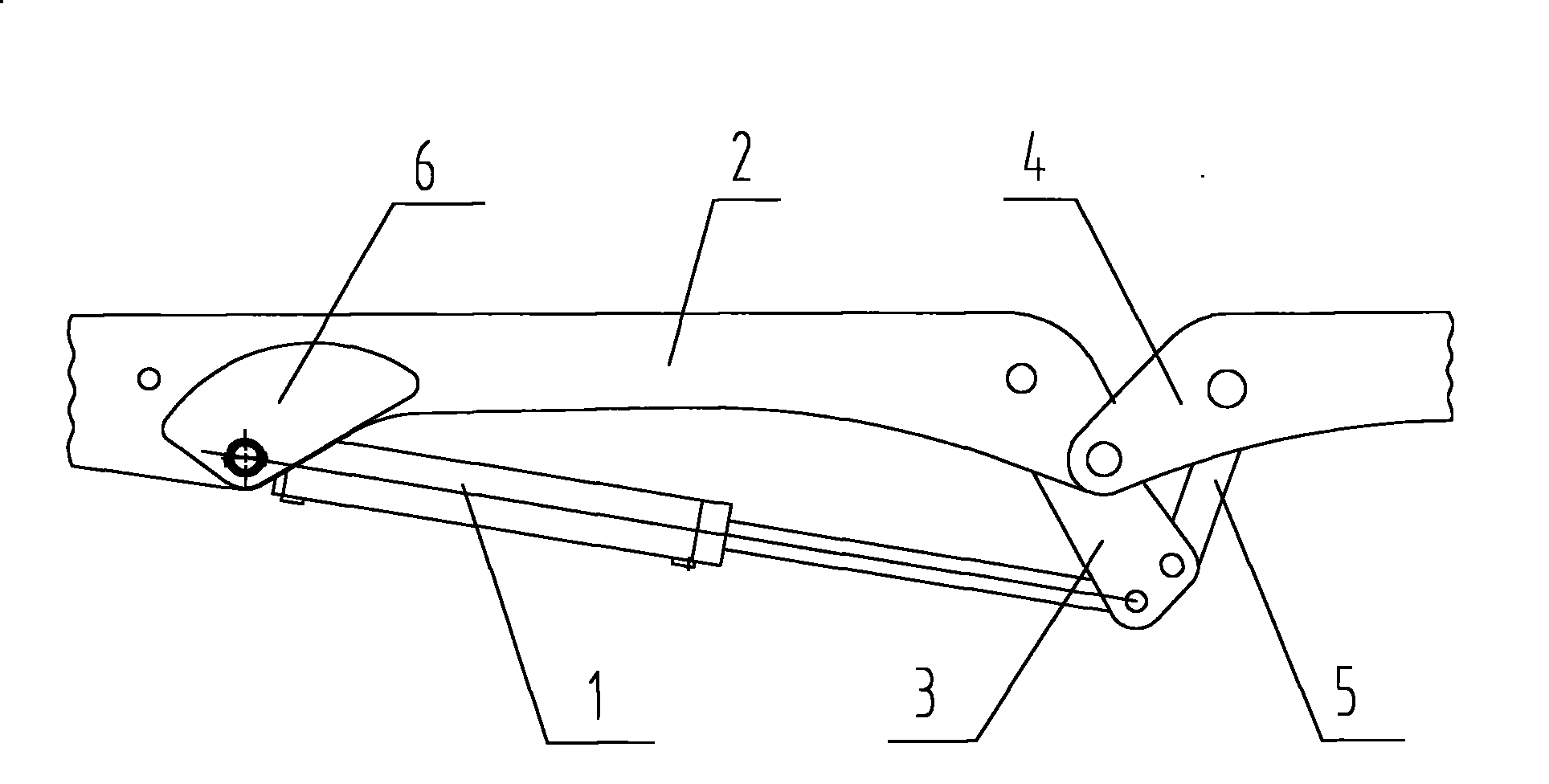

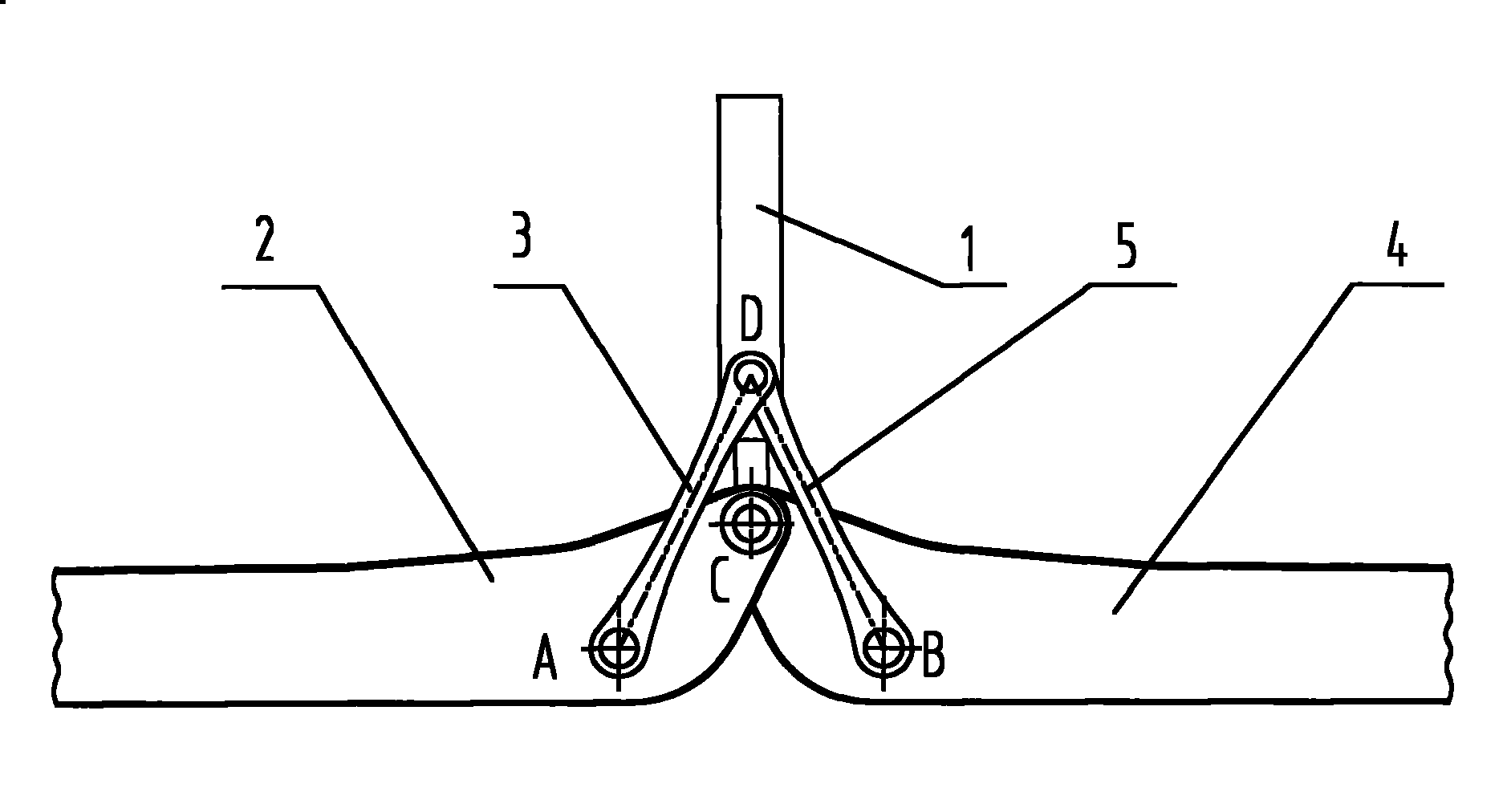

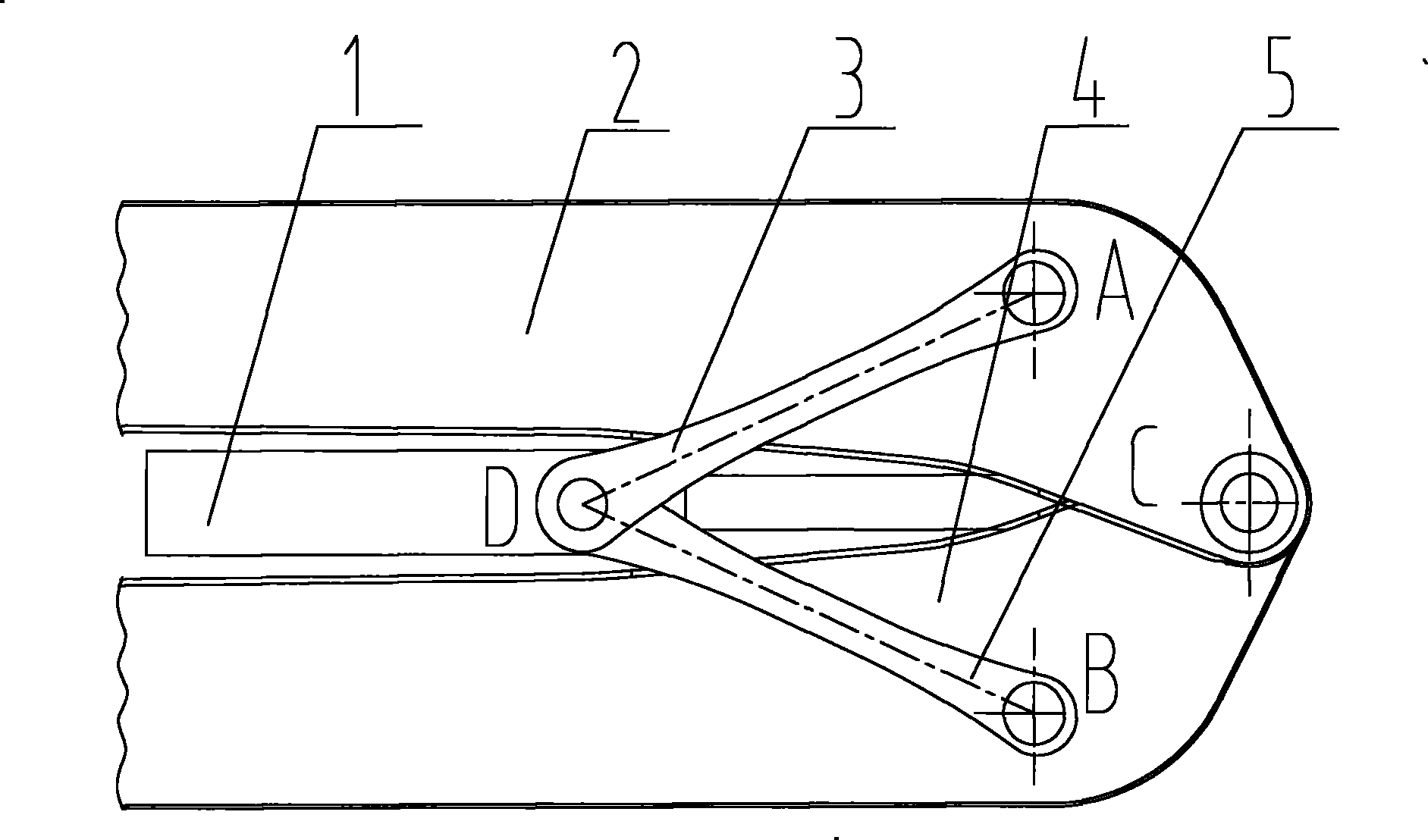

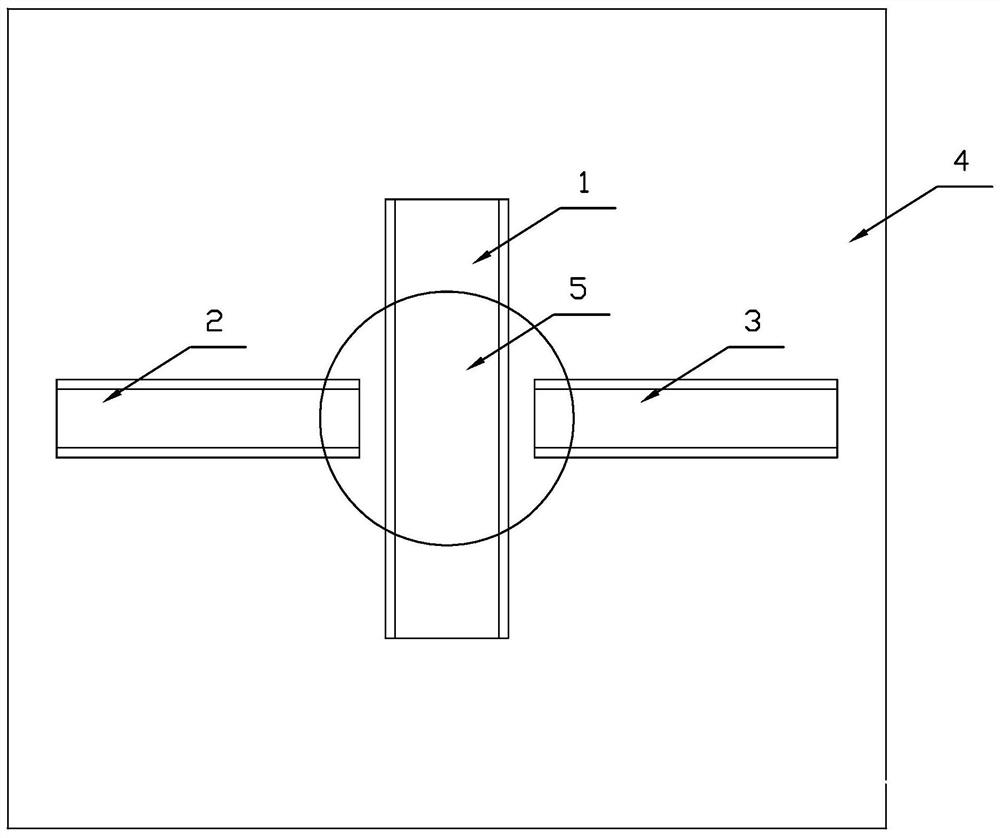

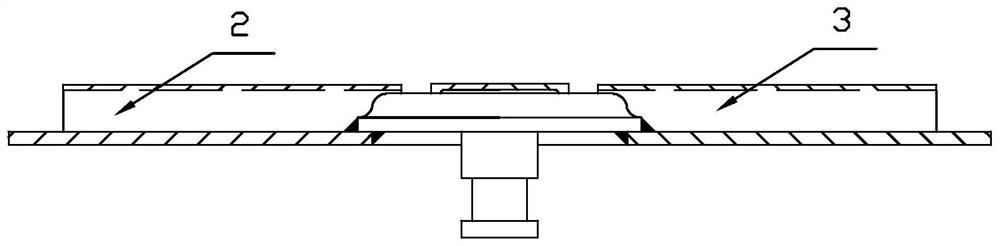

Arm support link mechanism, folding type arm support and concrete pump vehicle

ActiveCN101435267ASimple structural designSimple structureBuilding material handlingEngineeringConcrete pump

The invention discloses an arm frame linkage mechanism, which comprises a first arm frame, a second arm frame, a first linkage, a second linkage, and an oil cylinder, wherein the firs arm frame is hinged with the second arm frame, and one end of the oil cylinder is hinged at the hinge point of the first arm frame and the second arm frame; the head ends of the first linkage, the second linkage are respectively hinged on the first arm frame and the second arm frame; and the tail ends of the first linkage and the second linkage are respectively hinged on the oil cylinder. Because one end of the oil cylinder can be vacant, the arm frames need no oil cylinder seat, and the oil cylinder seat mounting problem can not be considered, the structure design of the arm frames can be greatly simplified; and the linkages adopt simple two hole type, so the structure is simple, and the weight is lighter. For the oil cylinder seat is omitted, not only the latent fault initiated by the tearing of the oil cylinder seat is avoided and the equipment fault rate is reduced, but also the whole vehicle weight of the equipment can be reduced. On the base, the invention also discloses a foldable arm frame and a concrete pump truck.

Owner:SANY AUTOMOBILE MFG CO LTD

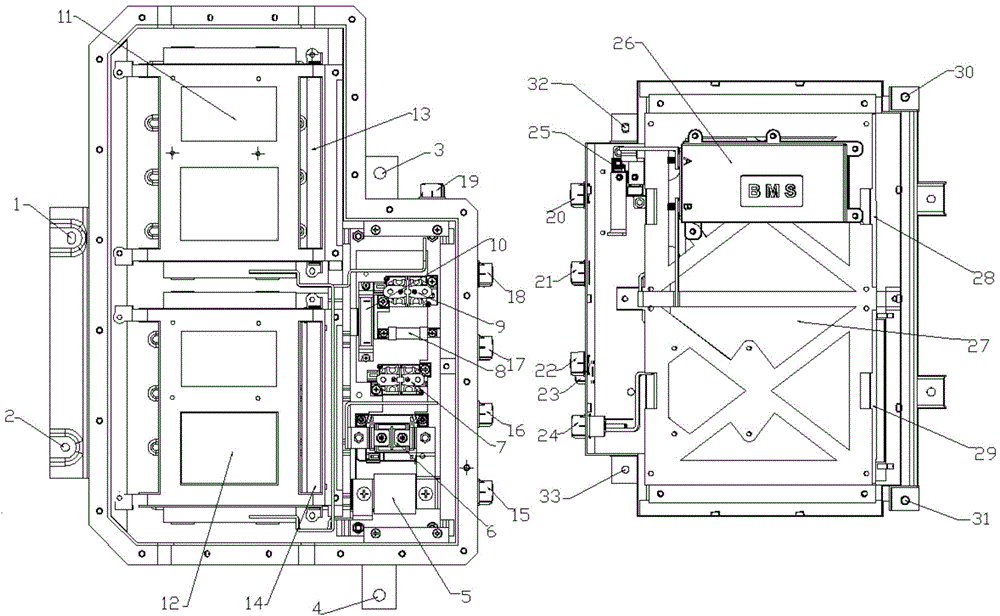

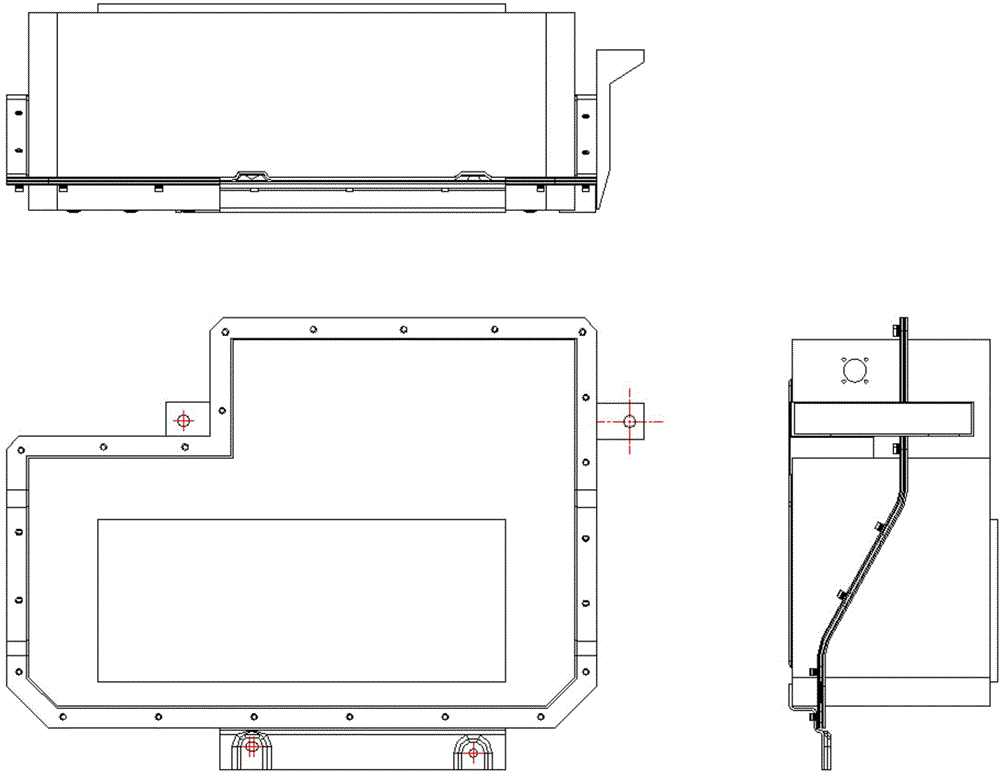

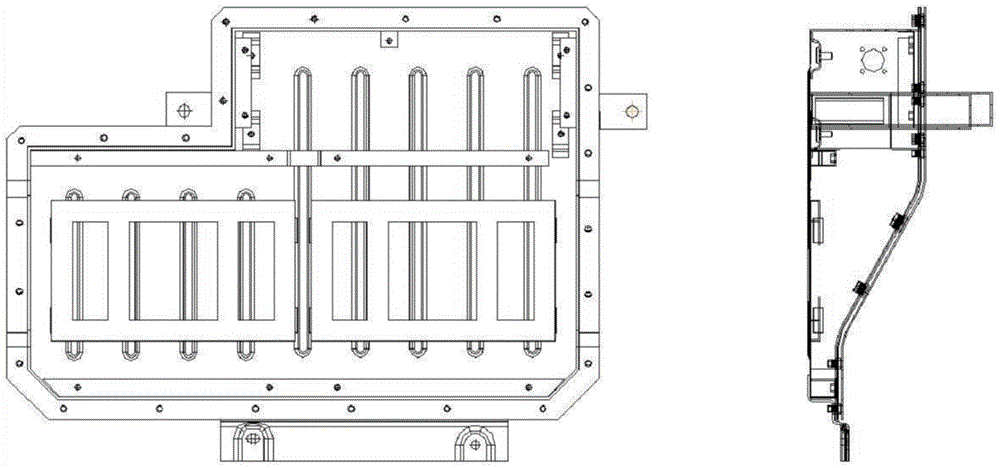

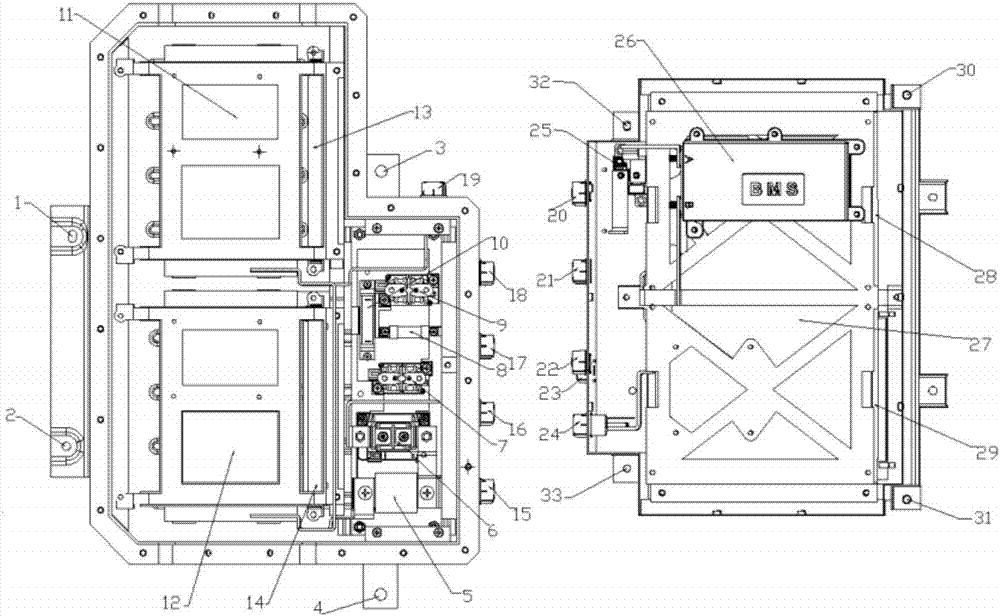

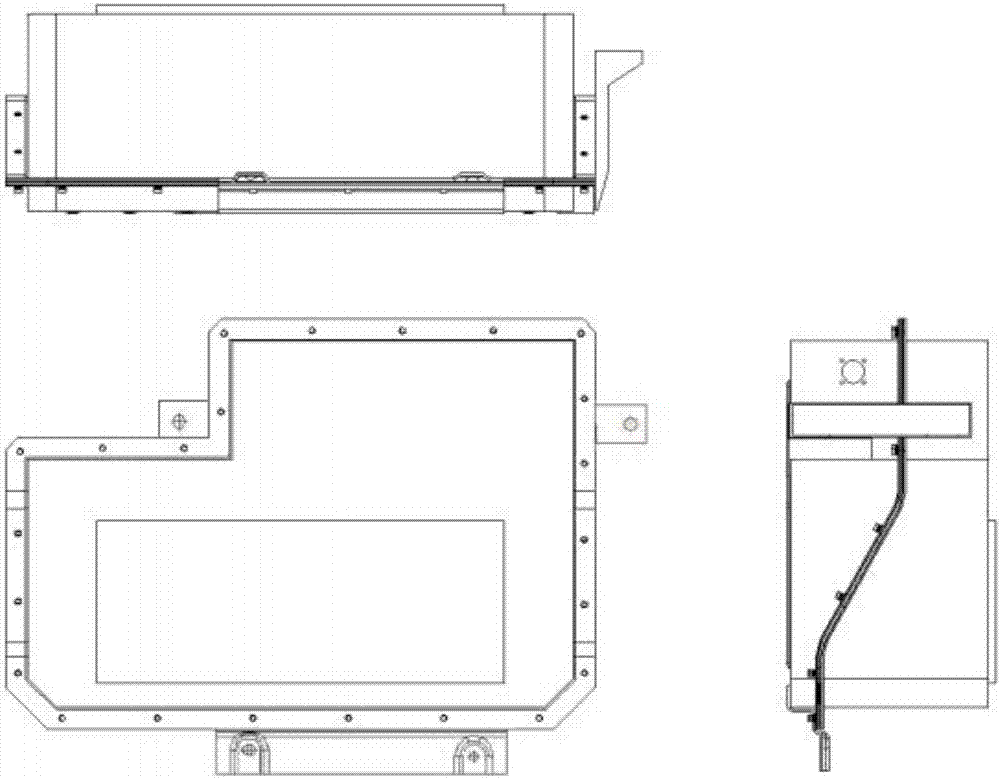

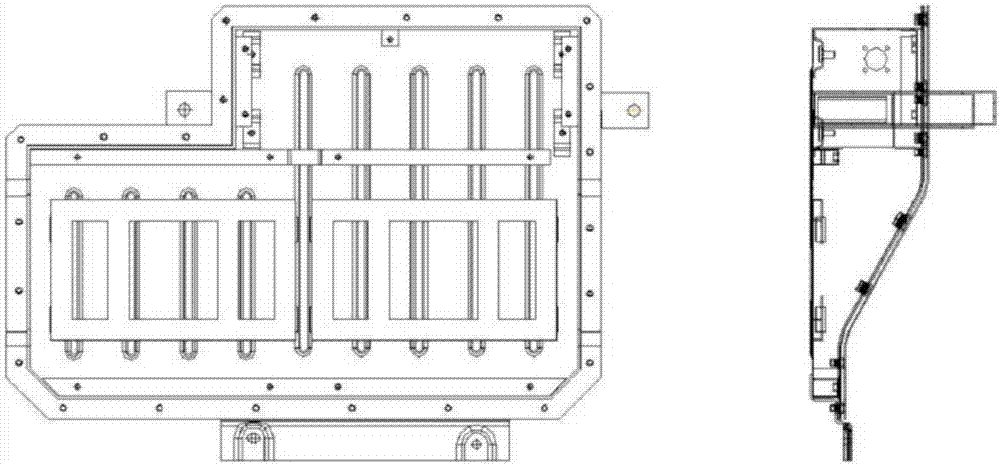

Lithium battery system capable of replacing lead-acid electric vehicle battery system and manufacturing method thereof

ActiveCN104868198AReduce usageReduce the risk of contaminationSecondary cellsCell component detailsElectrical batteryAutomotive battery

The invention relates to a lithium battery system capable of replacing a lead-acid electric vehicle battery system and a manufacturing method thereof. The lithium battery system comprises a battery pack shell, a battery module, a support, a battery management system (BMS) and electric parts, wherein the battery pack shell comprises an upper shell and a lower shell, and the upper shell and the lower shell are connected in a closable manner; the battery module is assembled and formed by connecting lithium batteries in a series-parallel manner, and is fixed to the lower battery pack shell through the support; the BMS is mounted on the support; and the electric parts are mounted at corresponding design positions of the battery pack shell. The manufacturing method comprises the following steps: (1) processing the battery pack shell and the internal support; (2) connecting the lithium batteries in the series-parallel manner to assemble and form the module by using connecting cables and connecting copper bars; (3) putting the module into the lower battery pack shell, and mounting the support to fix the module; (4) mounting the related electric parts at the design positions of the battery shell; (5) mounting the BMS on the support; and (6) closing the upper battery pack shell. Through the replacement scheme, the usage of lead-acid batteries can be reduced, and the risks of environmental pollution are reduced; the lithium batteries are used for replacing the lead-acid batteries, and a low-temperature charging heating system is added, so that the low-temperature discharge capacity and the low-temperature charge performance of the battery system are improved.

