Lithium battery system capable of replacing lead-acid electric vehicle battery system and manufacturing method thereof

A technology for electric vehicles and battery systems, applied in the direction of batteries, secondary batteries, battery pack components, etc., can solve the problems of low specific energy of lead-acid batteries, difficult use and recycling, short driving mileage, etc., to increase the capacity of the battery system, The effect of increasing the service life and increasing the life of the battery system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

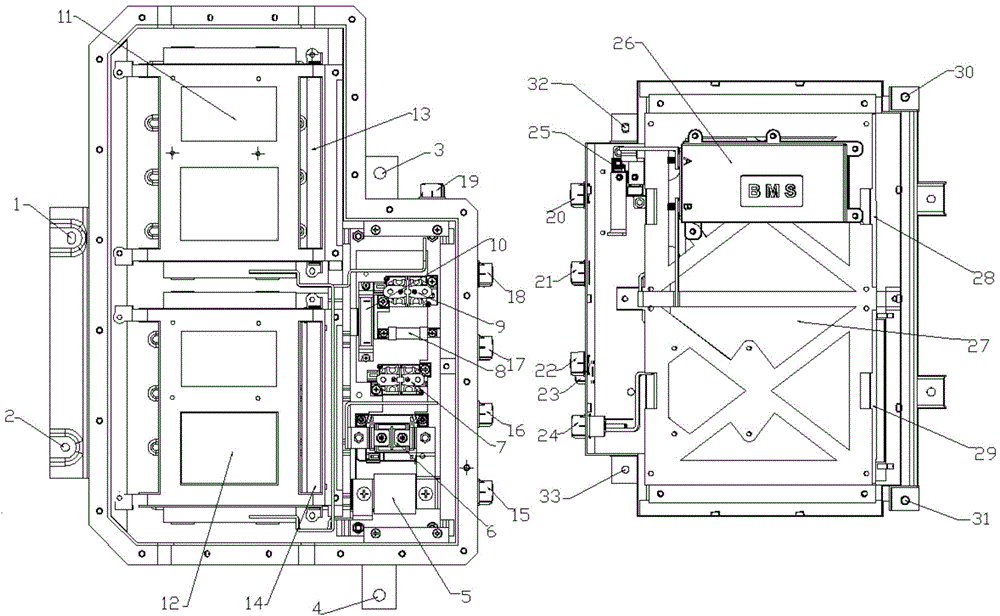

[0057] The present invention will be described in detail below according to the accompanying drawings, which is a preferred embodiment among various implementations of the present invention.