Owner:奇瑞新能源汽车股份有限公司

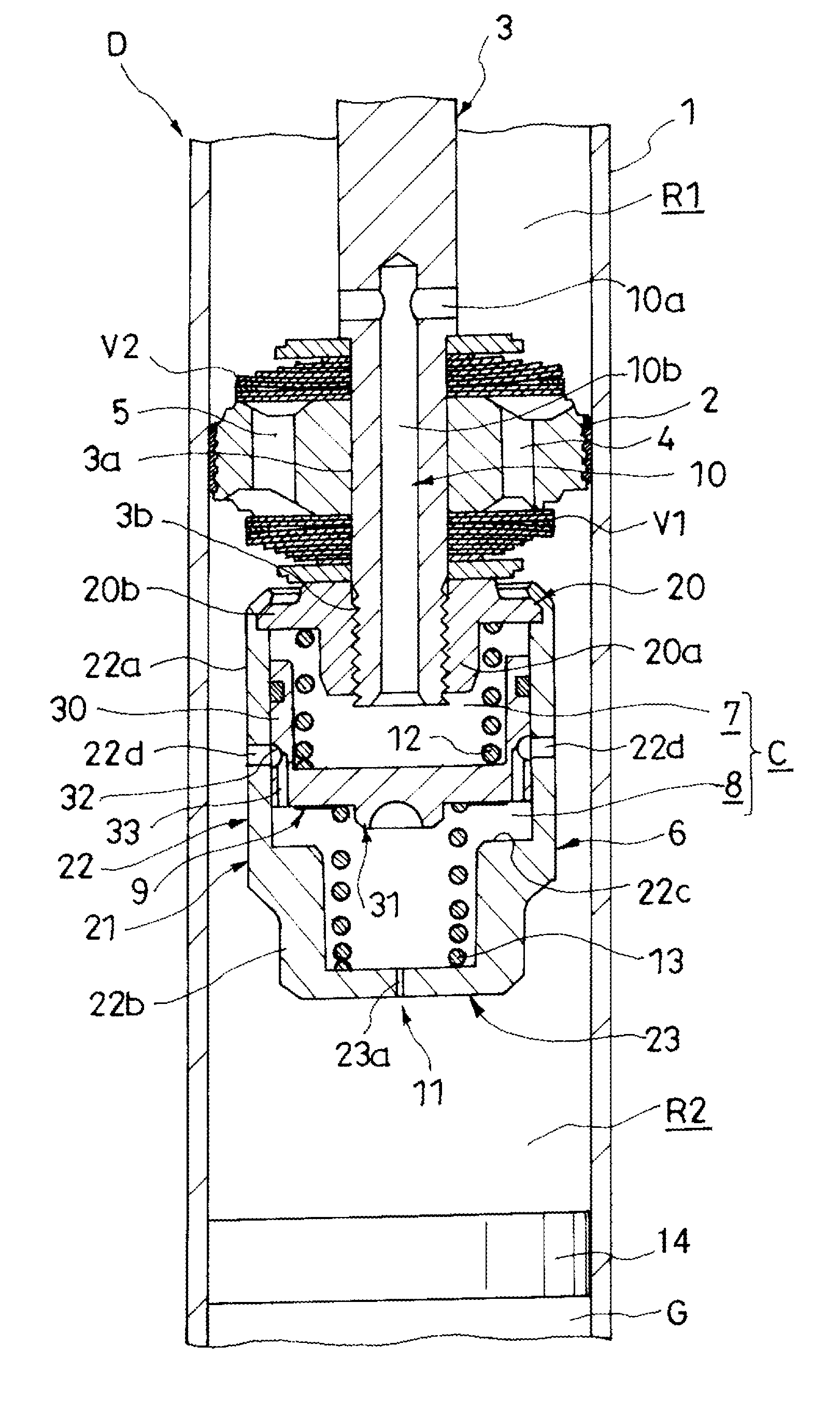

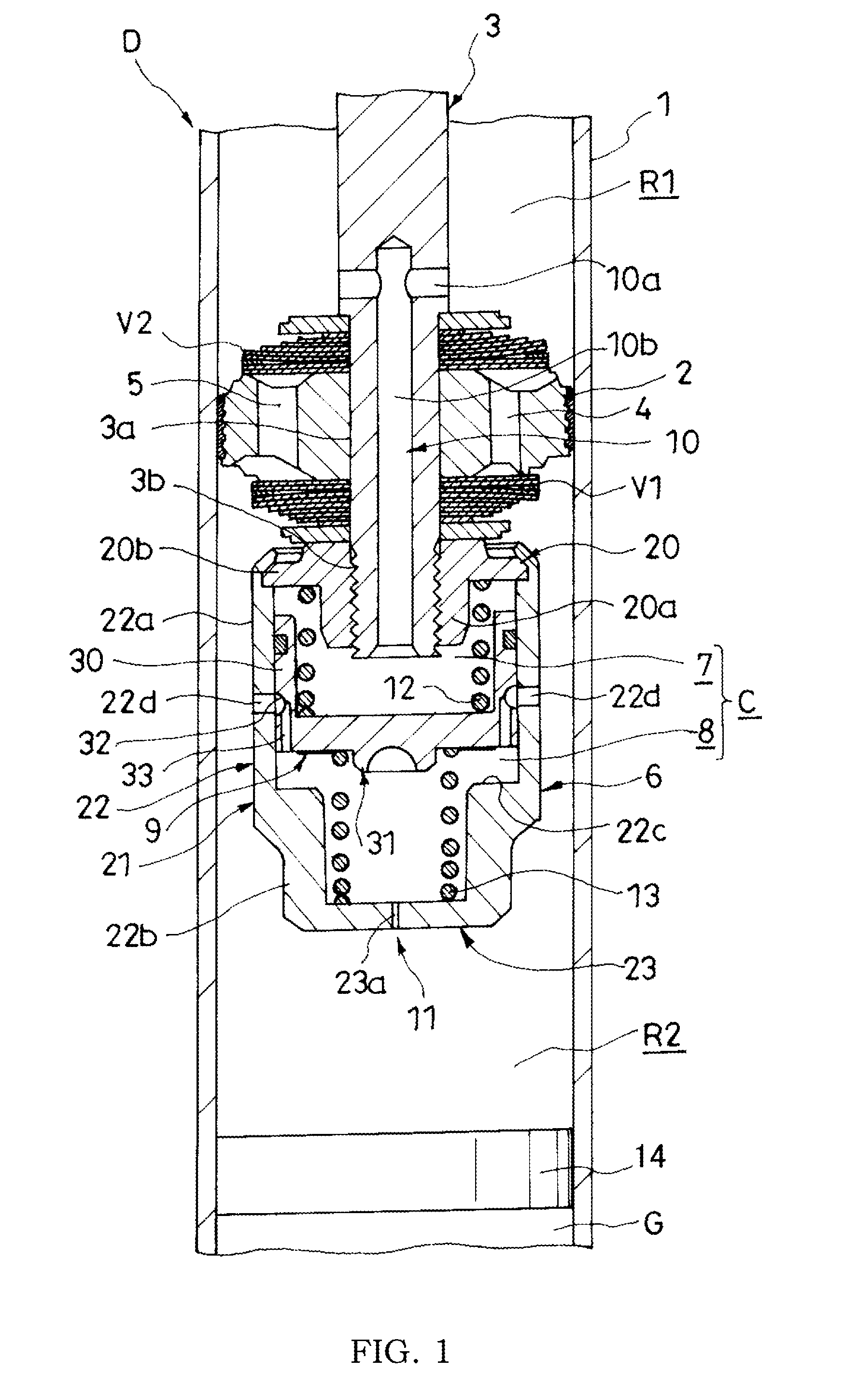

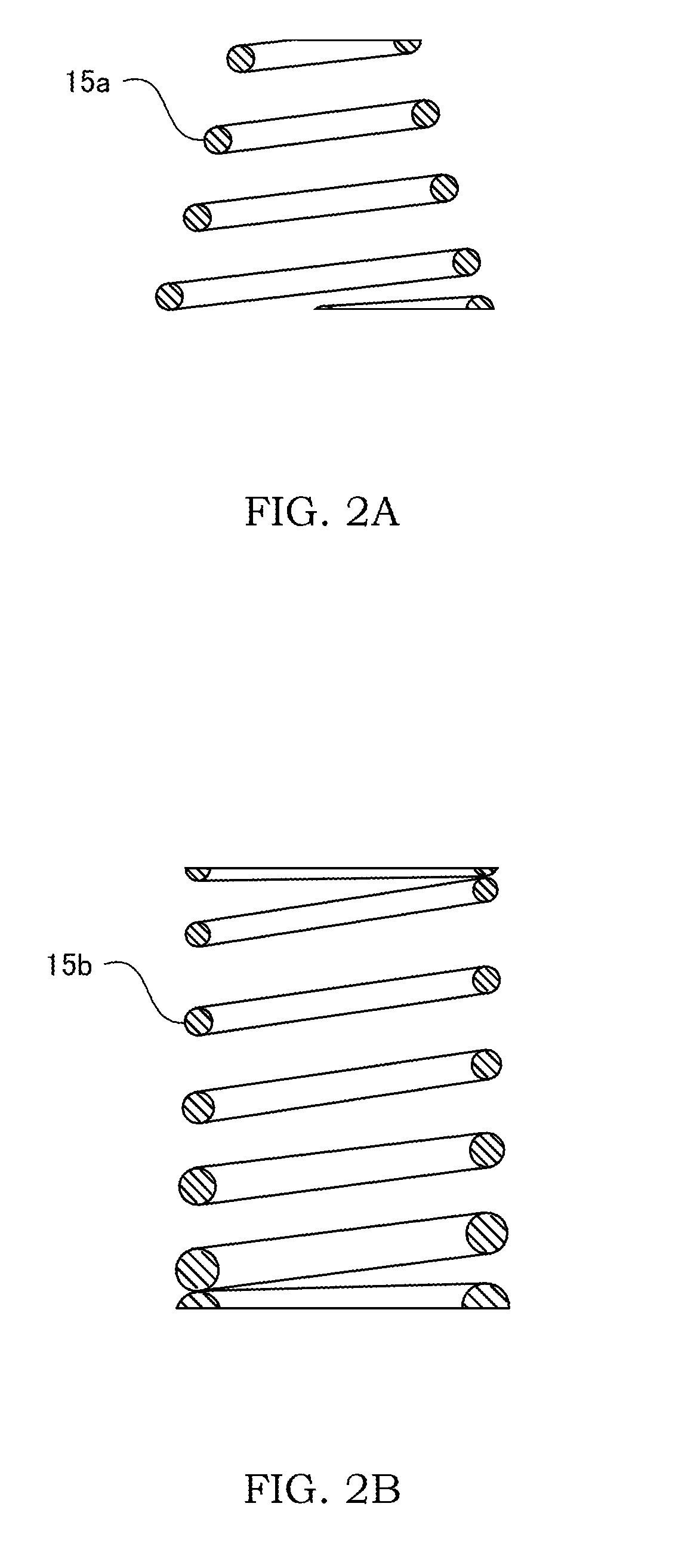

Shock absorber

InactiveUS20160025180A1Reduce vehicle qualitySuppress generationSpringsResilient suspensionsEngineeringPiston

A shock absorber includes expanding-side and contracting-side chambers formed in a cylinder, a housing that forms a pressurizing chamber, a free piston that partitions the pressurizing chamber into an expansive pressurizing chamber communicating with the expanding-side chamber and a contractive pressurizing chamber communicating with the contracting-side chamber, and expanding-side and contracting-side springs that exert biasing forces for suppressing the free piston from being displaced from a neutral position. The contracting-side spring has a non-linear characteristic by which the spring constant increases as it is compressed.

Owner:KYB CORP

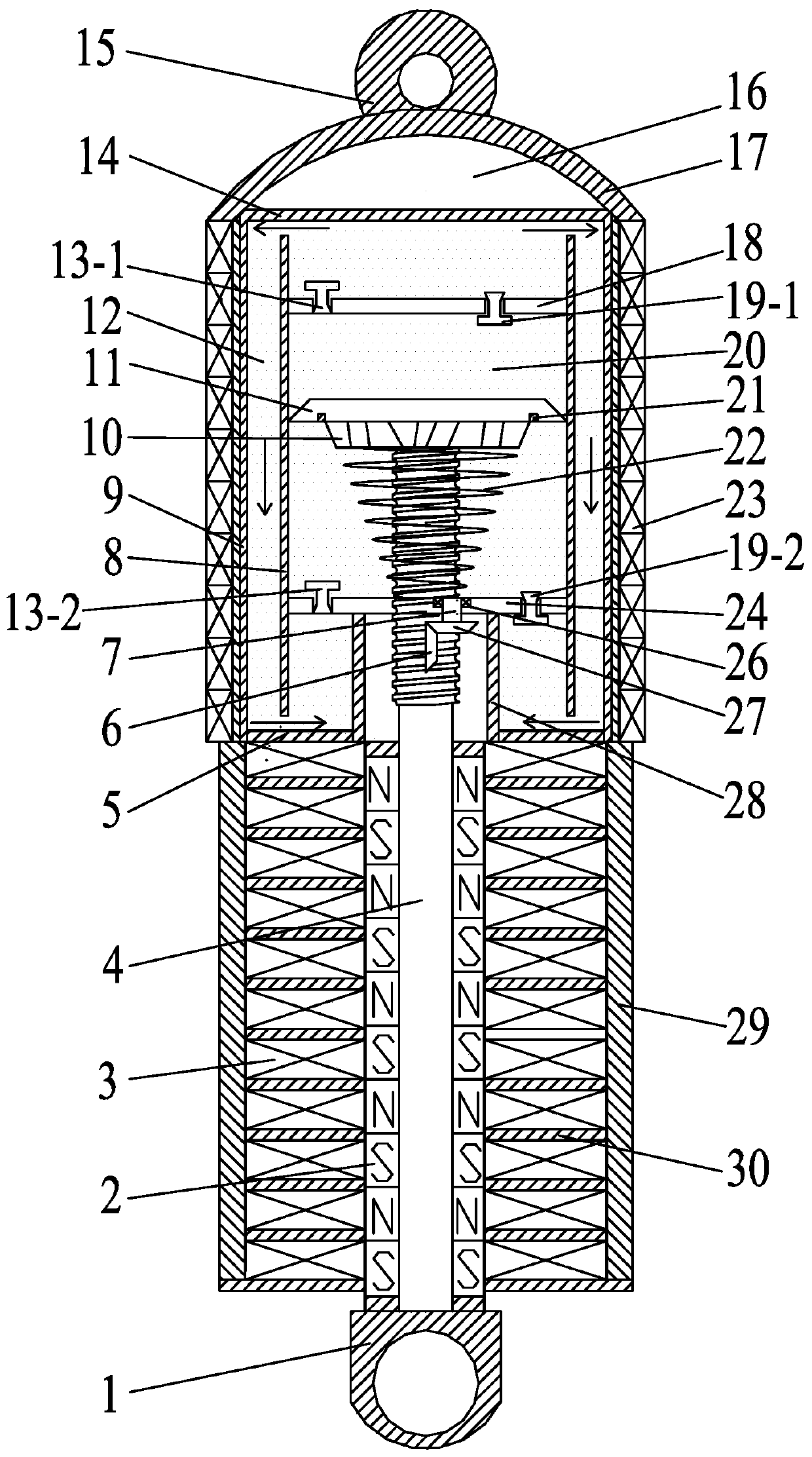

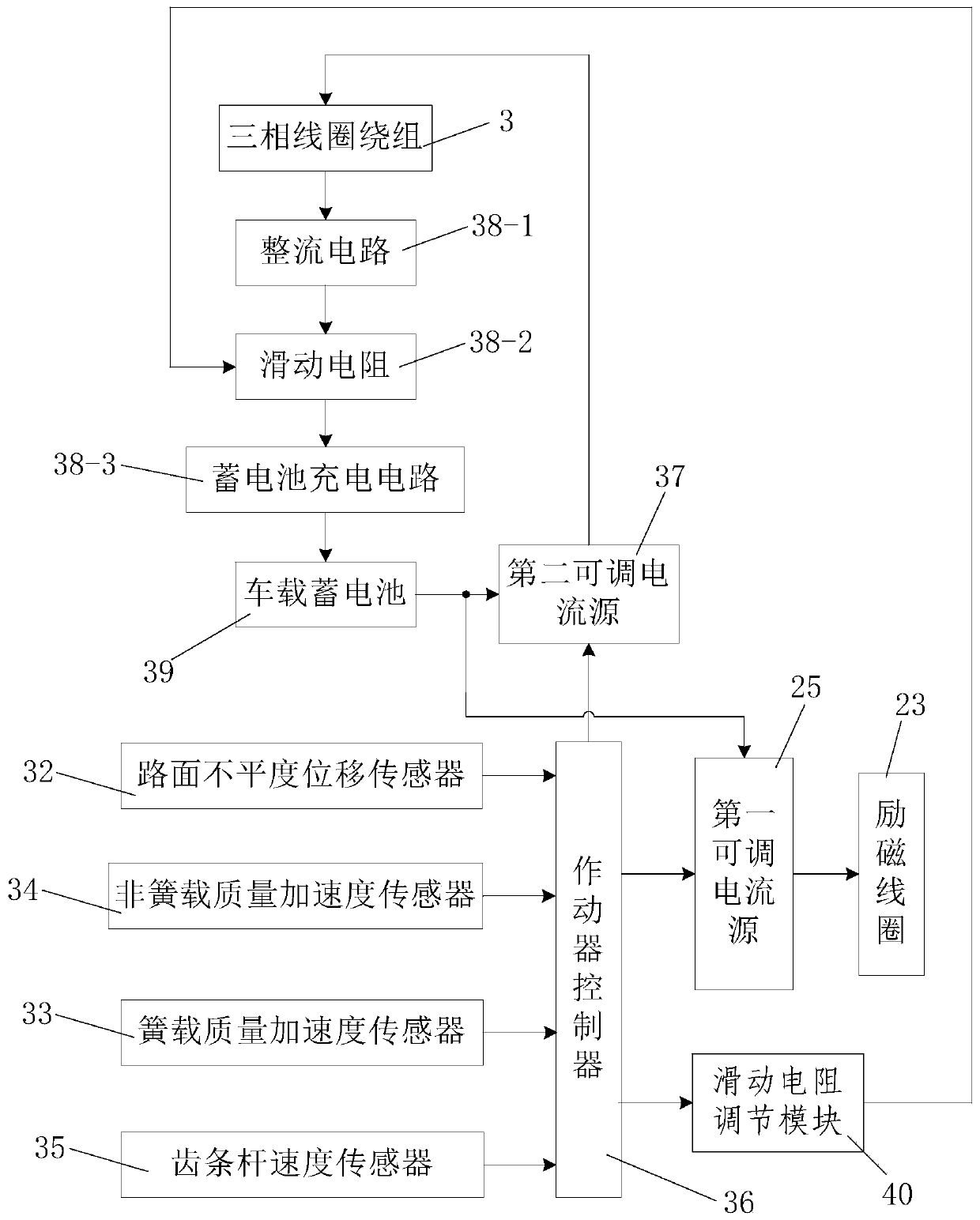

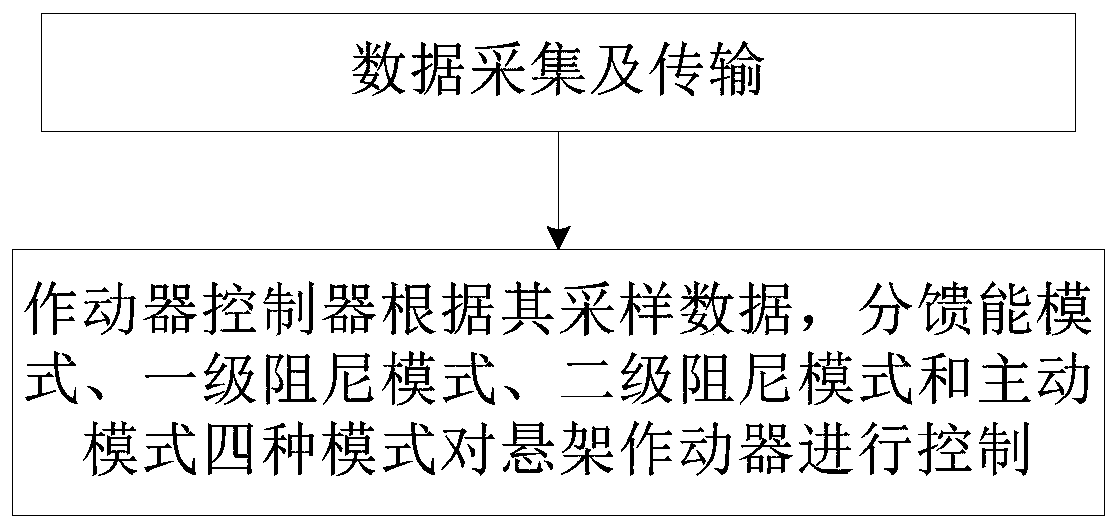

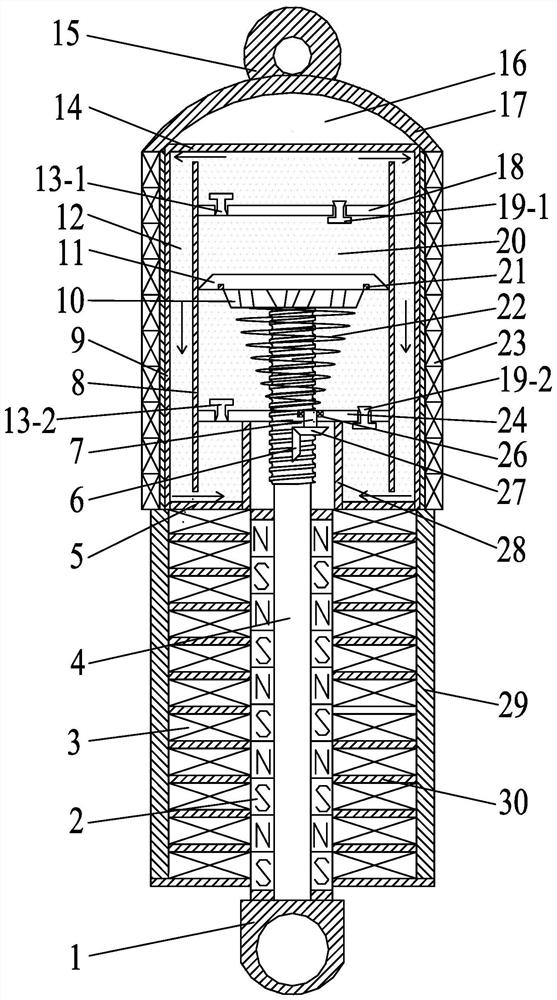

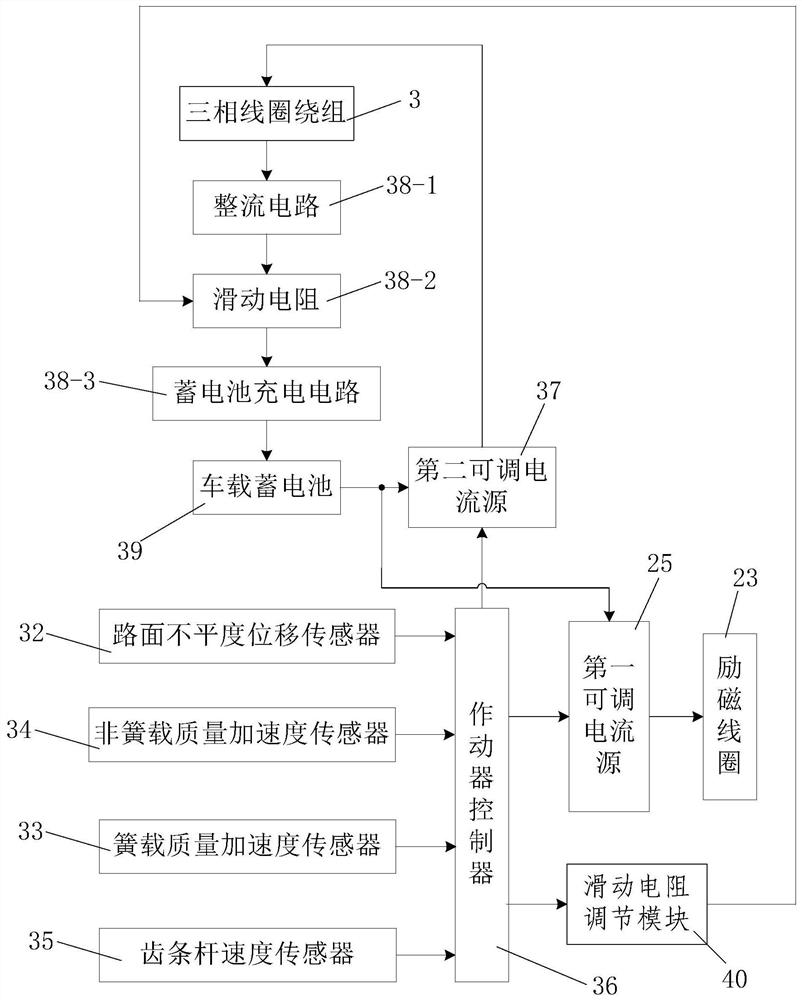

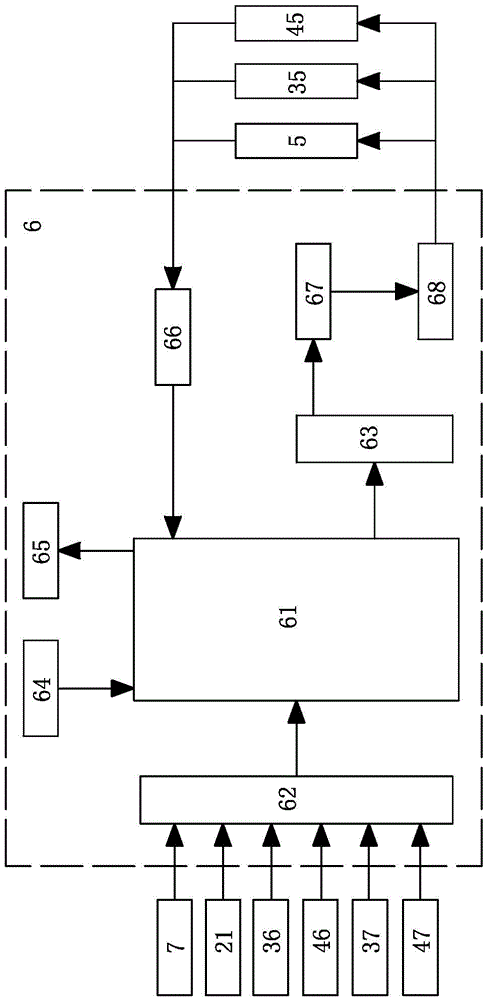

Electromagnetic integrated type energy feedback suspension actuator of electric vehicle and control method of electromagnetic integrated type energy reclaiming suspension actuator of electric vehicle

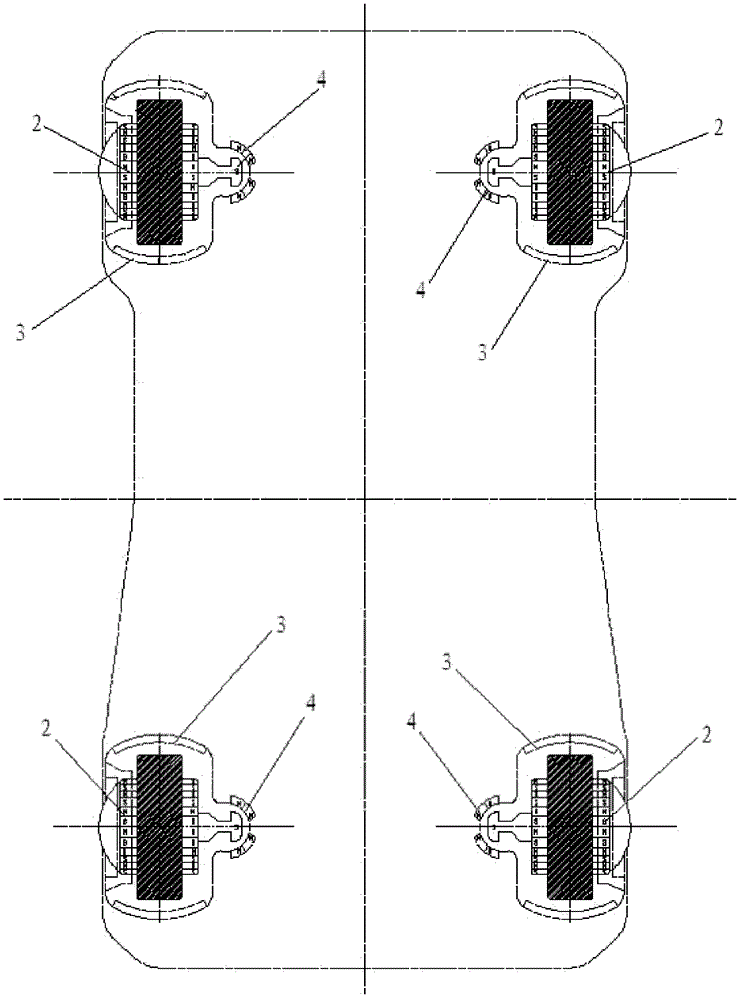

ActiveCN109808437AReasonable designSimple structureResilient suspensionsElectric machineData acquisition

The invention discloses an electromagnetic integrated type energy feedback suspension actuator of an electric vehicle and a control method of the electromagnetic integrated type energy feedback suspension actuator of the electric vehicle. The suspension actuator comprises a magnetorheological damper, a linear motor and an actuator monitoring device, wherein the magnetorheological damper comprisesa cylinder, a magnetorheological fluid, an inner chamber upper partition board and an inner chamber lower partition board, wherein the linear motor comprises a linear motor shell, a secondary part anda primary part; the actuator monitoring device comprises an actuator controller. The control method of the suspension actuator comprises the following steps: 1, data acquisition and transmission; 2,control of the suspension actuator by the actuator controller in an energy feedback mode, a primary damping mode, a secondary damping mode and an active mode according to sample data. The suspension actuator is reasonable in design, multi-mode switching of a suspension system can be realized according to different road conditions of vehicle traveling, energy waste of the electric vehicle is reduced, driving mileage of the electric vehicle can be increased, and the promotion and application values are high.

Owner:XIAN UNIV OF SCI & TECH

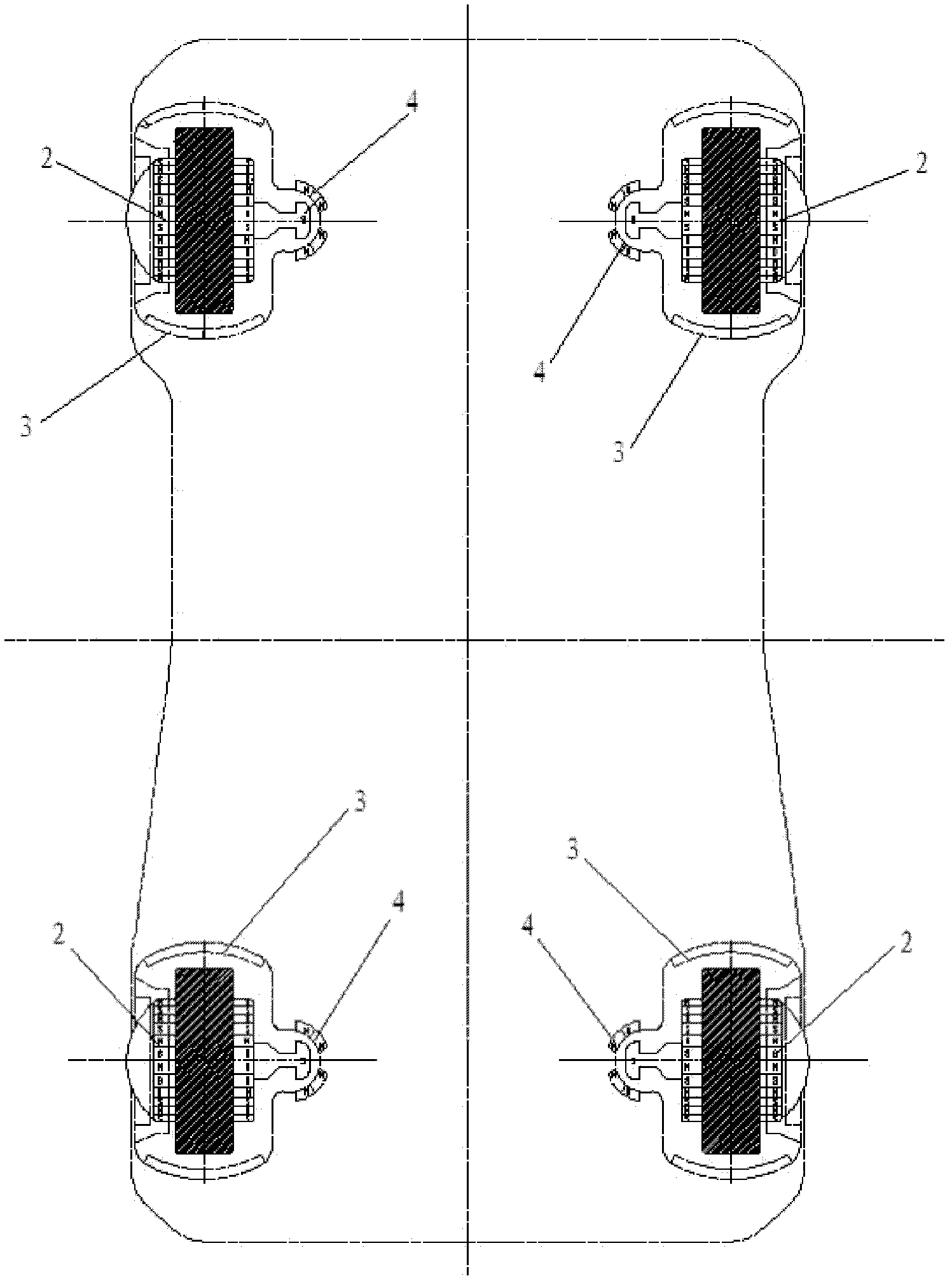

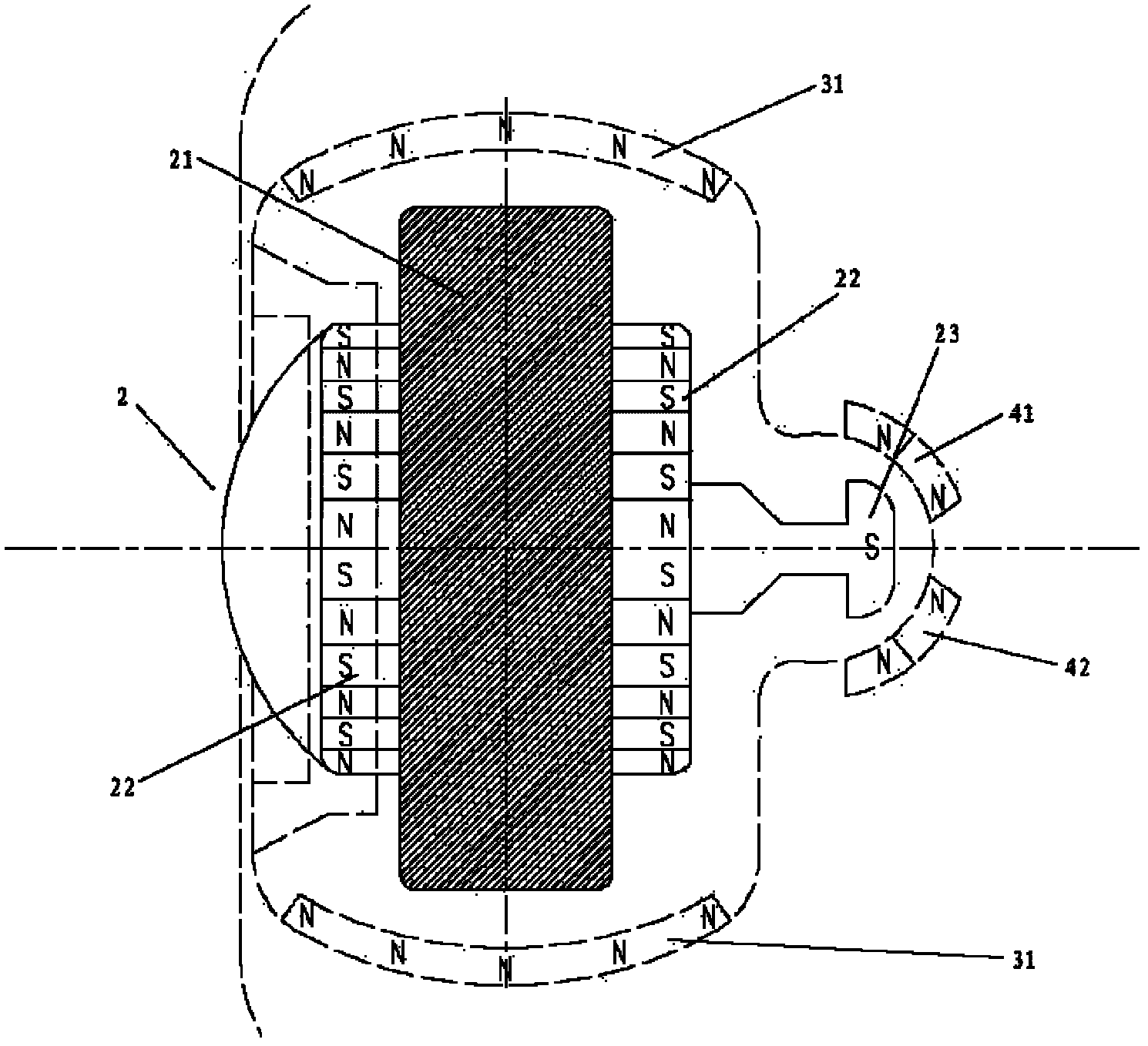

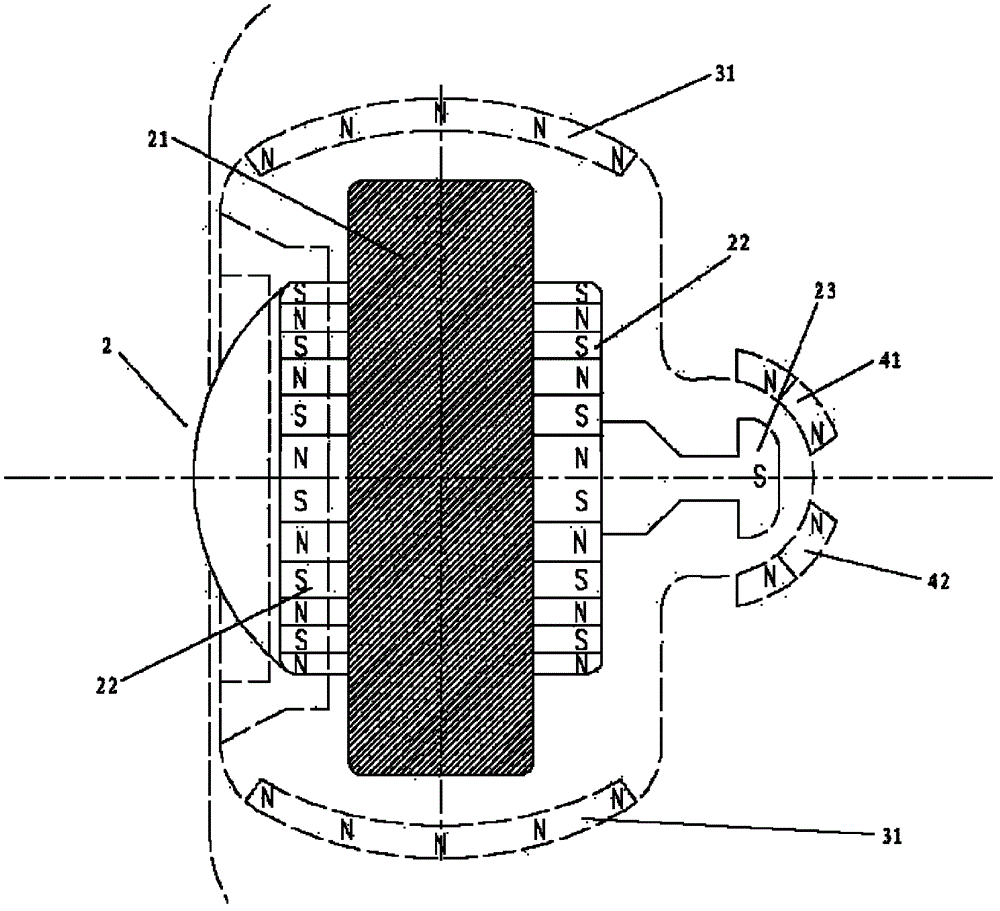

Electric vehicle

ActiveCN103144530ASimple structureEasy to processMotor depositionMagnetic holding devicesEngineeringElectric vehicle

The invention relates to an electric vehicle which comprises a vehicle body, a plurality of magnetic electric wheels, a plurality of third permanent magnet groups, a plurality of control windings and a plurality of second steering windings, wherein the magnetic electric wheels are arranged at the lower part of the vehicle body; each magnetic electric wheel comprises a wheel body, a first permanent magnet arranged at the center of the wheel body, and two second permanent magnets at both ends of the wheel body in the transverse direction; the second permanent magnets towards the inside of he vehicle body are provided with first steering permanent magnets; each third permanent magnet group comprises two third permanent magnets with the same magnetism with the first permanent magnet; the control windings correspond to the magnetic electric wheels; variable currents are conducted inside the control windings to generate alternately changing magnetic fields matched with the second permanent magnets; the second steering windings correspond to the first steering permanent magnets; and variable currents are conducted inside the second steering windings to generate magnetic fields with different intensities and enable the second steering windings to be matched with the first steering permanent magnets. According to the electric vehicle disclosed by the invention, the vehicle body is completely suspended above the magnetic electric wheels, electric energy is converted into the magnetic fields, the power source has no pollution, and the electric vehicle has high utilization rate of energy, a simple structure and high traveling safety.

Owner:BEIQI FOTON MOTOR CO LTD

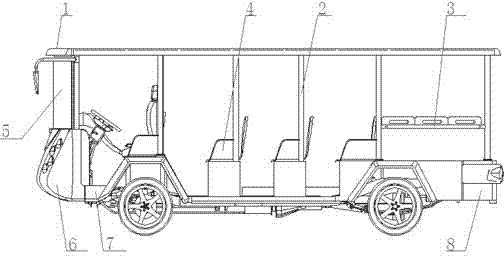

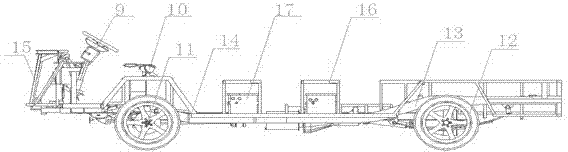

Electric field midibus with novel structure

InactiveCN102358354AInnovative designReasonable ergonomicsVehicle seatsElectric propulsion mountingVehicle frameDrive motor

The invention relates to an electric field midibus with a novel structure. The electric field midibus mainly comprises a novel vehicle body structure, a chassis structure, seat structures and a drive system, wherein the novel vehicle body structure mainly comprises a ceiling, ceiling struts, a tie rod for a rear row of struts, a handrail, a windshield, a front face, a head board and a back board; the chassis structure comprises a boundary-beam type main vehicle frame, an auxiliary vehicle frame, a front steering system, a hand brake system, seat supports, a front suspension, a front wheel system, a rear suspension, a rear wheel system, and a front supporting frame, the auxiliary vehicle frame is welded on the main vehicle frame and is used for supporting a floor, a vehicle body and other components and parts, the front steering system is arranged on the main vehicle frame, the front suspension, the front wheel system, the rear suspension and the rear wheel system are arranged on the main vehicle frame, and the front supporting frame is arranged at a front end of the main vehicle frame; seats comprise a driver seat and a plurality of passenger seats, and the passenger seats comprise a copilot seat at a front row and seats in a middle part and a rear part of midibus; and the drive system mainly comprises a drive motor, a transmission box, a transmission shaft, a rear axle with a main decelerator and a battery pack.

Owner:SUN YAT SEN UNIV +2

Suspension device

InactiveUS8843274B2Reduce vehicle qualityReduce the ratioSpringsVibration dampersElectricityEngineering

A suspension apparatus 1 includes an electric shock absorber 30 having a motor 40 and a ball screw mechanism 35, an electric circuit 101, an inverting amplification circuit 120, and an inertia compensation capacitor Cp. The electric circuit 101 electrically connects the two electricity supply terminals of the motor 40. The inverting amplification circuit 120 is connected to the electric circuit 101. The inertia compensation capacitor Cp is connected to the output terminal O of the inverting amplification circuit 120. As a result of approaching or separating motion between sprung and unsprung members, not only a generated current but also an inertia corresponding current Im which represents an inertial force of a rotation body, such as the ball screw shaft 36 and the rotor of the motor 40, flows through the motor 40 and the electric circuit 101. A current Ip which is antiphase to the inertia corresponding current Im flows through the inertia compensation capacitor Cp. This antiphase current Ip cancels out the inertia corresponding current Im.

Owner:TOYOTA JIDOSHA KK

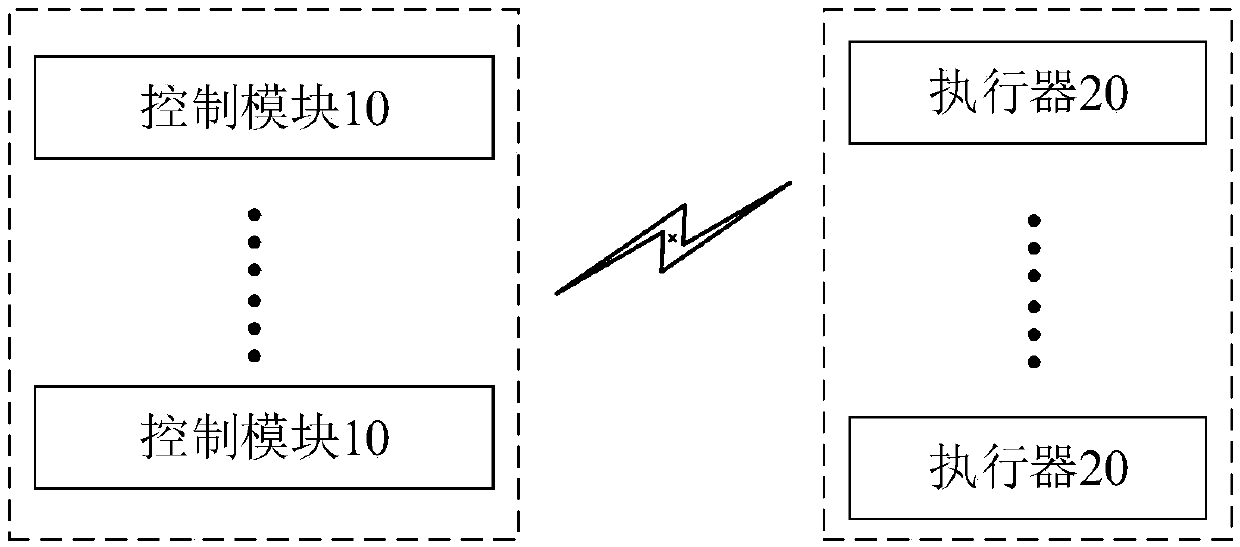

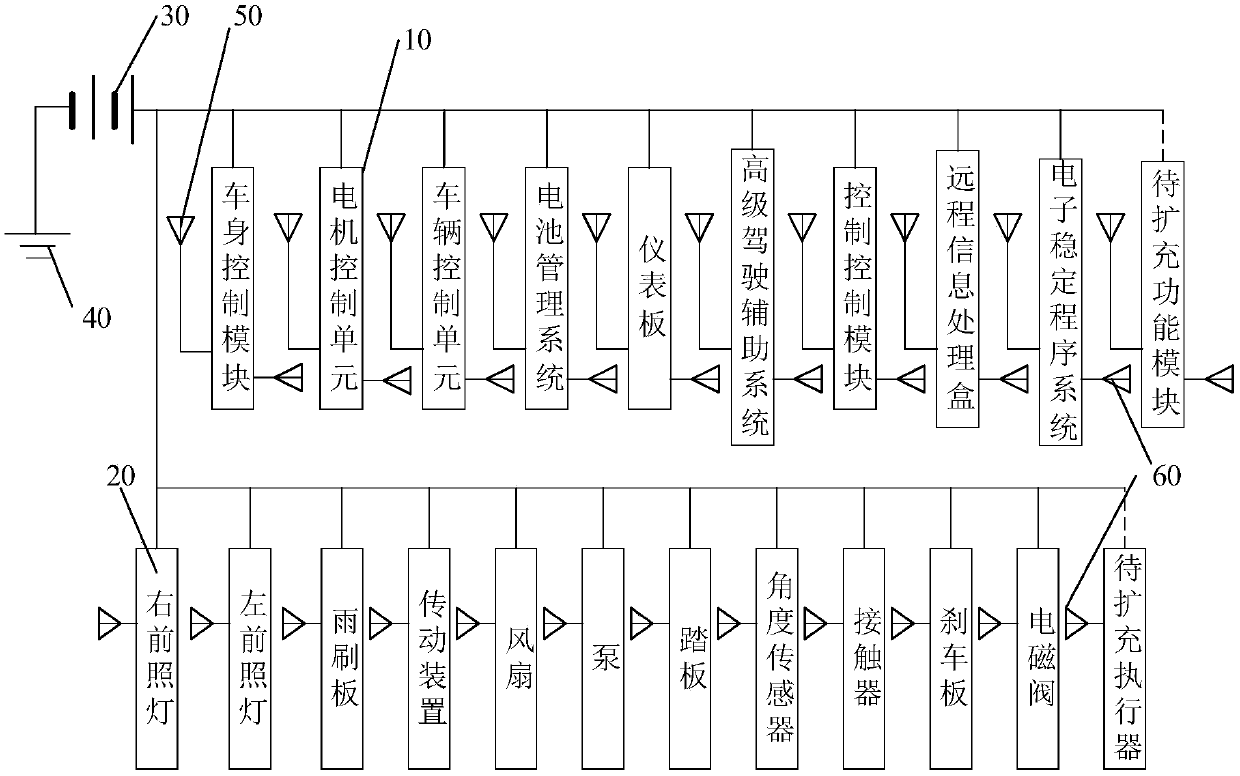

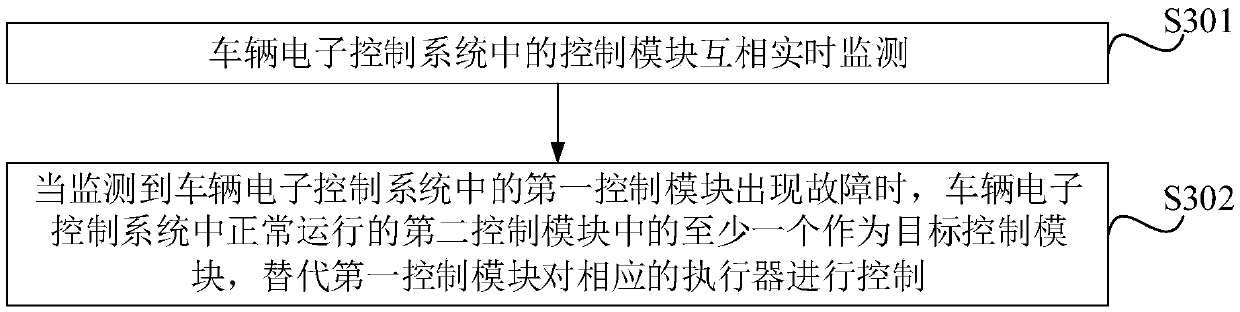

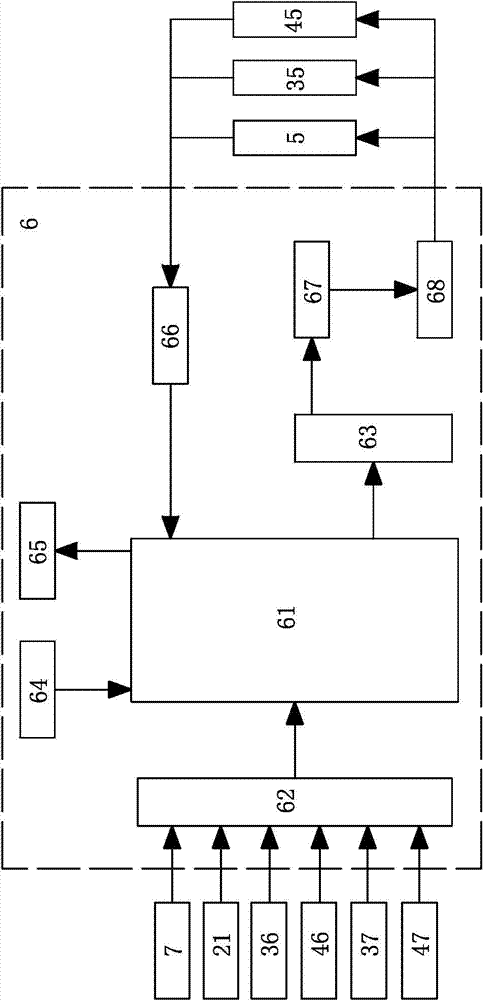

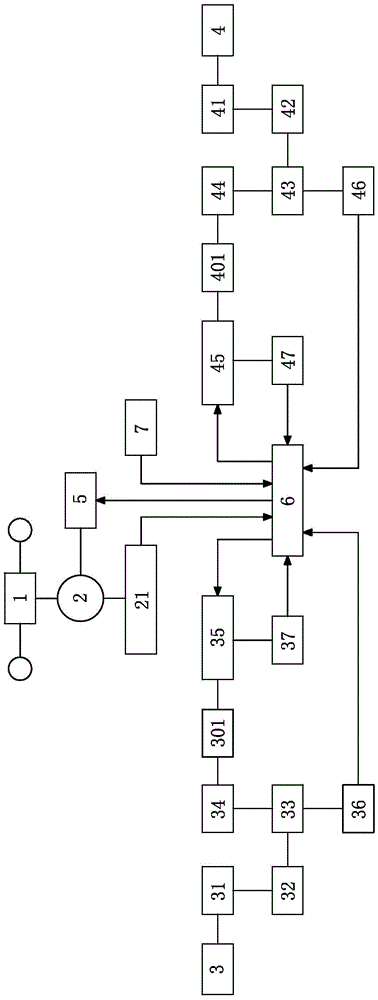

Vehicle electronic control system and control method thereof

InactiveCN109552217AReduce in quantityLow costElectric/fluid circuitControl systemElectronic control system

The invention provides a vehicle electronic control system and a control method thereof and relates to the technical field of vehicle control. The vehicle electronic control system comprises at leastone control module and at least one executor; and each control module is in wireless communication connection with the corresponding executor and used for wirelessly controlling the corresponding executor. Compared with the prior art, due to the adoption of the wireless communication mode between each control module and the corresponding executor, the number of control lines and the number of hardware interfaces are reduced, so that the cost and the mass of a whole vehicle are reduced, meanwhile, the matching complexity of the hardware interfaces is reduced to a great degree, and a control framework is greatly simplified.

Owner:HUMAN HORIZONS (JIANGSU) TECH CO LTD

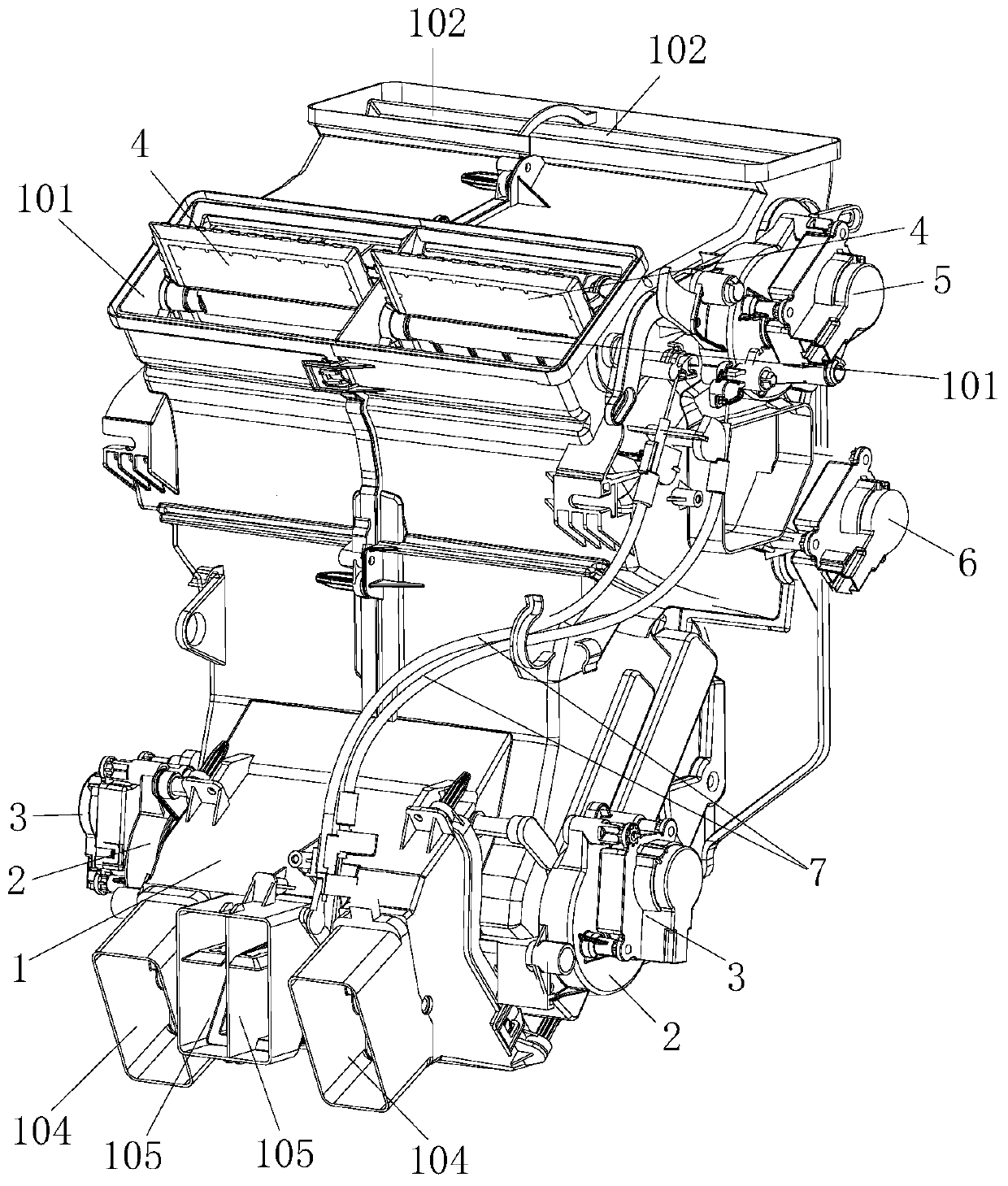

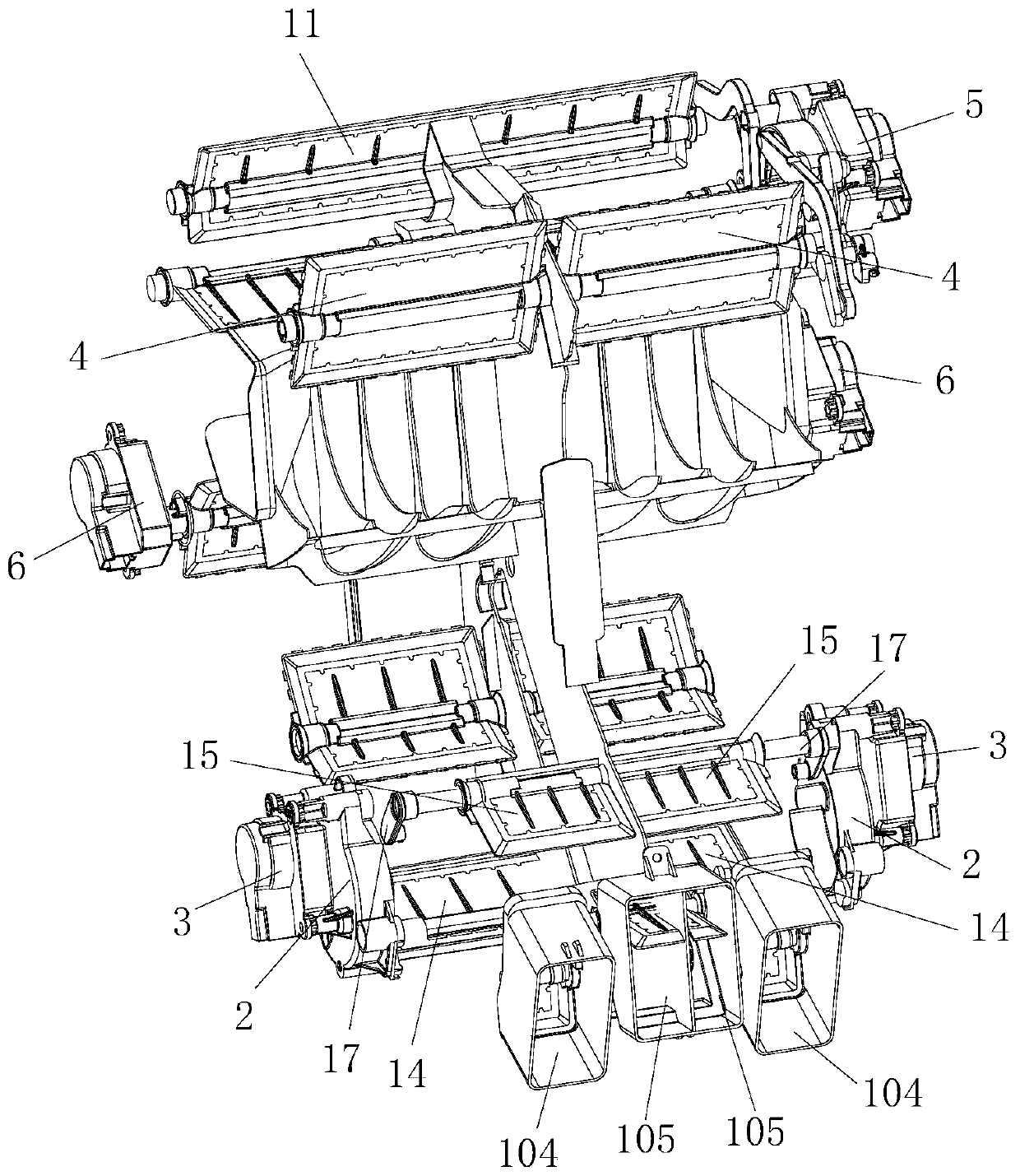

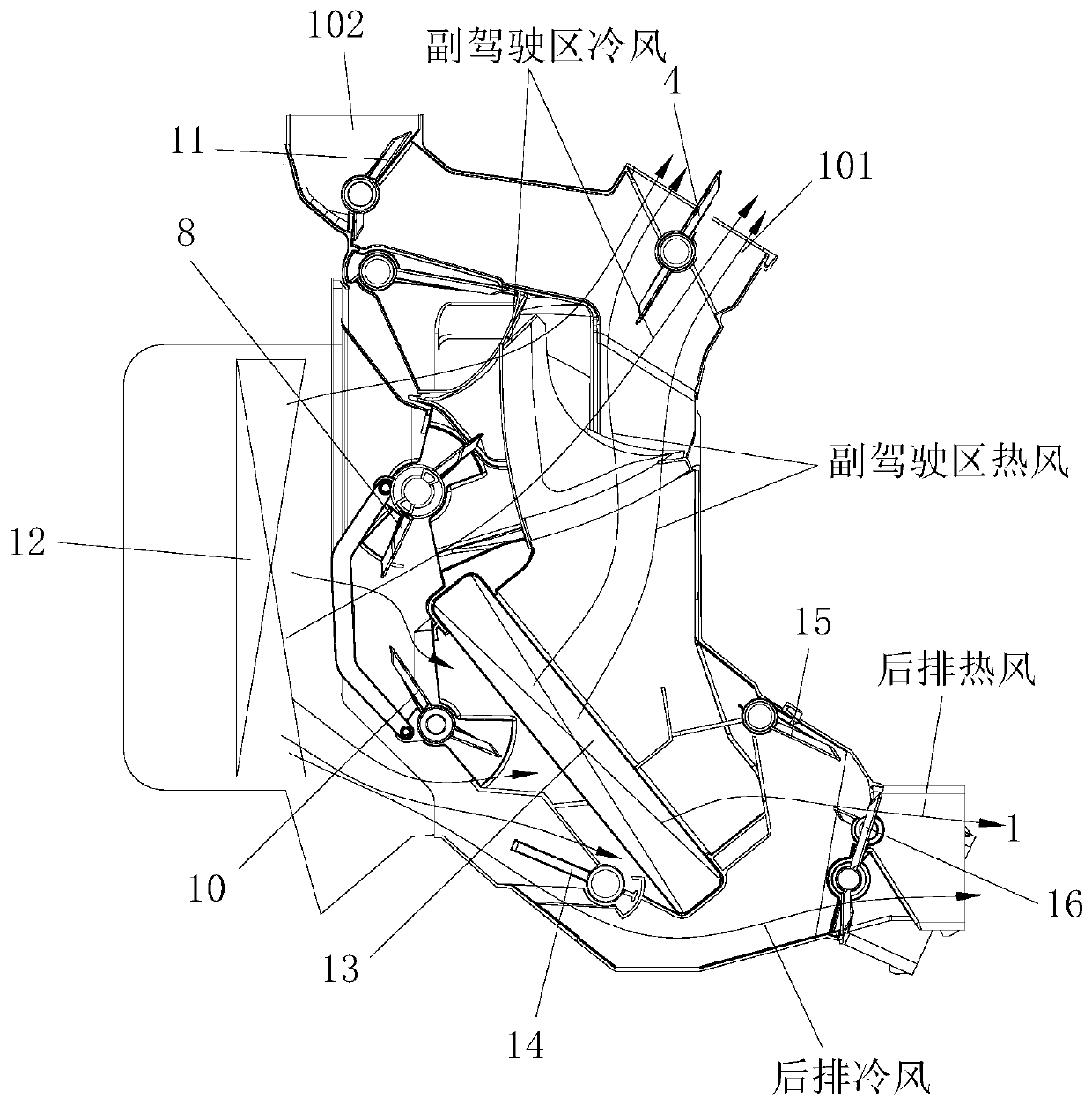

Automobile four temperature zone air conditioner control device and automobile four temperature zone air conditioner control system

InactiveCN109774414AFew partsAchieve independent controlAir-treating devicesVehicle heating/cooling devicesCold airTemperature control

The invention relates to an automobile four temperature zone air conditioner control device and an automobile four temperature zone air conditioner control system. The automobile four temperature zoneair conditioner control device mainly comprises a shell, temperature control parts and an air supply control part; a main driving area air duct, an auxiliary driving area air duct, a main driving side rear air exhaust duct and an auxiliary driving side rear air exhaust duct, which are all provided with a cold air duct and a hot air duct, are separated in the shell, an air mixing area below the cold air ducts and the hot air ducts and an air outlet communicated with the air mixing area are also separated in the shell, four temperature control parts are respectively provided arranged corresponding to the main driving zone air duct, the auxiliary driving zone air duct, the main driving side rear air exhaust duct and the auxiliary driving side rear air exhaust duct. The air supply control part comprises air supply doors and air supply control mechanisms, wherein the air supply doors are rotatably arranged in the air ducts, and the air supply control mechanisms are used for controlling theopening and closing of the air supply doors. The device can achieve the independent control of the temperatures in the air ducts of the four zones, thereby improving the comfort of the main driver, the auxiliary driver and the rear passengers.

Owner:MIND ELECTRONICS APPLIANCE CO LTD

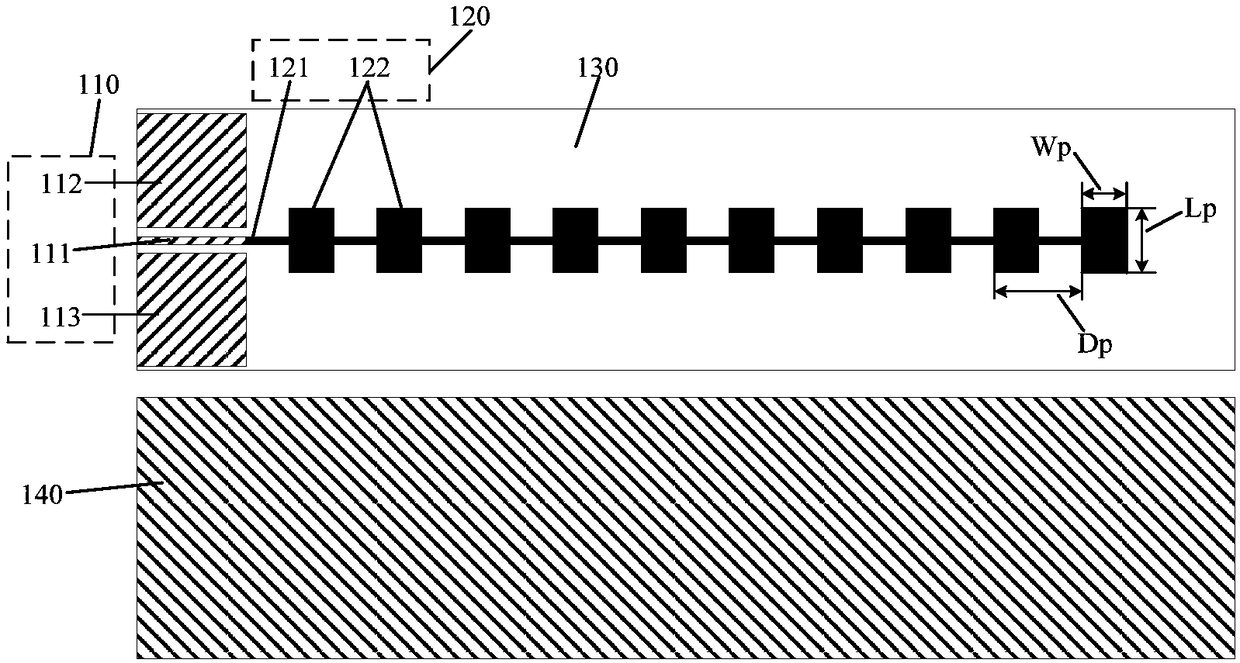

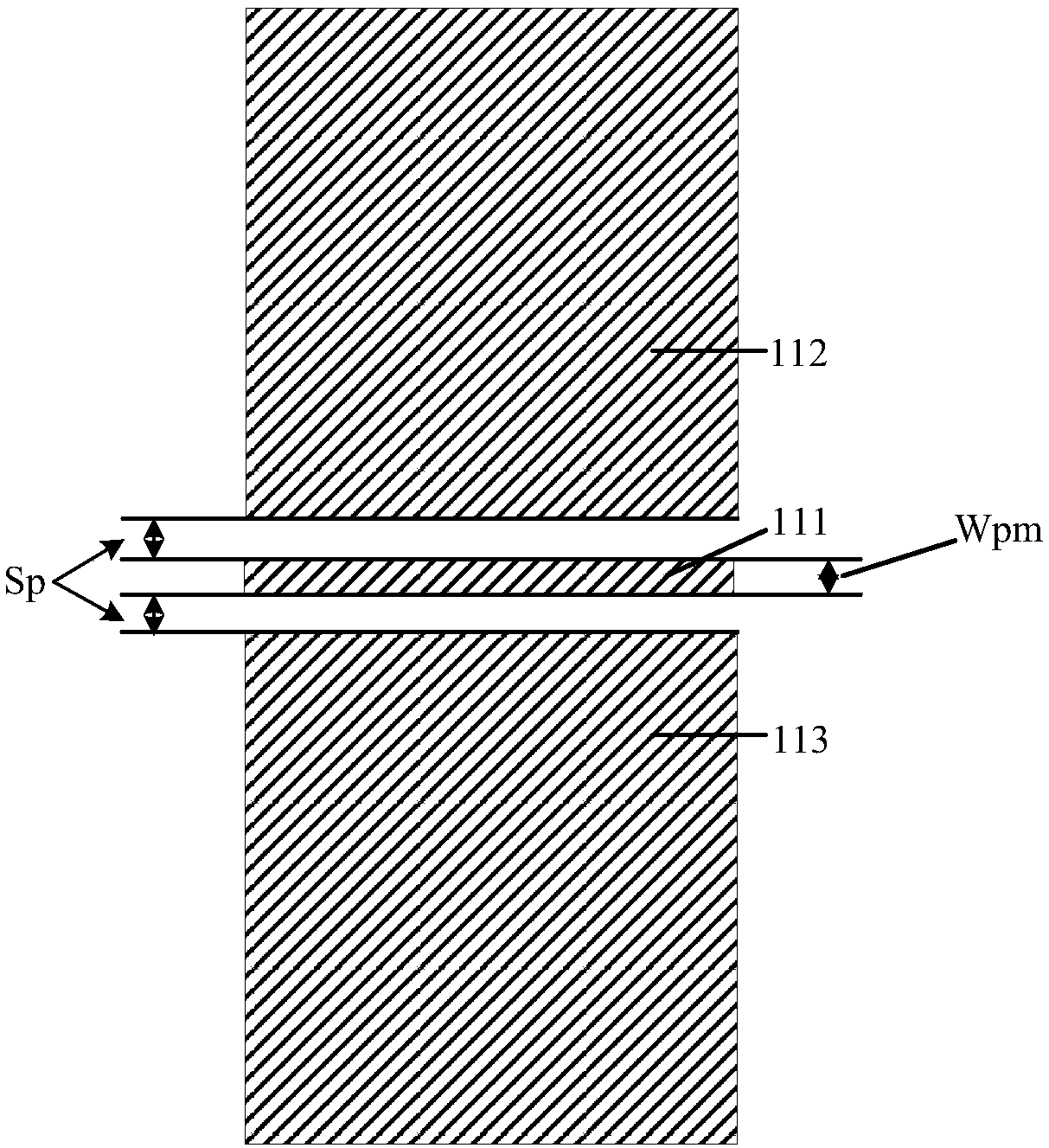

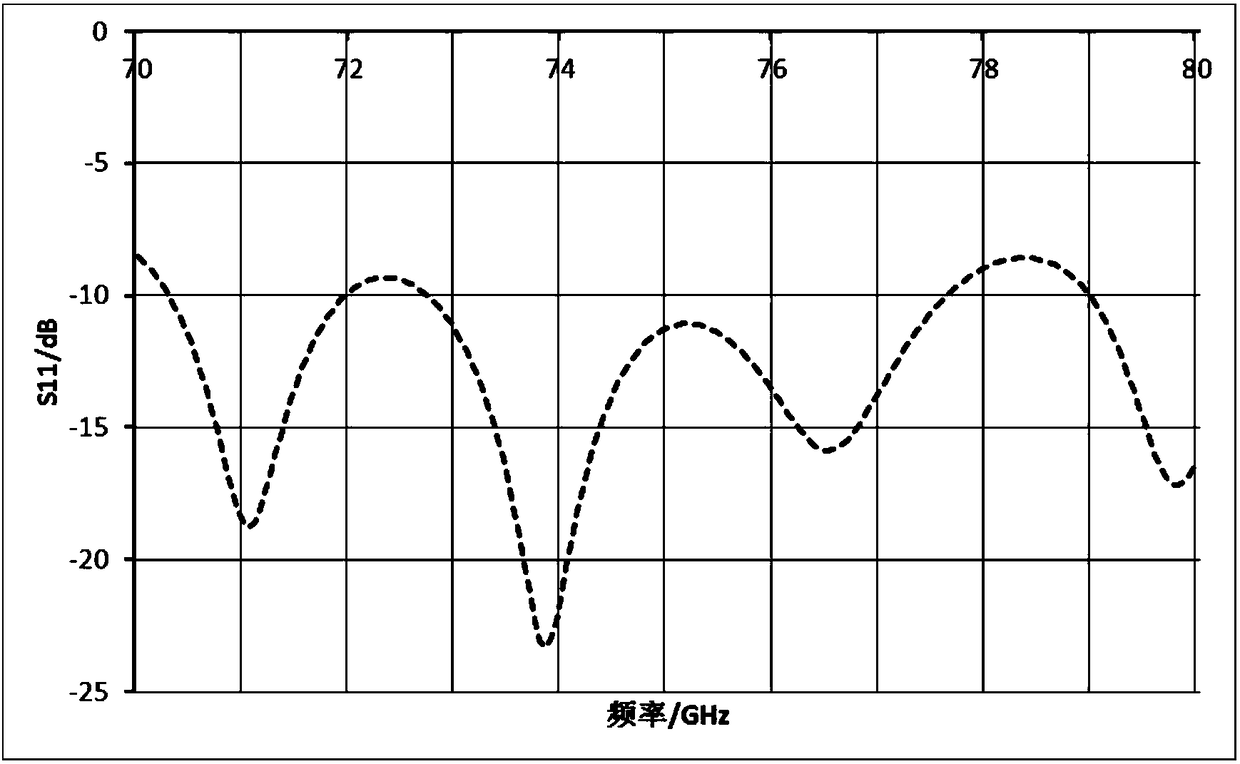

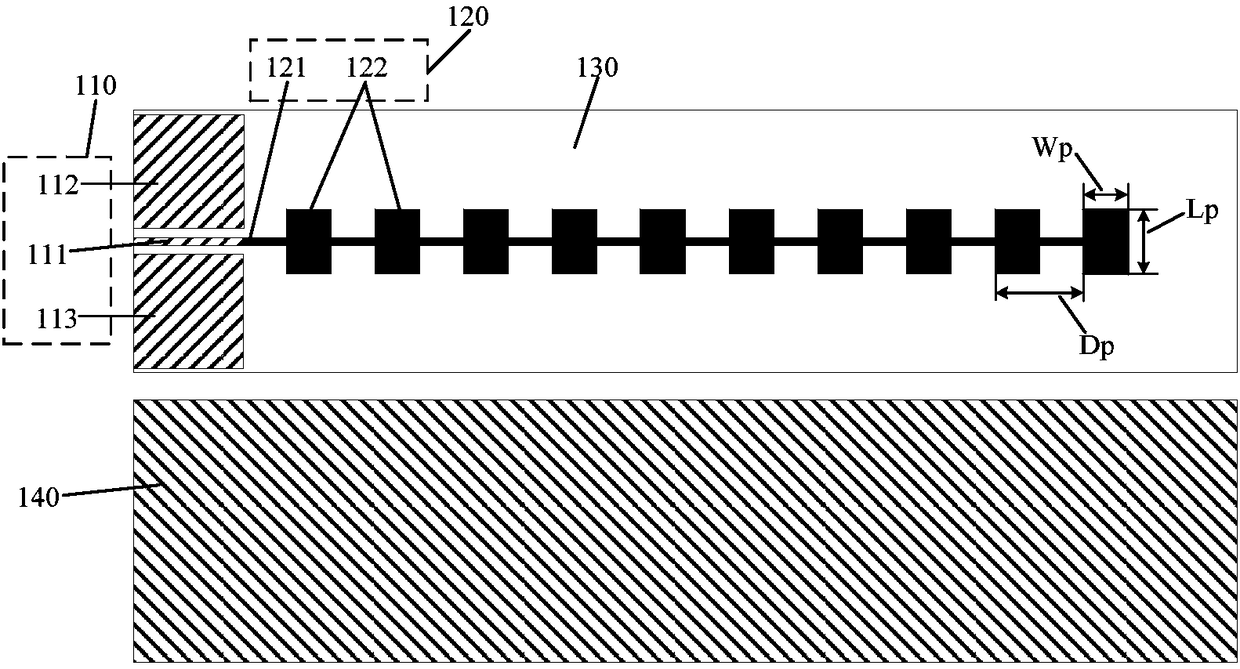

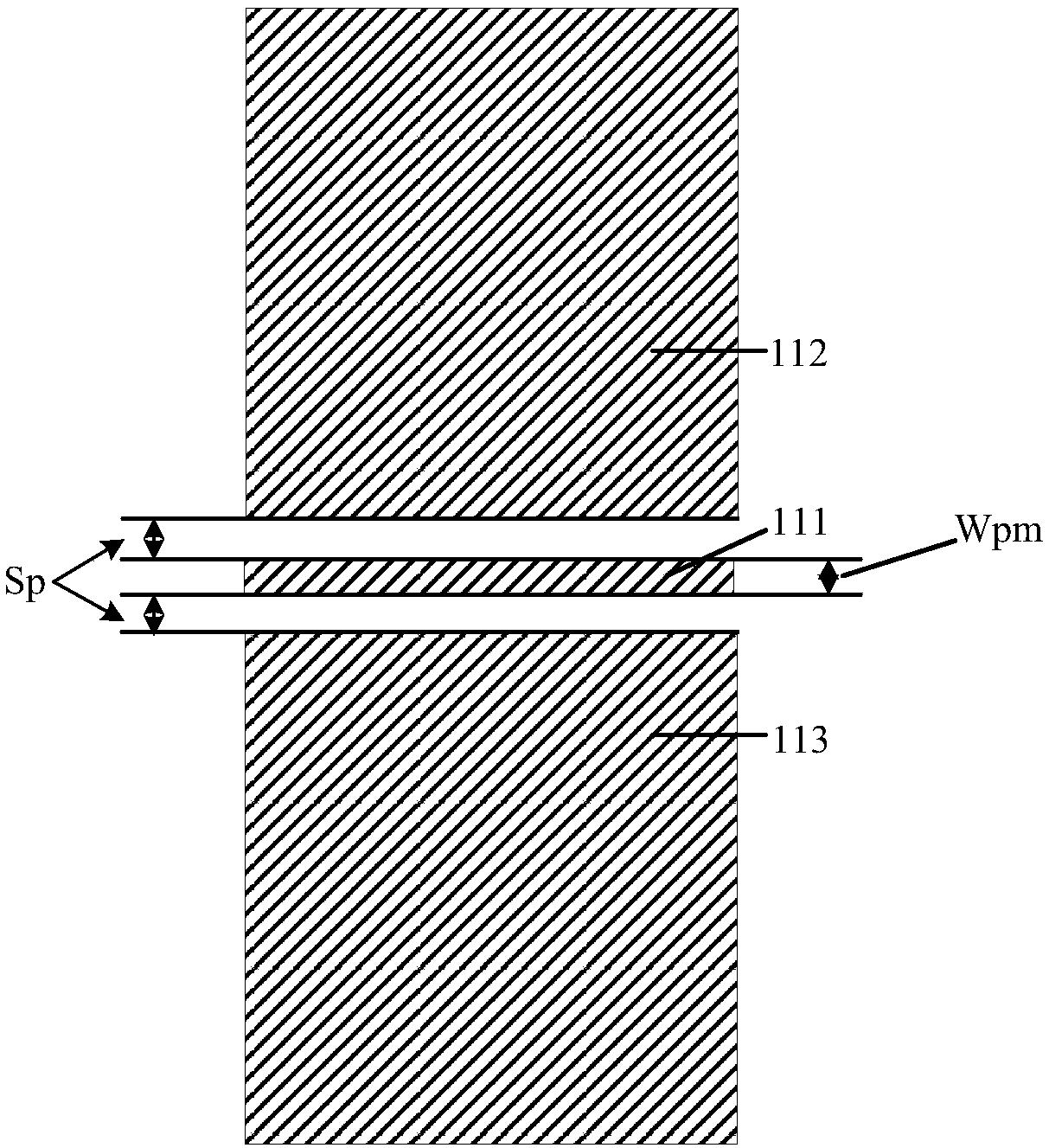

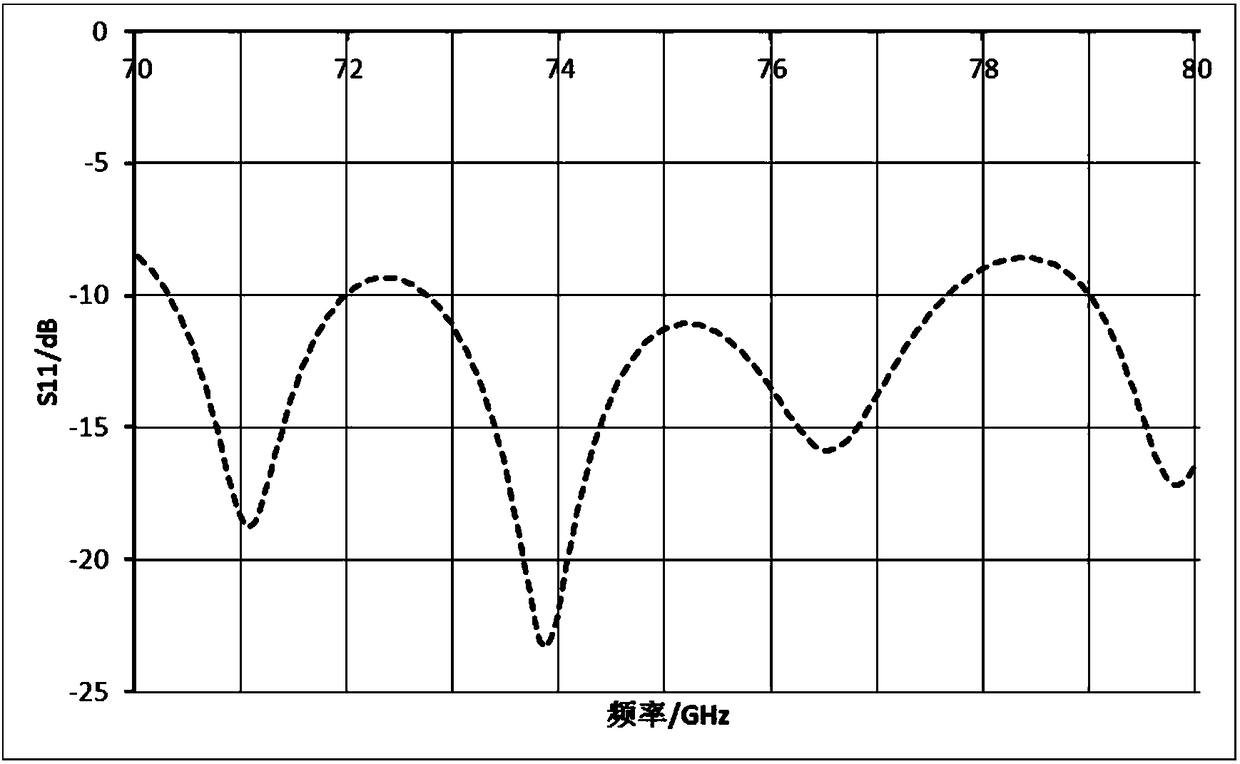

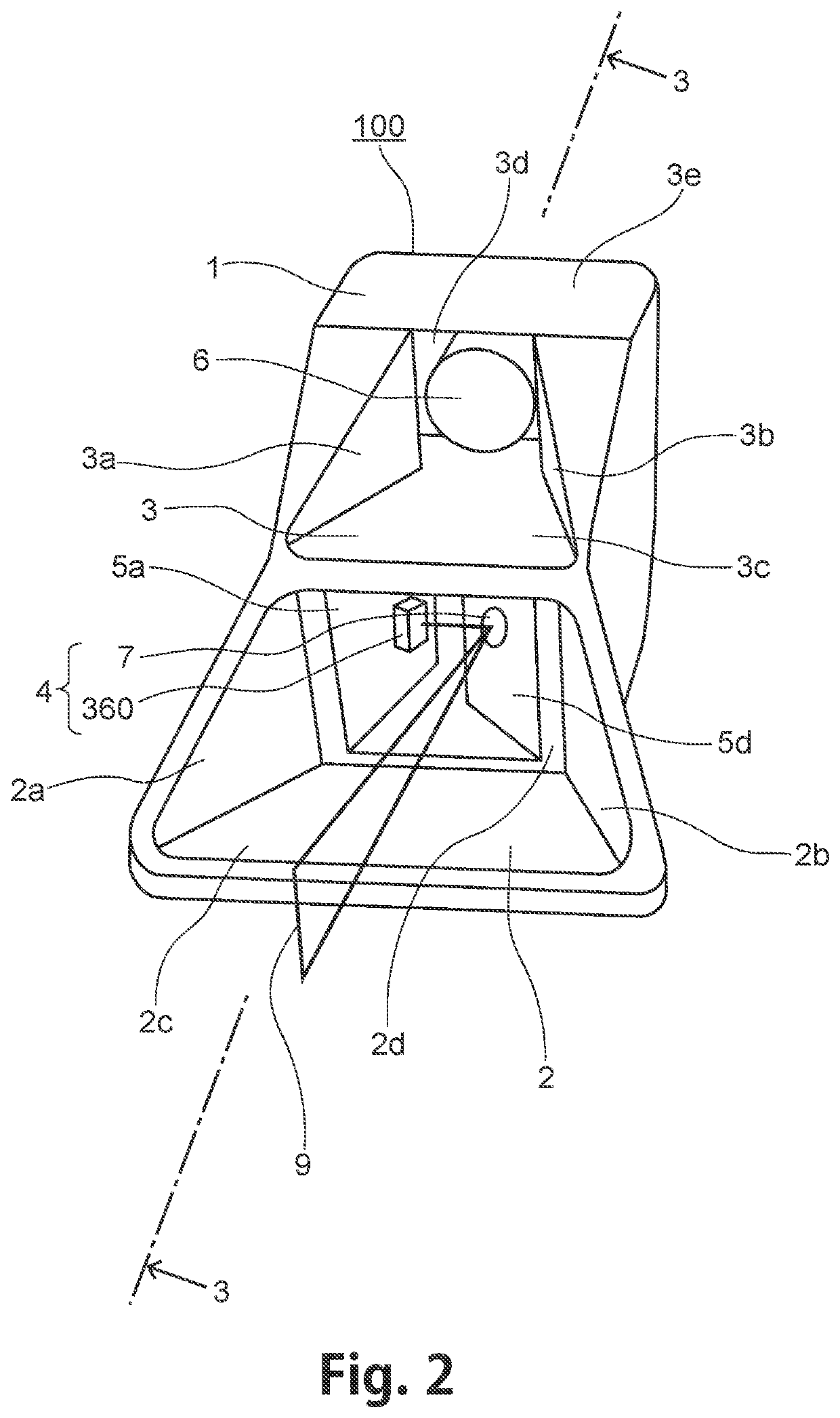

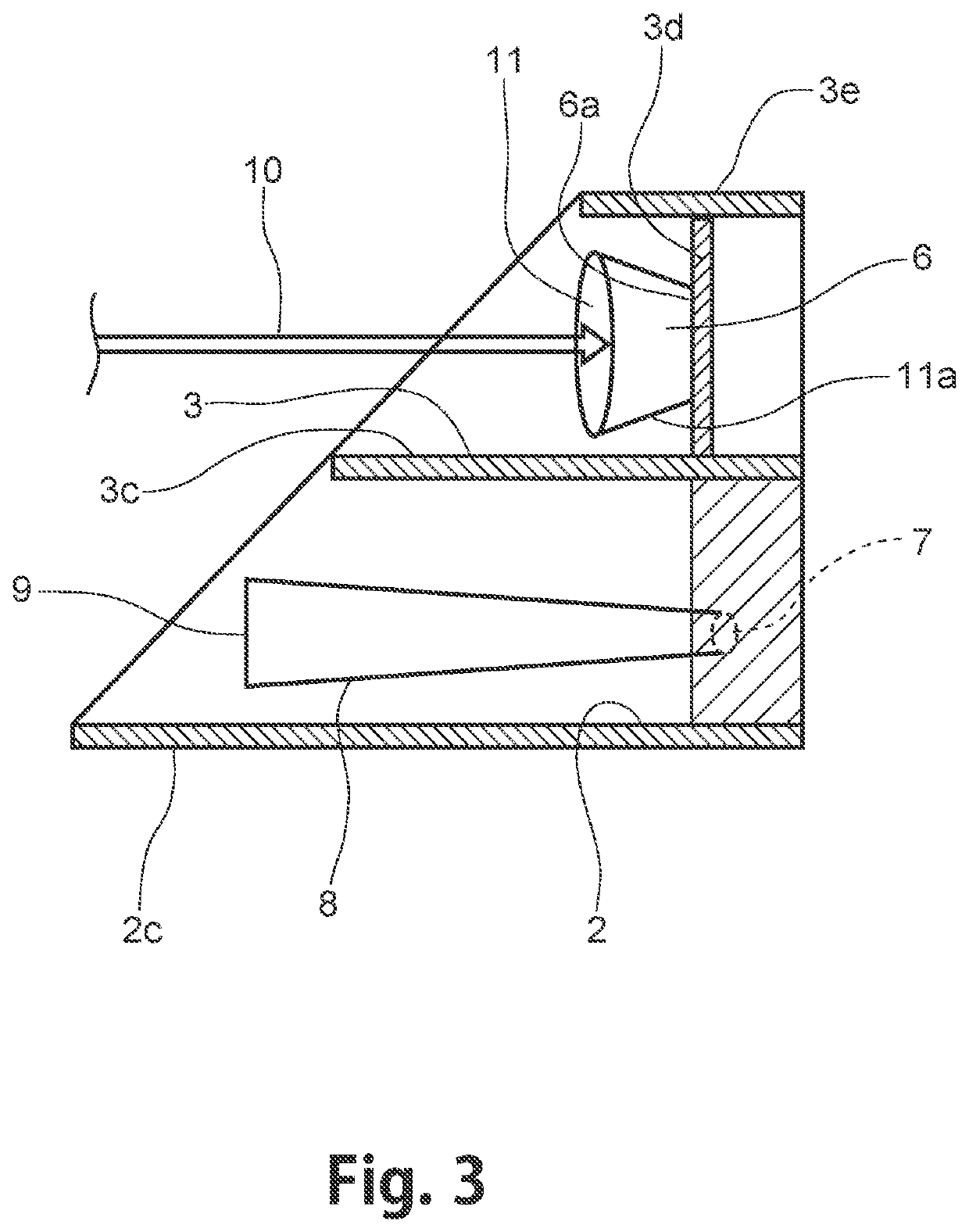

Antenna part, vehicle-mounted radar and automobile

ActiveCN109428175ALow priceLight in massParticular array feeding systemsAntenna adaptation in movable bodiesRadarDielectric substrate

The invention discloses an antenna part, a vehicle-mounted radar and an automobile. The antenna part comprises a dielectric substrate, a coplanar waveguide assembly, an array antenna, a wave beam width adjustment assembly and a back grounding plate, wherein the coplanar waveguide assembly is formed at one side of the dielectric substrate, the array antenna is connected with the coplanar waveguideassembly, the array antenna comprises at least one microstrip feeding line and a plurality of array patches, the plurality of array patches are arranged on the microstrip feeding line and are dividedto two groups, the widths of the two groups of array patches are different, the wave beam width adjustment assembly is arranged in a circling the array antenna, and the back grounding plate is formedat the other side of the dielectric substrate and covers a part right below the coplanar waveguide assembly, the array antenna and the wave beam width adjustment assembly. The antenna part and an MMICare easily arranged on the same surface of the dielectric substrate, the application area of the dielectric substrate is favorably reduced, the integral cost of the vehicle-mounted radar is reduced,moreover, a metal structure member containing a waveguide cavity is not needed to be used, and the integral quality of the radar can be reduced.

Owner:BYD CO LTD

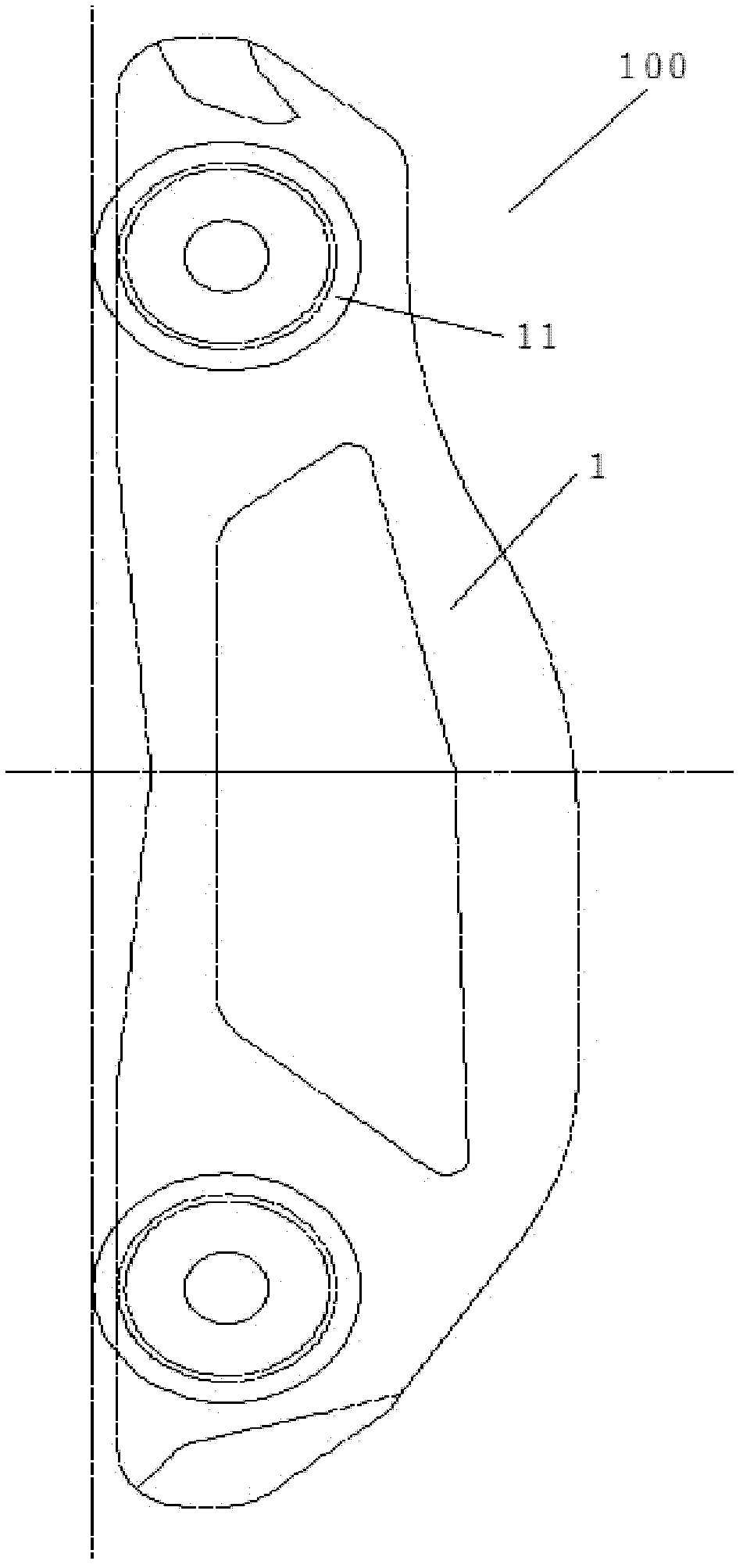

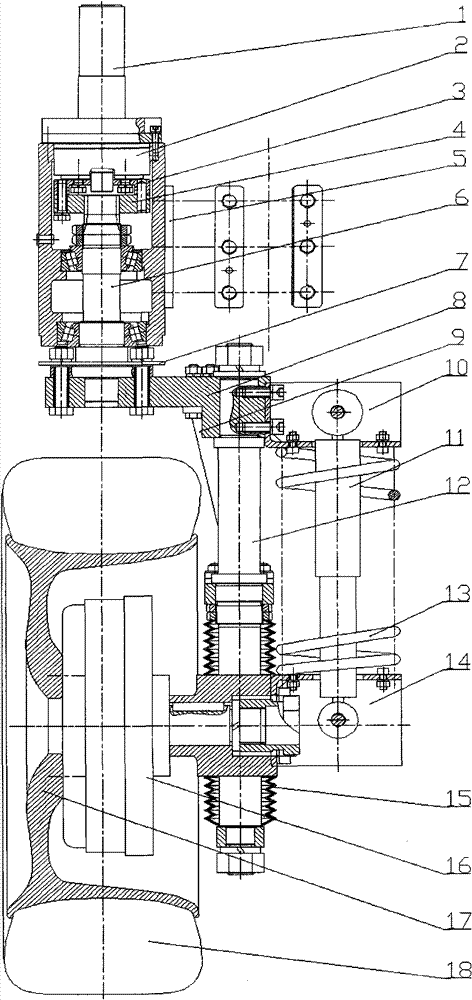

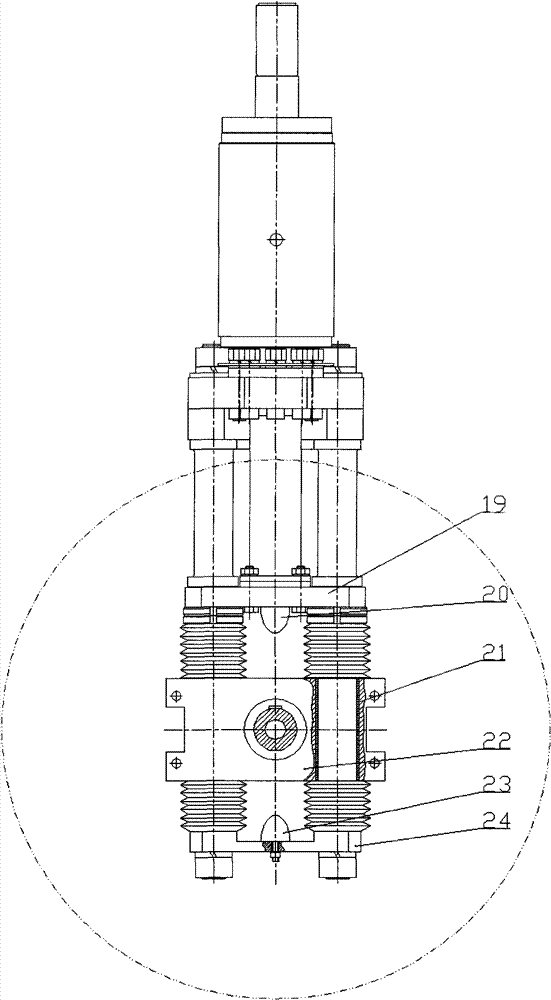

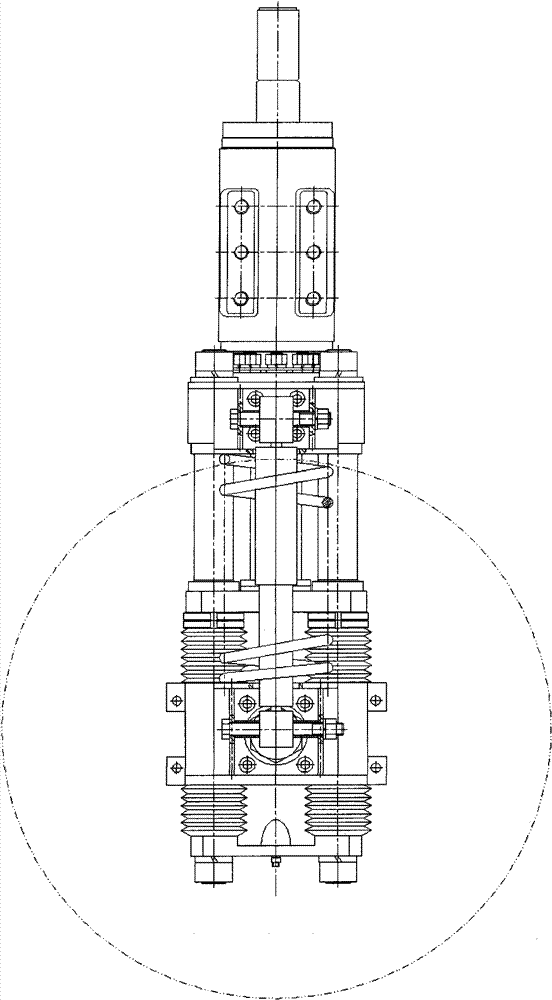

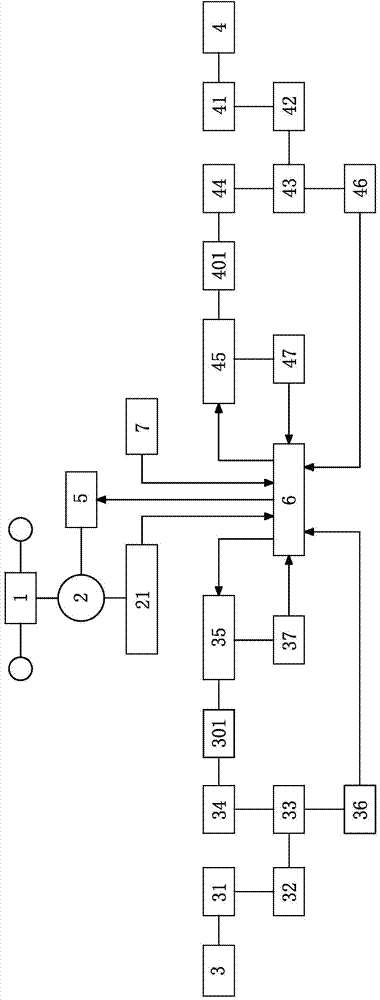

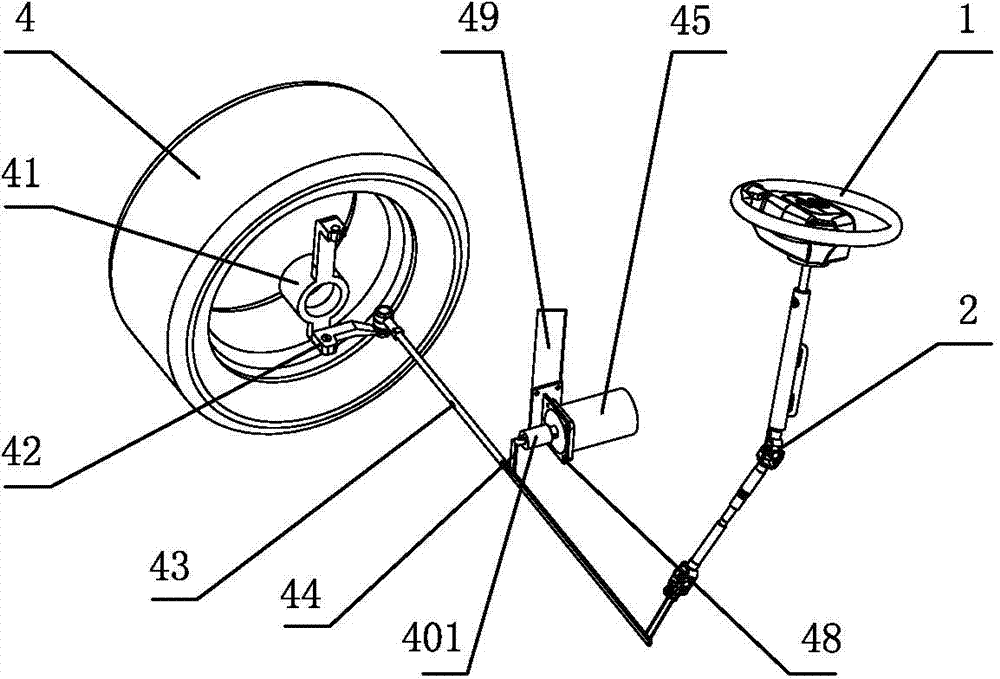

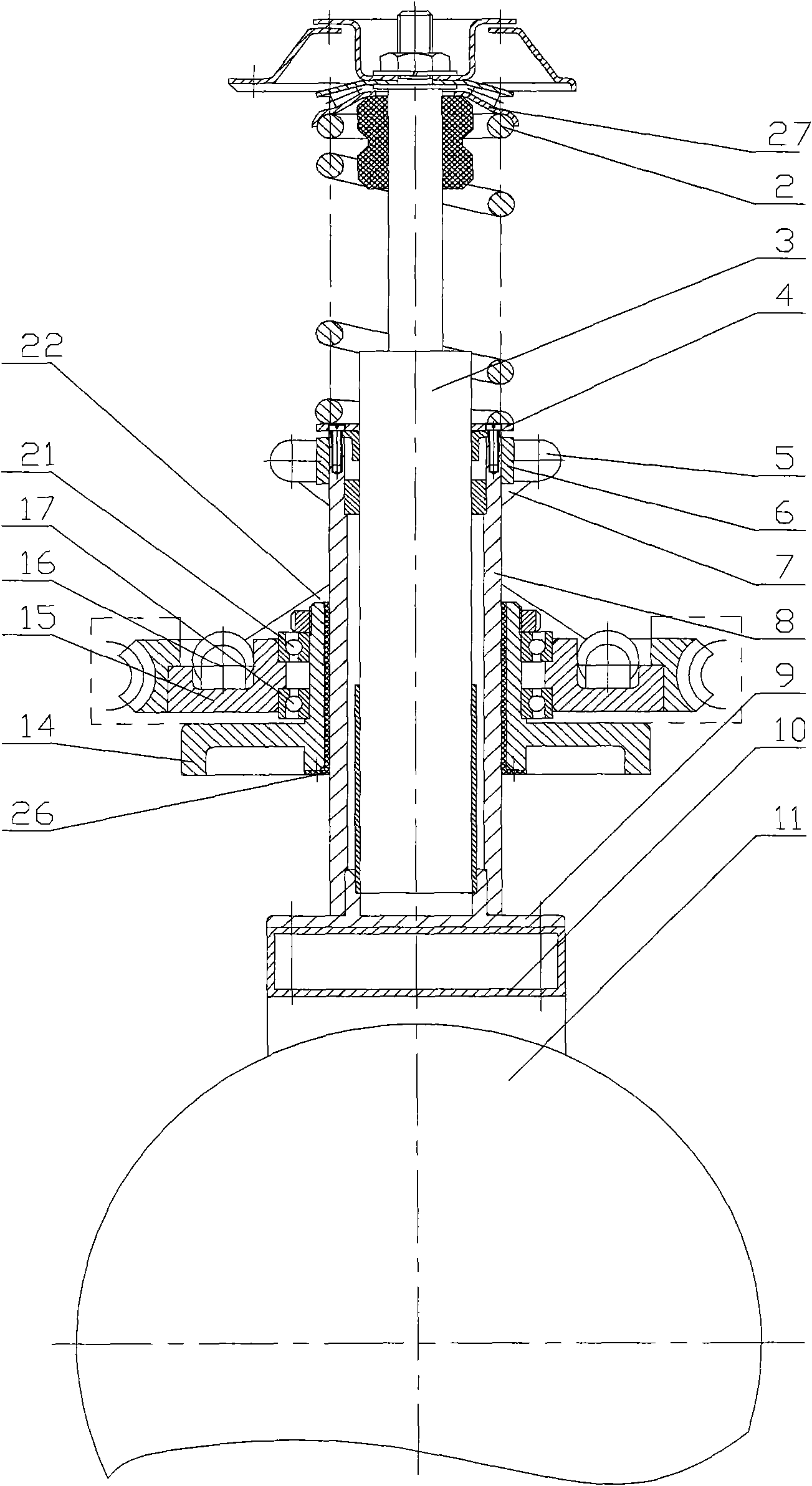

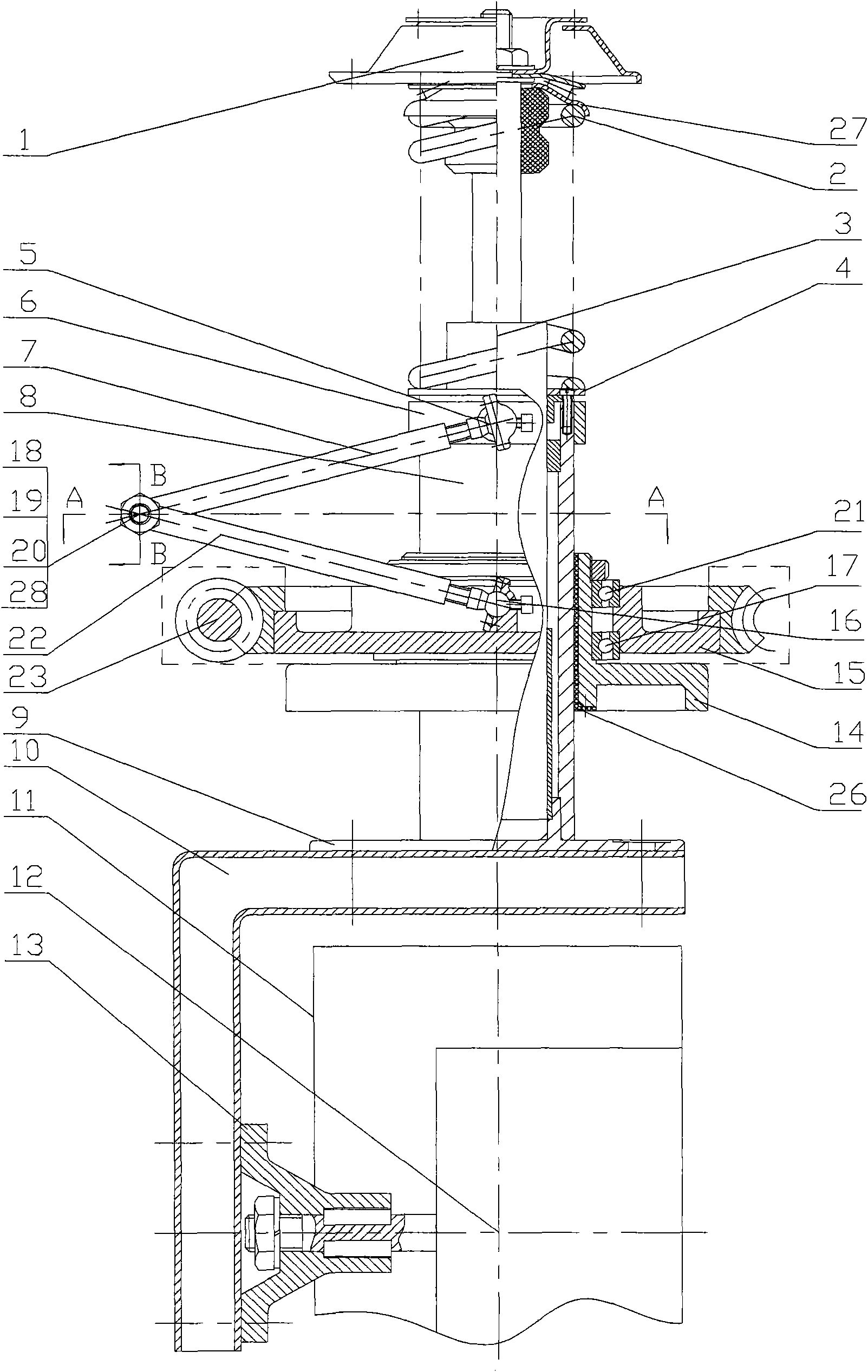

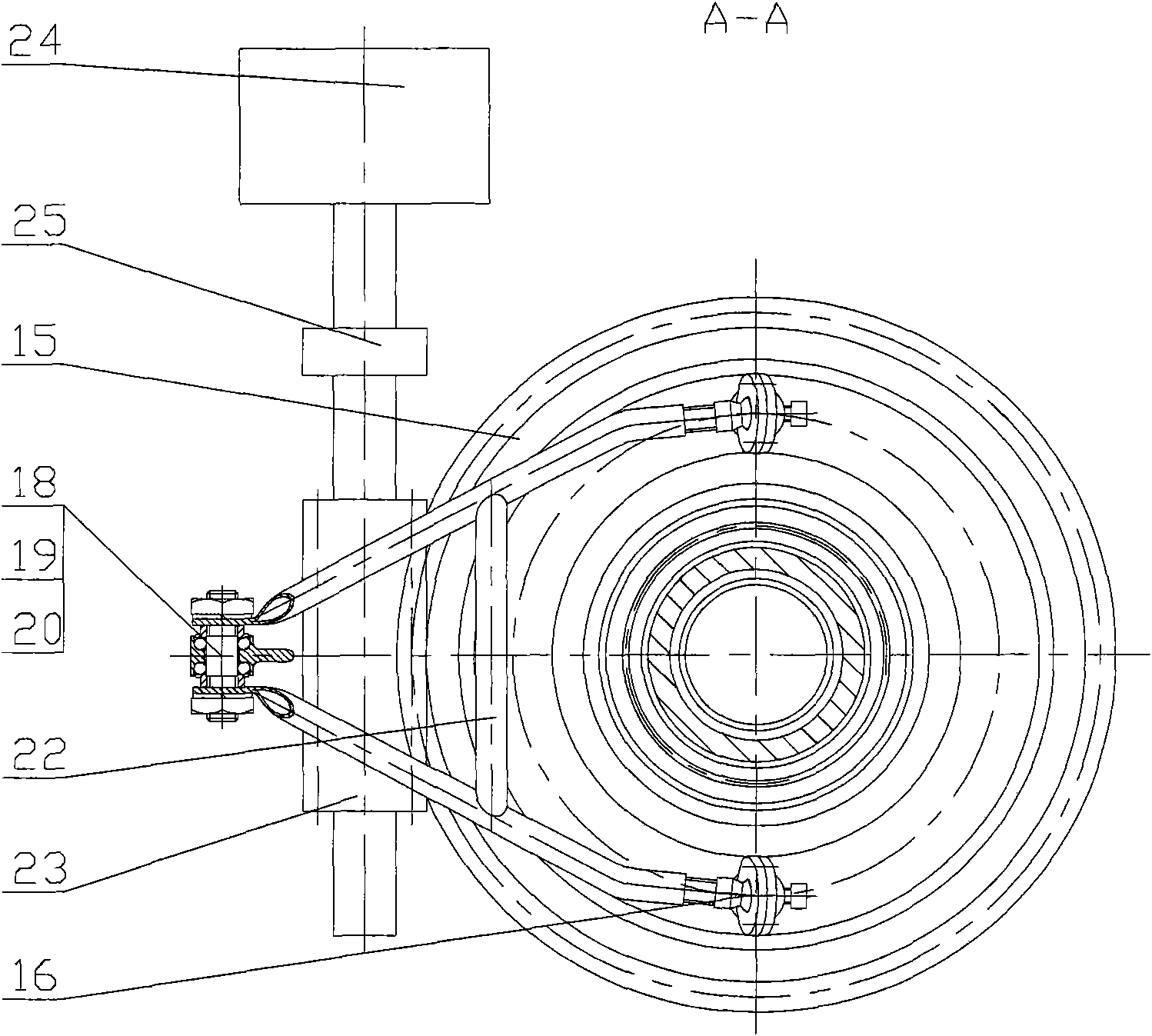

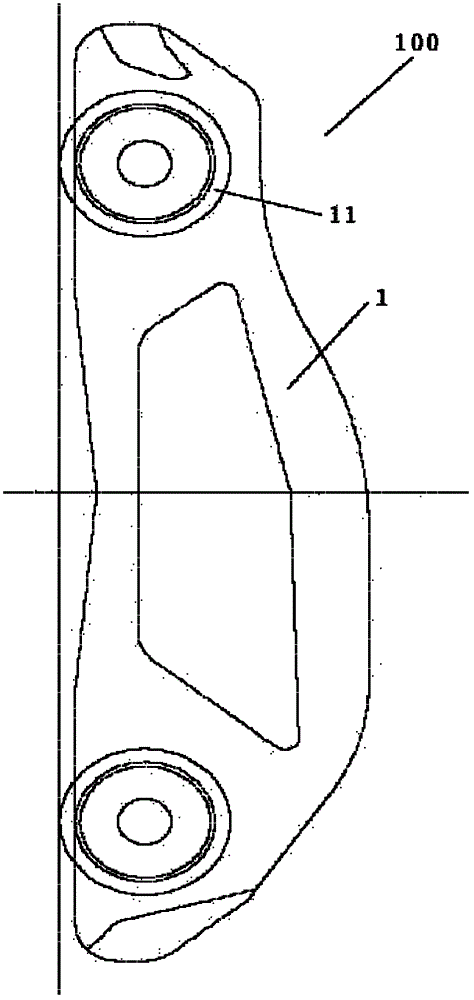

Main pin zero bias wire-controlled independent driven and steering automobile running mechanism and electric vehicle

InactiveCN101973307BAvoid interferenceSimple structureSteering linkagesElectrical steeringVehicle frameReduction drive

The invention discloses a main pin zero bias wire-controlled independent driven and steering automobile running mechanism and an electric vehicle for solving the problems of complex mechanism and low vehicle stability. The mechanism consists of a steering component, a suspension component and a wheel component. The steering component consists of a main pin assembly and a steering vertical shaft assembly. The main pin assembly comprises a steering motor (1), a speed reducer (2), a speed reducer output flange (3), a main pin sleeve (5), a main pin (6) and a coding disc (7); and the steering vertical shaft assembly comprises a main steering arm (8), a steering vertical shaft (12), an upper distance plate (19) and a lower distance plate (24). The suspension component comprises an upper springseat (10), a shock absorber (11), a spring (13) and a lower spring seat (14). The wheel component comprises a hub motor (16), a wheel (18) and a wheel bracket (22). The electric vehicle consists of aframe (28), the main pin zero bias wire-controlled independent driven and steering automobile running mechanism (27) and an electric control system.

Owner:JILIN UNIV

Antenna component, vehicle-borne radar and automobile

InactiveCN109428165AReduce the use of areaLow priceAntenna adaptation in movable bodiesRadiating elements structural formsRadarCoplanar waveguide

The invention discloses an antenna component, a vehicle-borne radar and an automobile. The antenna component comprises a medium substrate, a coplanar waveguide component, an array antenna and a back ground connection plate formed on the other side of the medium substrate, wherein the coplanar waveguide component is formed on one side of the medium substrate; the array antenna is formed on one sideof the medium substrate, is connected with the coplanar waveguide component and comprises at least one micro-strip feeder line and a plurality of array patches arranged on the top of the micro-stripfeeder line, wherein the plurality of array patches are divided into two groups, and the two groups of array patches have different widths; and the back ground connection plate is formed on the otherside of the medium substrate and is covered just below the coplanar waveguide component and the array antenna. The coplanar waveguide component and the array antenna of the antenna component are arranged on the same side of the medium substrate so as to be easy in connecting with the tiny pins of an MMIC (Monolithic Microwave Integrated Circuit) and to be easy in being arranged on the same side ofthe medium substrate with the MMIC, so that the antenna component is favorable for reducing the use area of the medium substrate and lowering the integral price of the vehicle-borne radar, in addition, a metal structural member which contains a waveguide cavity does not need to be used, and the integral quality of the radar can be lowered.

Owner:BYD CO LTD

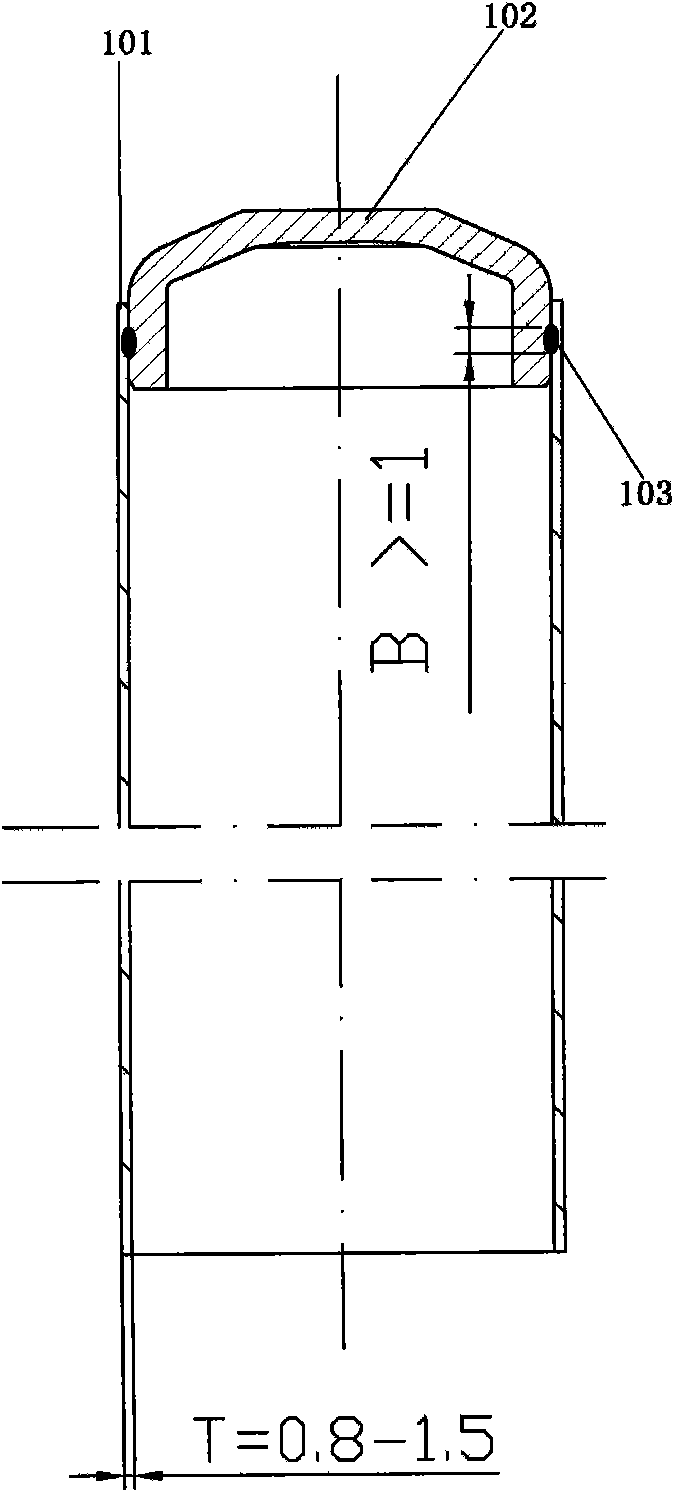

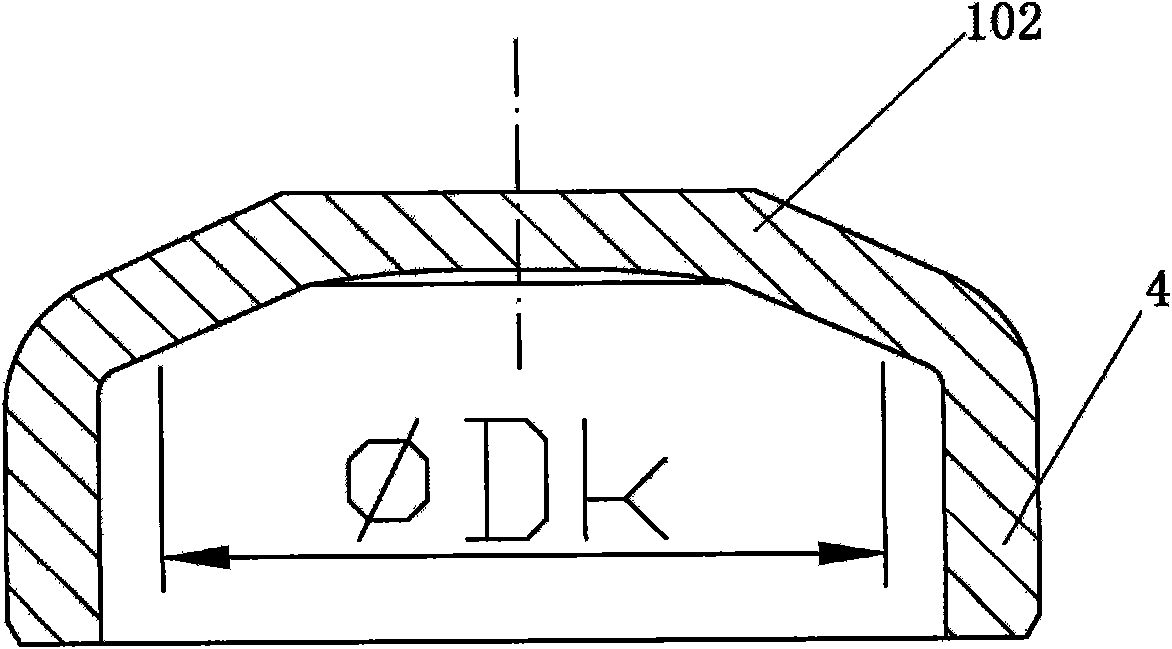

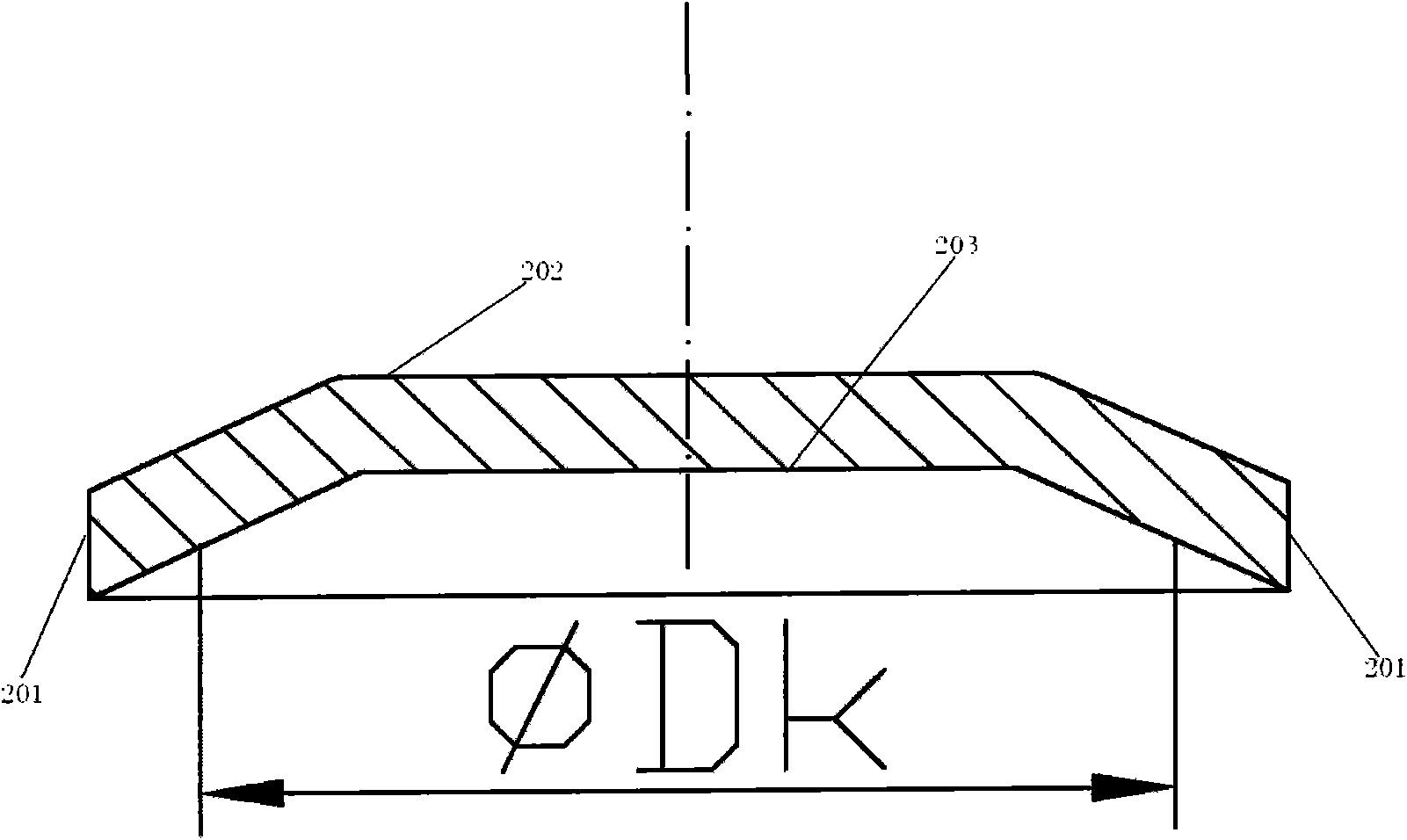

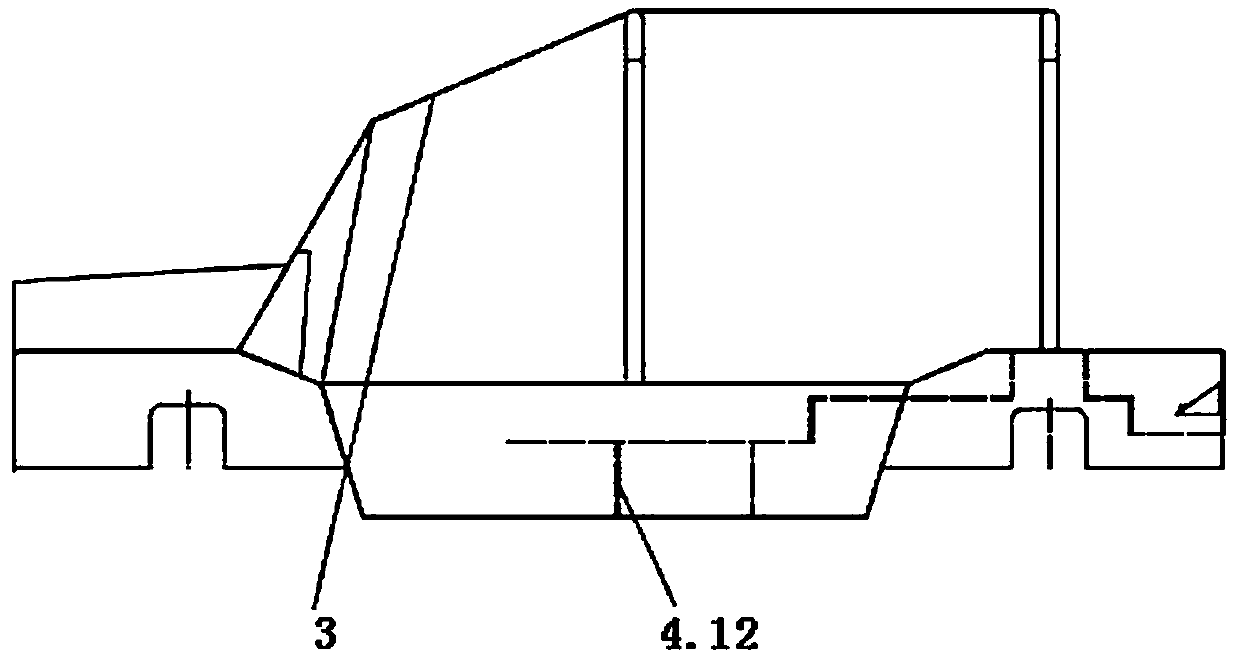

Outer cylinder assembly structure and welding joint for dual-cylinder shock absorber

InactiveCN101769356AImprove security levelAvoids the problem of easy formation of uneven wrinkles on the end sectionSpringsShrinkage connectionsSeam weldingTungsten

The invention discloses an outer cylinder assembly structure and welding joint for a dual-cylinder shock absorber; the outer cylinder assembly structure is composed of an outer cylinder part and a bottom cover part welded together, the wall thickness of the outer cylinder part is no more than 1.5 mm, the bottom cover part is provided with an outer cylindrical surface matched with the outer cylinder part, and the length of the outer cylindrical surface is no more than 5 mm. a welding joint employing melting and no pressure-welding is adopted between the bottom cover part and the outer cylinder part, the melting adopts the currently-newest low-cost and efficient welding technique, namely the pulse electric arc welding with speed of 1m / min, dual argon tungsten-arc welding or dual-wire welding; compared with the traditional welding joint which adopts resistance seam welding and is between the bottom cover and outer cylinder parts of the dual-cylinder shock absorber, the shock absorber can reduce the material quantity and the dead weight, and accordingly facilitates reducing the product cost and realizing better finished vehicle performance.

Owner:刘学忠

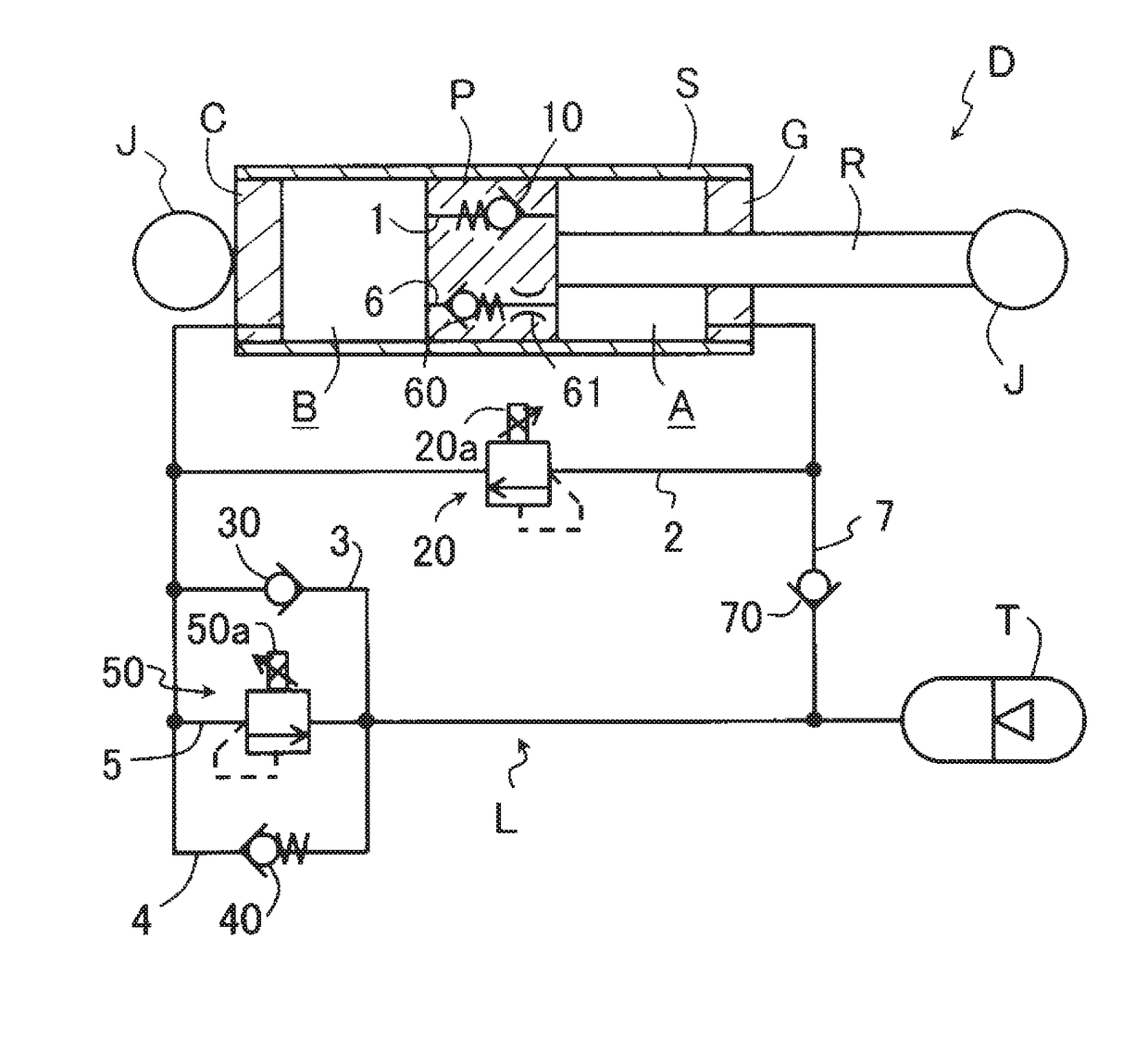

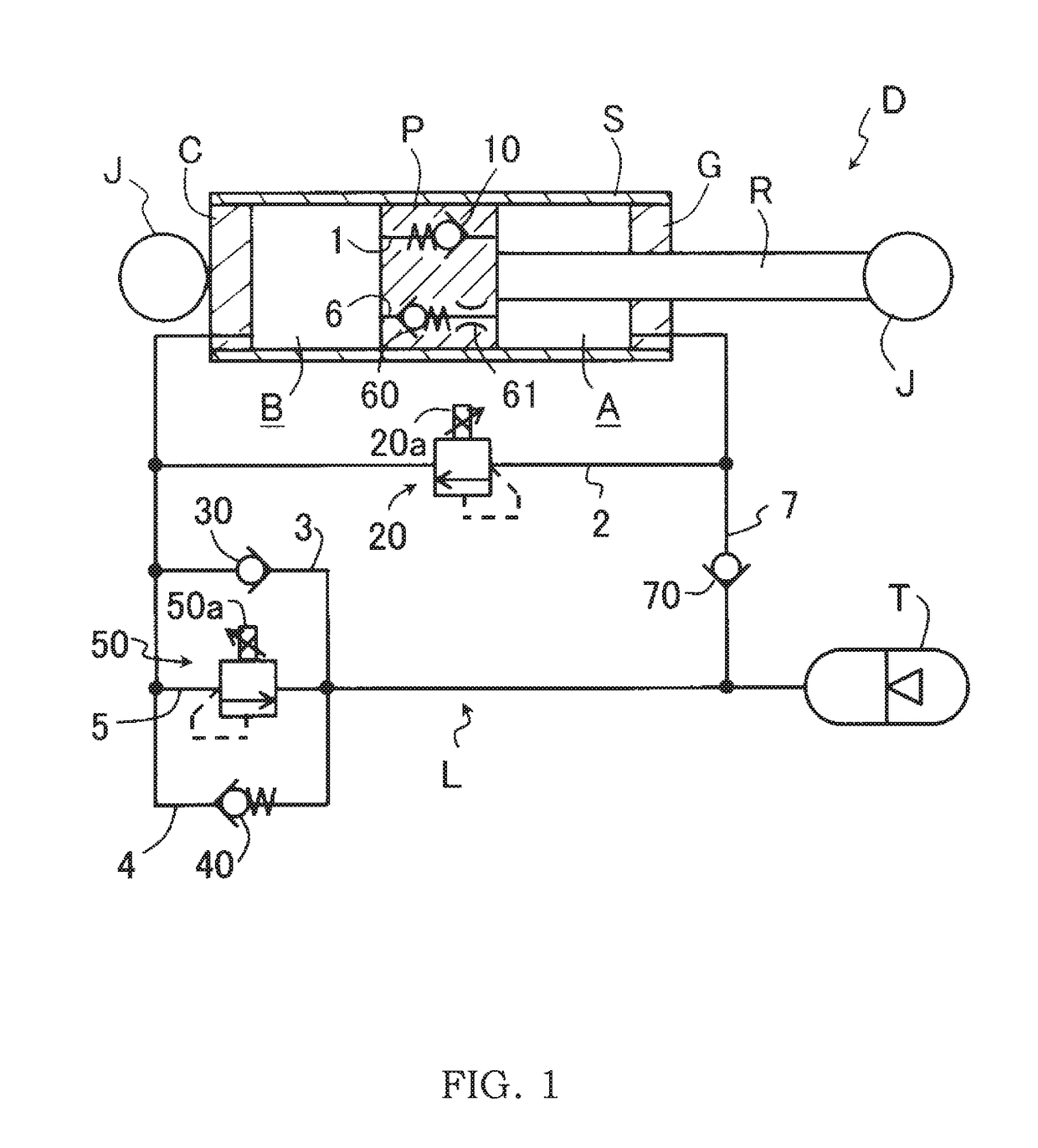

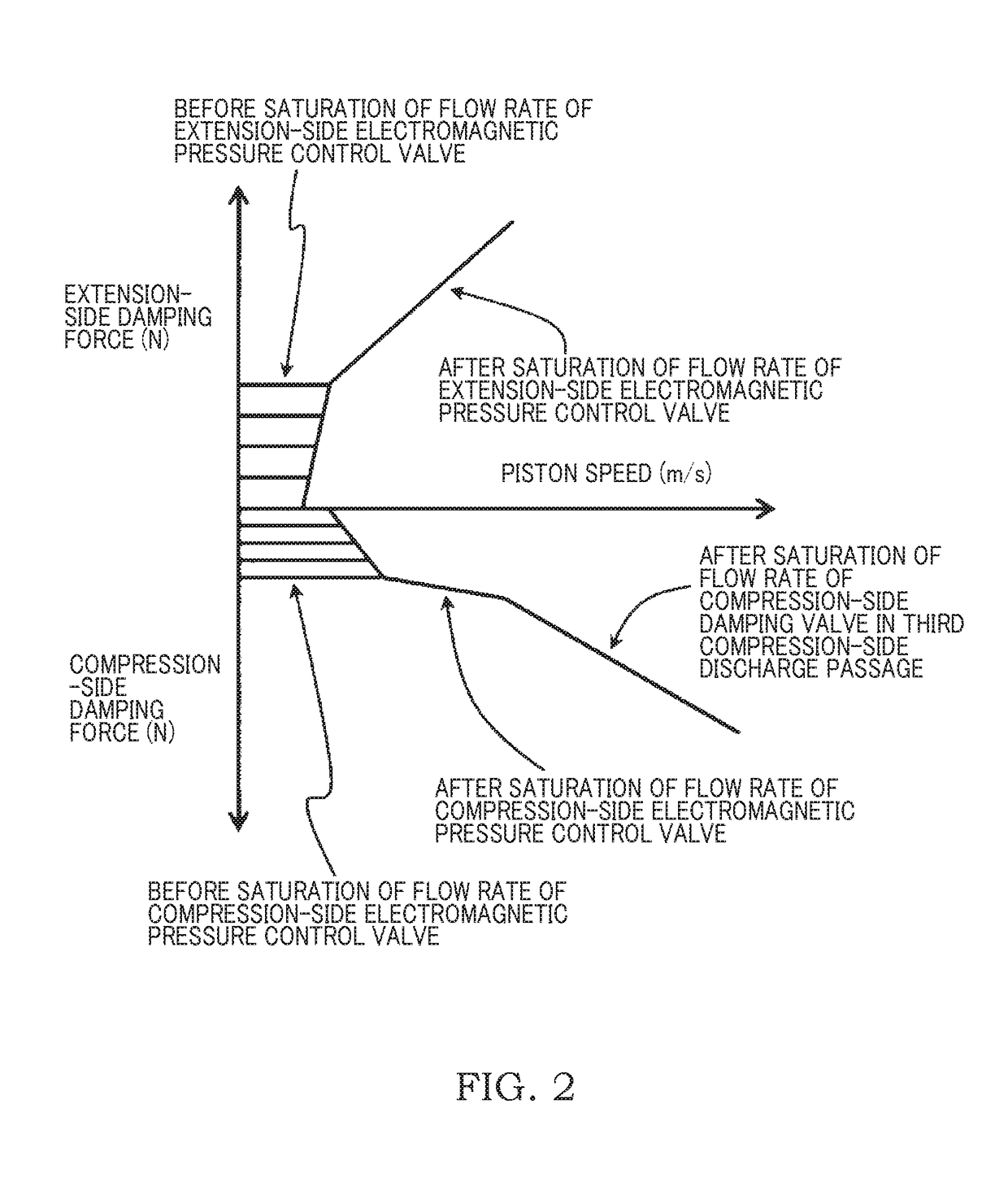

Shock absorber

ActiveUS9683625B2Reduce vehicle qualityQuality improvementSpringsSprings/dampers functional characteristicsWorking fluidEngineering

A shock absorber includes a piston joined to a piston rod that proceeds into and recedes from a cylinder, an extension-side chamber and a compression-side chamber that are separated from each other by the piston and have a working fluid reserved therein, first and second extension-side discharge passages in which the working fluid discharged from the extension-side chamber flows, an extension-side supply passage in which the working fluid to be supplied to the compression-side chamber flows, first and second compression-side discharge passages in which the working fluid discharged from the compression-side chamber flows, and a compression-side supply passage in which the working fluid to be supplied to the extension-side chamber flows. An extension-side damping valve and a compression-side damping valve are respectively provided in the first extension-side discharge passage and the first compression-side discharge passage. An extension-side electromagnetic pressure control valve and a compression-side electromagnetic pressure control valve, which are respectively provided in the second extension-side discharge passage and the second compression-side discharge passage, are set such that the openings thereof are maximized before the piston speed reaches a high-speed range.

Owner:KYB CORP

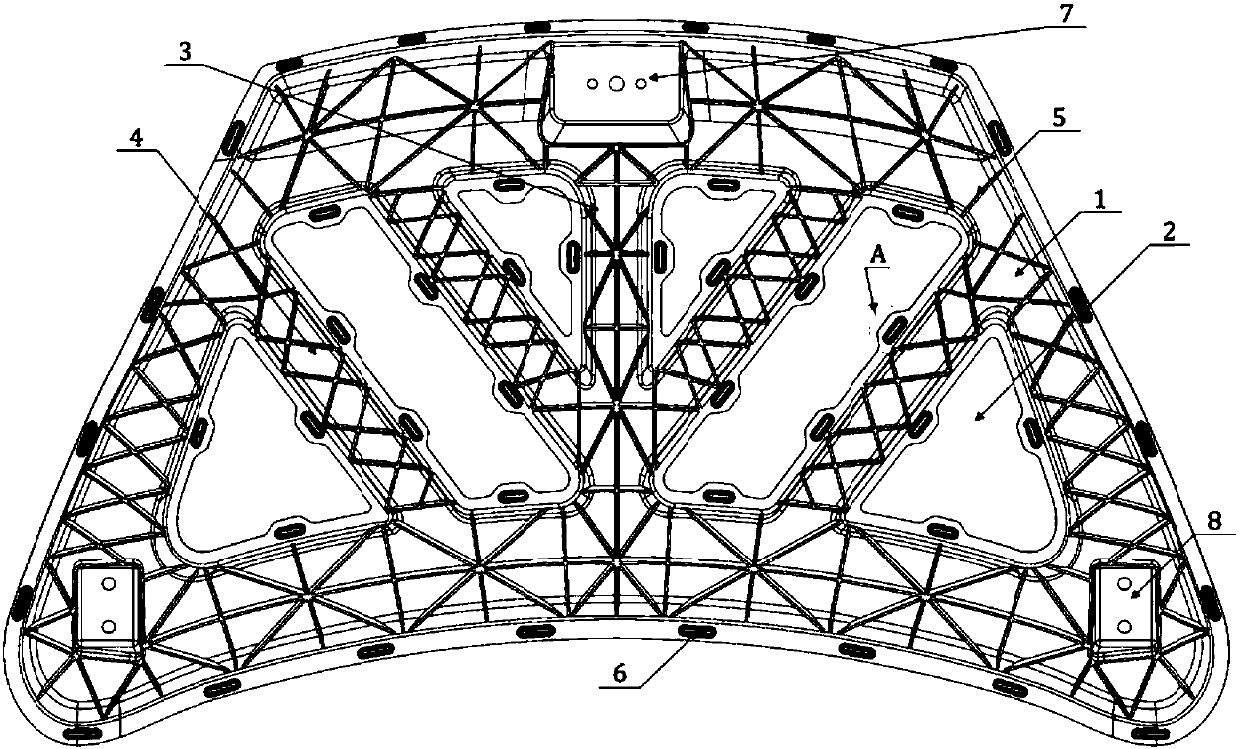

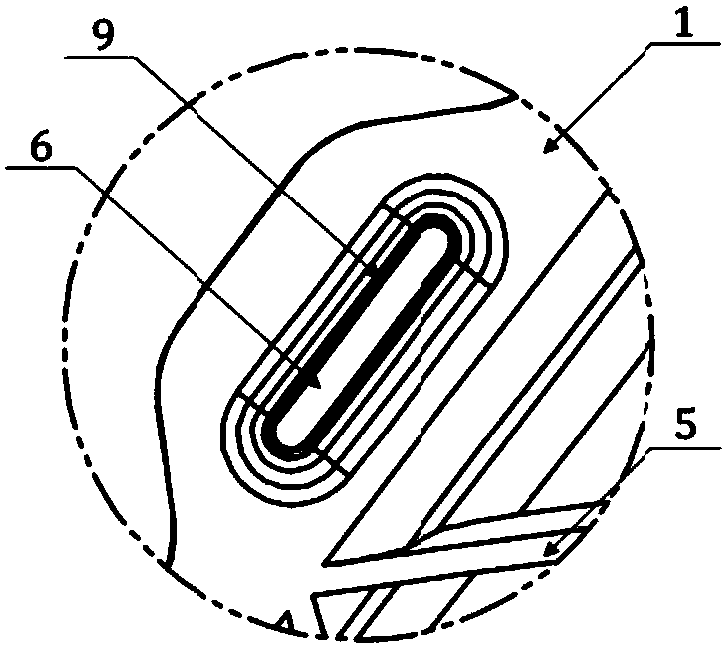

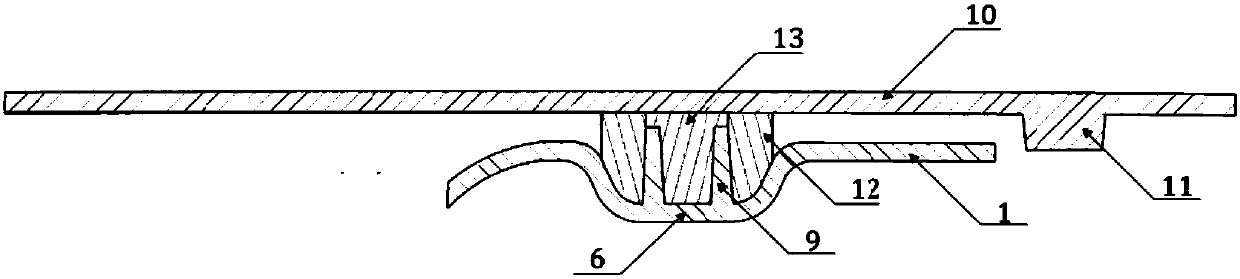

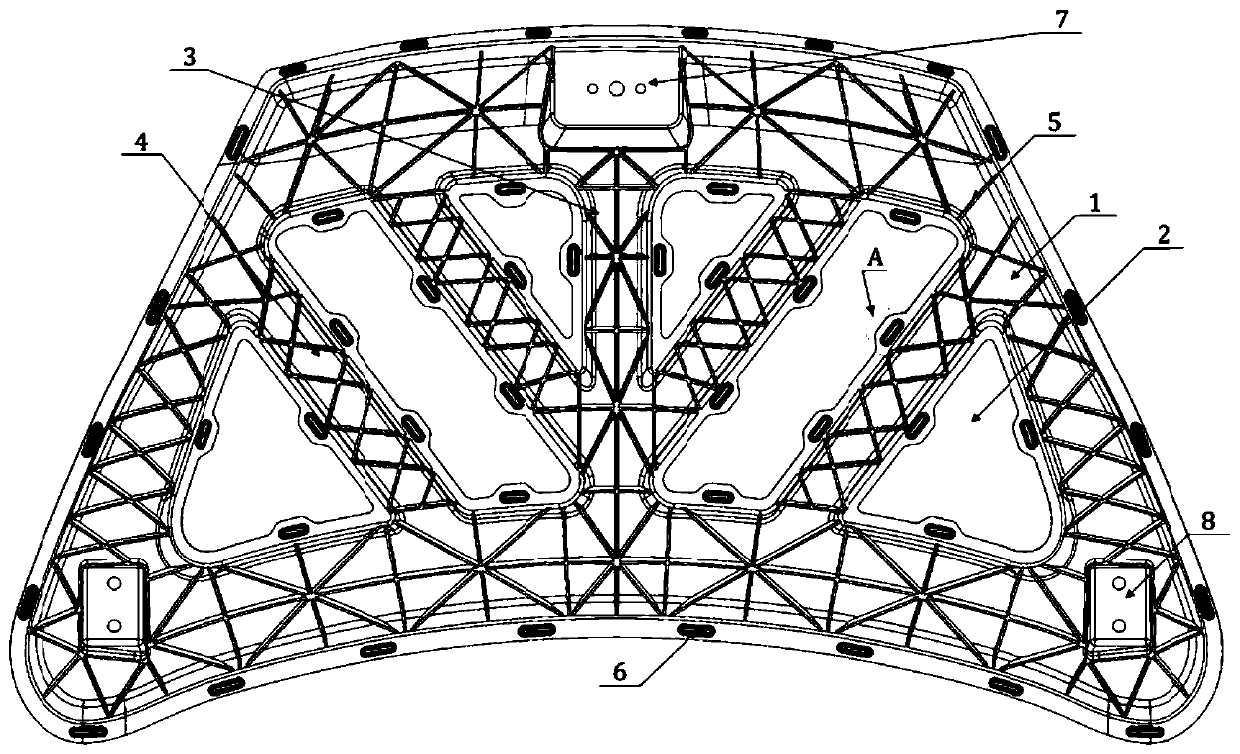

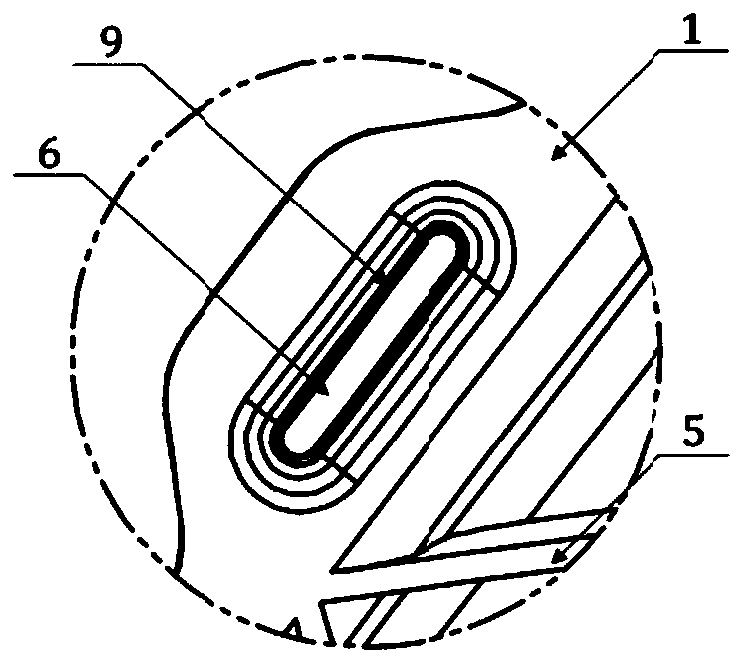

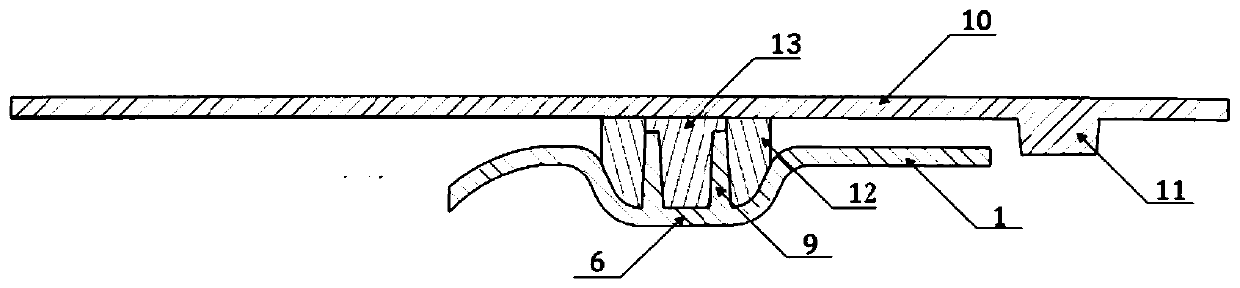

Composite engine hood inner panel of electric vehicle

ActiveCN107554620ALimit spacingGuaranteed thicknessSuperstructure subunitsStress concentrationAdhesive

The invention relates to a composite engine hood inner panel of an electric vehicle. An engine hood inner panel and an engine hood outer panel are connected in a gluing manner through an adhesive; theengine hood inner panel is provided with a flange; the gluing connection structure comprises a plurality of hoppers, stop blocks and a spill-proof block; the hoppers are respectively arranged on theflange of the engine hood inner panel; the stop blocks are arranged on the side near the outer panel, in the hoppers; the shape of each of the stop blocks is matched with that of the corresponding hopper; the stop blocks are higher than the plane of the inner panel; two kinds of adhesive with different properties can be separated by the stop blocks to achieve hybridization gluing; the spill-proofblock is located on the side near the inner panel, of the outer panel; the shape of the spill-proof block is determined according to the shape of the edge of the inner panel; the spill-proof block ishigher than the plane of the inner panel to prevent the adhesive form spilling; the composite-material engine hood inner panel disclosed by the invention is formed by adopting integrated injection molding of composites, and is low in the mold opening cost and high in the production efficiency; and through adoption of the hybridization connection, mechanical properties of different cohesive glue layers are reasonably utilized, the stress concentration at end heads is reduced, better adhesive properties are achieved, beautiful appearance of gluing is guaranteed, and the cost is saved.

Owner:GUANGXI AISHENG CHUANGZHI SCI & TECH CO LTD

An electric vehicle electromagnetic integrated energy-feeding suspension actuator and its control method

ActiveCN109808437BReasonable designSimple structureResilient suspensionsMagnetorheological fluidData acquisition

Owner:XIAN UNIV OF SCI & TECH

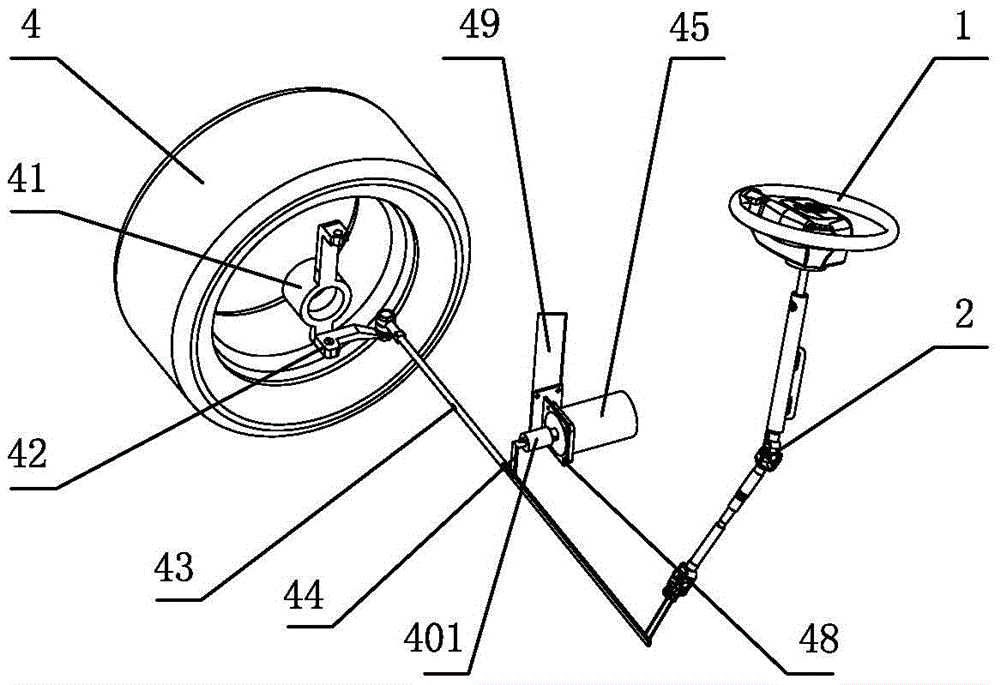

Electric steering system and electric steering control method of new energy automobile

InactiveCN103496394ASimple structureSave spaceSteering linkagesAutomatic steering controlSteering columnSteering wheel

The invention relates to steering systems and steering control methods of automobiles, in particular to an electric steering system and electric steering control method of a new energy electric automobile. The electric steering system of the new energy automobile is characterized by comprising an electric steering mechanical system and an electric steering control system; the electric steering mechanical system comprises a steering wheel, a steering column, a left steering wheel and a right steering wheel; the steering column, the left steering wheel and the right steering wheel are connected with the steering wheel; a damping feedback motor is connected to the steering column. The structure of an automobile front axle is simplified, and performance of the steering system of the new energy automobile is optimized.

Owner:江苏英田专用车制造有限公司

Mixed arm type overhead working truck

The invention discloses a mixed arm type overhead working truck. The mixed arm type overhead working truck comprises hydraulic supporting legs, an automobile chassis, a rotary table, a low variable-amplitude hydraulic cylinder, an upper variable-amplitude hydraulic cylinder, a lower main arm, an upper main arm, a lower telescopic arm, an uppper telescopic arm, a working platform, a working platform pedal and a working platform leveling mechanism, wherein the hydraulic supporting legs are arranged on the bottom of the automobile chassis; the rotary table is arranged on the automobile chassis; and the lower main beam is hinged on the rotary table. The mixed arm type overhead working truck is characterized in that the section of the lower telescopic arm is octahedral, and the section of the upper telescopic arm is hexagonal. According to the mixed arm type overhead working truck disclosed by the invention, upper and lower telescopic arms with different sections are adopted, and reinforcing ribs are mounted on the lower telescopic arm and the upper telescopic arm, so that strength, rigidity and stability of the overhead working truck with relatively high operating height (50m-110m) further can be guaranteed, and therefore, the performance of the whole truck is improved. Meanwhile, a weight reducing hole in the lower telescopic arm can reduce dead load of an arm rest of the overheadworking truck, reduces mass of the whole truck, and reduces production and operation cost.

Owner:刘江

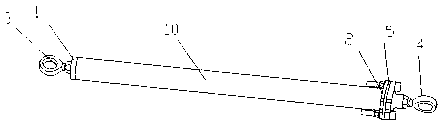

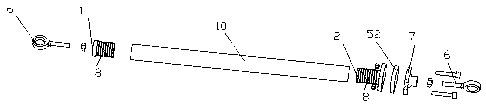

Novel carbon fiber steering tie rod mechanism and manufacturing method thereof

PendingCN107914769AMeet drivingReduce vehicle qualitySteering linkagesAssembly machinesFiberCarbon fibers

The invention discloses a novel carbon fiber steering tie rod mechanism. The novel carbon fiber steering tie rod mechanism is characterized by comprising a rod body, wherein the rod body is a hollow rod body prepared from a carbon fiber material, a front connector and a rear connector are arranged at two ends of the hollow rod body, the front connector, the rear connector and the hollow rod body are fixedly connected, the front connector is provided with a connecting assembly I connected with a steering gear, the rear connector is provided with a connecting assembly II connected with a steering knuckle, and a travel adjusting mechanism is also arranged between the rear connector and the connecting assembly II connected with the rear connector. The novel carbon fiber steering tie rod mechanism only comprises the hollow rod body, the front connector and the rear connector, is simple in structure and convenient to manufacture, meanwhile the hollow rod body is made from the carbon fiber material, the front connector and the rear connector are aluminum products, and the weight of the tie rod mechanism is reduced on the premise that the strength and safety performance of a vehicle are ensured. In addition, the novel carbon fiber steering tie rod mechanism is simple in manufacturing, and industrial production is facilitated.

Owner:LAUNCH DESIGN INC LTD

Automobile traveling mechanism with wheel hub comprehensively drive and turning

InactiveCN101648573BSteering precisionImprove efficiencyMechanical steering gearsElectrical steeringVehicle frameCoil spring

Owner:JILIN UNIV

Lithium battery system replacing lead-acid electric vehicle battery system and manufacturing method thereof

ActiveCN104868198BReduce vehicle qualityLightweight reductionSecondary cellsCell component detailsElectric-vehicle batteryAutomotive battery

The invention relates to a lithium battery system replacing a lead-acid electric vehicle battery system and a manufacturing method thereof, including a battery pack shell, a battery module, a bracket, a BMS and electrical components, wherein the battery pack shell includes an upper shell and a lower shell, The upper case and the lower case can be closed and connected; the battery module is composed of lithium batteries connected in series and parallel, which are fixed on the lower case of the battery pack through a bracket; the BMS is installed on the bracket; design position. The manufacturing method includes the following steps: (1) processing the shell of the battery pack and the internal bracket; (2) assembling lithium batteries in series and parallel into a module by using connecting cables and connecting copper bars; (3) lowering the shell of the discharged battery pack of the module, And install the bracket to fix it; (4) Install the relevant electrical components to the design of the battery case; (5) Install the BMS on the bracket; (6) Close the upper case of the battery pack. The replacement scheme of the present invention can reduce the use of lead-acid batteries and reduce the risk of environmental pollution; since lithium batteries are used to replace lead-acid batteries, a low-temperature charging and heating system is added to improve the low-temperature discharge capacity and low-temperature charging performance of the battery system.

Owner:奇瑞新能源汽车股份有限公司

Arm support link mechanism, folding type arm support and concrete pump vehicle

ActiveCN101435267BSimple structural designSimple structureBuilding material handlingControl engineeringStructural engineering

The invention discloses an arm frame linkage mechanism, which comprises a first arm frame, a second arm frame, a first linkage, a second linkage, and an oil cylinder, wherein the firs arm frame is hinged with the second arm frame, and one end of the oil cylinder is hinged at the hinge point of the first arm frame and the second arm frame; the head ends of the first linkage, the second linkage arerespectively hinged on the first arm frame and the second arm frame; and the tail ends of the first linkage and the second linkage are respectively hinged on the oil cylinder. Because one end of the oil cylinder can be vacant, the arm frames need no oil cylinder seat, and the oil cylinder seat mounting problem can not be considered, the structure design of the arm frames can be greatly simplified; and the linkages adopt simple two hole type, so the structure is simple, and the weight is lighter. For the oil cylinder seat is omitted, not only the latent fault initiated by the tearing of the oil cylinder seat is avoided and the equipment fault rate is reduced, but also the whole vehicle weight of the equipment can be reduced. On the base, the invention also discloses a foldable arm frame and a concrete pump truck.

Owner:SANY AUTOMOBILE MFG CO LTD

Trailer traction saddle welding process method

PendingCN113814671AGuaranteed sizeQuality assuranceTractor-trailer combinationsNumerical controlSlide plate

The invention discloses a trailer traction saddle welding process method and relates to the technical field of welding. In order to solve the problems that after the trailer traction saddle is welded through an existing welding method, a sliding plate of the trailer traction saddle is seriously deformed, the qualified rate of finished products is lower due to the fact that errors exist in the length and the width of a blank caused by adopting manual operation during blanking in the initial stage, a numerical control cutting machine is adopted for the blanking, a plate bending machine is used for bending a cut plate, three kinds of reinforcing ribs are manufactured, the size and quality of a reinforcing groove are guaranteed, it is guaranteed that assembly gaps of welding joints are uniform and consistent in the subsequent assembly process, and the welding deformation amount is reduced; secondly, leftover materials are used for the blanking and bending manufacturing, so that the production cost of the products is reduced, and the total weight of a whole trailer is further reduced, and by adopting the welding mode, the phenomenon of serious deformation of the sliding plate after welding operation is prevented, so that the qualified rate of the finished products is improved, and the working efficiency is improved. The method is suitable for the technical field of welding.

Owner:哈尔滨建成北方专用车有限公司

An electric vehicle composite material hair cover inner panel

ActiveCN107554620BReduce vehicle qualitySimplify component compositionSuperstructure subunitsAdhesiveElectric vehicle

Owner:GUANGXI AISHENG CHUANGZHI SCI & TECH CO LTD

Semiconductor Laser and Laser Radar Device Having the Semiconductor Laser

PendingUS20220311217A1Reduce vehicle qualityQuality improvementOptical wave guidanceLaser detailsQuantum dotLaser light

A semiconductor laser includes an active layer which emits laser light and cladding layers being formed so as to sandwich the active layer. The active layer includes a quantum dot layer including a plurality of quantum dots, which respectively confine movements of carriers in the three-dimensional directions. The laser radar device includes a light projection part which projects laser light and a light receiving part which receives reflected light of the laser light. The light projection part includes the semiconductor laser and a scanner which reflects the laser light, emitted from the semiconductor laser, to form a scanning laser light.

Owner:SAE MAGNETICS (HK) LTD

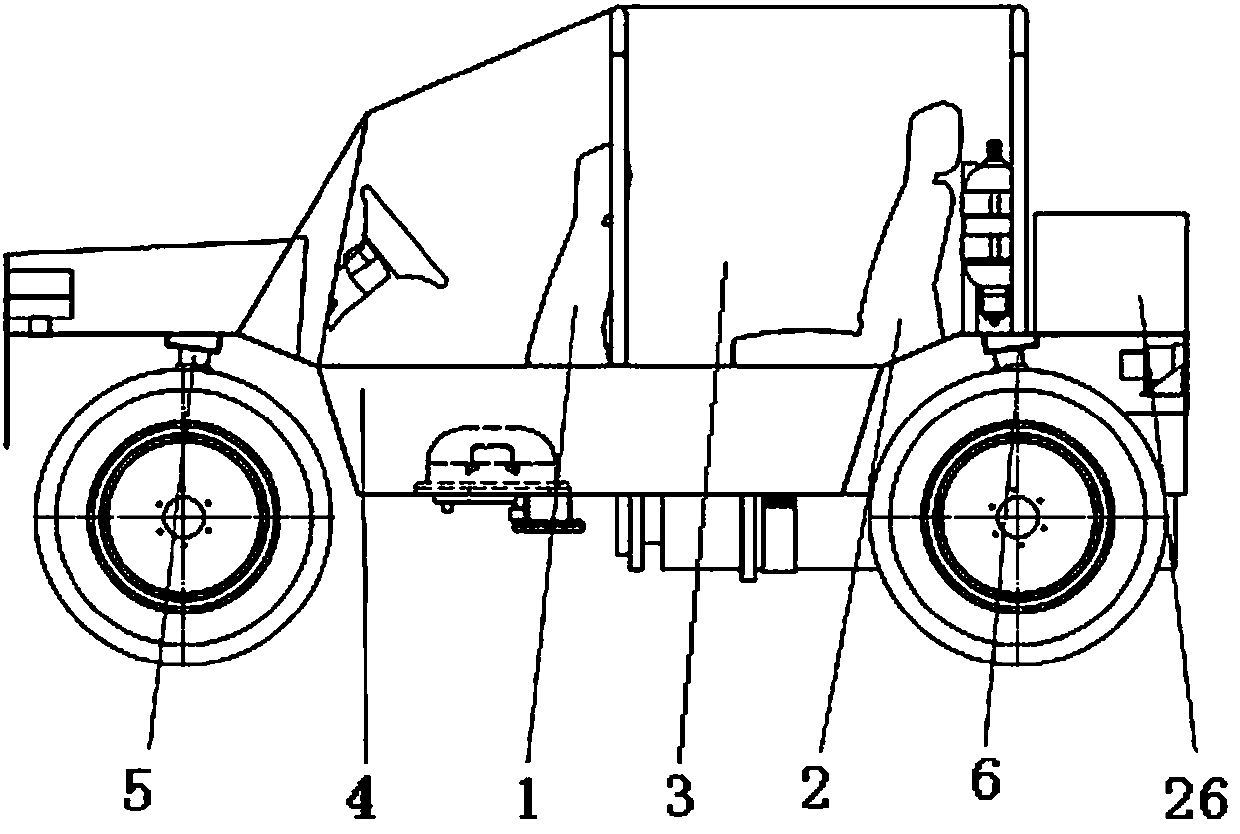

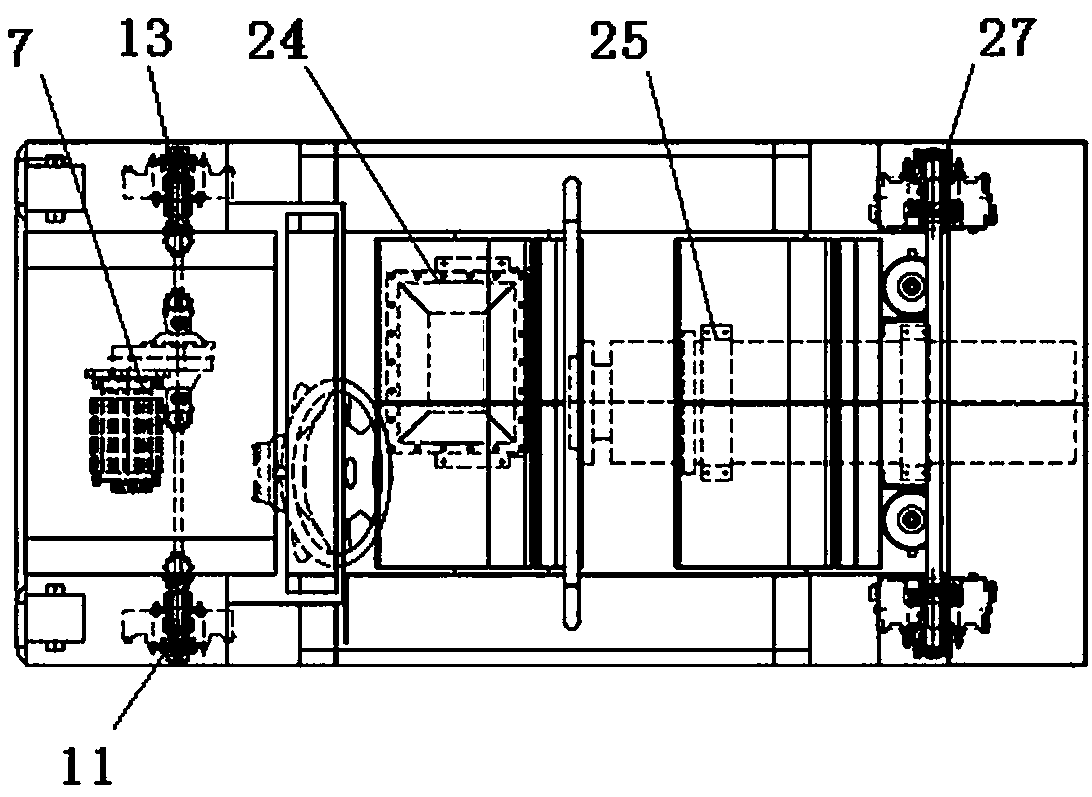

A light explosion-proof electric vehicle for mining

ActiveCN105346384BIncrease mileageReduce vehicle qualityBraking element arrangementsElectric propulsion mountingElectric vehiclePollution

The invention belongs to the field of auxiliary transportation devices for underground coal mines and particularly relates to a light mine explosion-proof electric vehicle. The light mine explosion-proof electric vehicle aims at solving the problem that no small flexible pollution-free explosion-proof electric vehicle for an underground coal mine exists at preset. A chassis body is of an integrated structure formed by welding steel plates and profile steel in an overlap joint manner. A motor transmission system comprises an explosion-proof motor, a differential speed reduction gearbox, a short transmission half shaft of a spherical cage structure, a long transmission half shaft of a spherical cage structure, a front left wet-type multi-disc brake and a front right wet-type multi-disc brake. A front independent suspension system structurally comprises a left shock absorber, a left swing arm and a left stabilizing rod and a rear independent suspension system structurally comprises a right shock absorber, a right swing arm and a right stabilizing rod. The left angle of elevation and the right angle of elevation are provided with shock absorber connection points, stabilizing rod connection points and swing arm connection points respectively. On the premise that the structural strength requirement is met, the lightweight design is adopted, the mass of the whole vehicle is reduced as much as possible, and the light mine explosion-proof electric vehicle has the beneficial effects of being low in mass, small in shape size, compact in structure, flexible and efficient in mechanic operation, free of pollution and the like and is mainly used for the fields of rescue, overhauling, inspection and the like of the underground coal mines.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

A new energy vehicle electric steering control method

InactiveCN103496394BSimple structureSave spaceSteering linkagesAutomatic steering controlSteering wheelSteering column

Owner:江苏英田专用车制造有限公司

electric car

ActiveCN103144530BSimple structureEasy to processMotor depositionMagnetic holding devicesEngineeringElectric cars

The invention relates to an electric vehicle which comprises a vehicle body, a plurality of magnetic electric wheels, a plurality of third permanent magnet groups, a plurality of control windings and a plurality of second steering windings, wherein the magnetic electric wheels are arranged at the lower part of the vehicle body; each magnetic electric wheel comprises a wheel body, a first permanent magnet arranged at the center of the wheel body, and two second permanent magnets at both ends of the wheel body in the transverse direction; the second permanent magnets towards the inside of he vehicle body are provided with first steering permanent magnets; each third permanent magnet group comprises two third permanent magnets with the same magnetism with the first permanent magnet; the control windings correspond to the magnetic electric wheels; variable currents are conducted inside the control windings to generate alternately changing magnetic fields matched with the second permanent magnets; the second steering windings correspond to the first steering permanent magnets; and variable currents are conducted inside the second steering windings to generate magnetic fields with different intensities and enable the second steering windings to be matched with the first steering permanent magnets. According to the electric vehicle disclosed by the invention, the vehicle body is completely suspended above the magnetic electric wheels, electric energy is converted into the magnetic fields, the power source has no pollution, and the electric vehicle has high utilization rate of energy, a simple structure and high traveling safety.

Owner:BEIQI FOTON MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com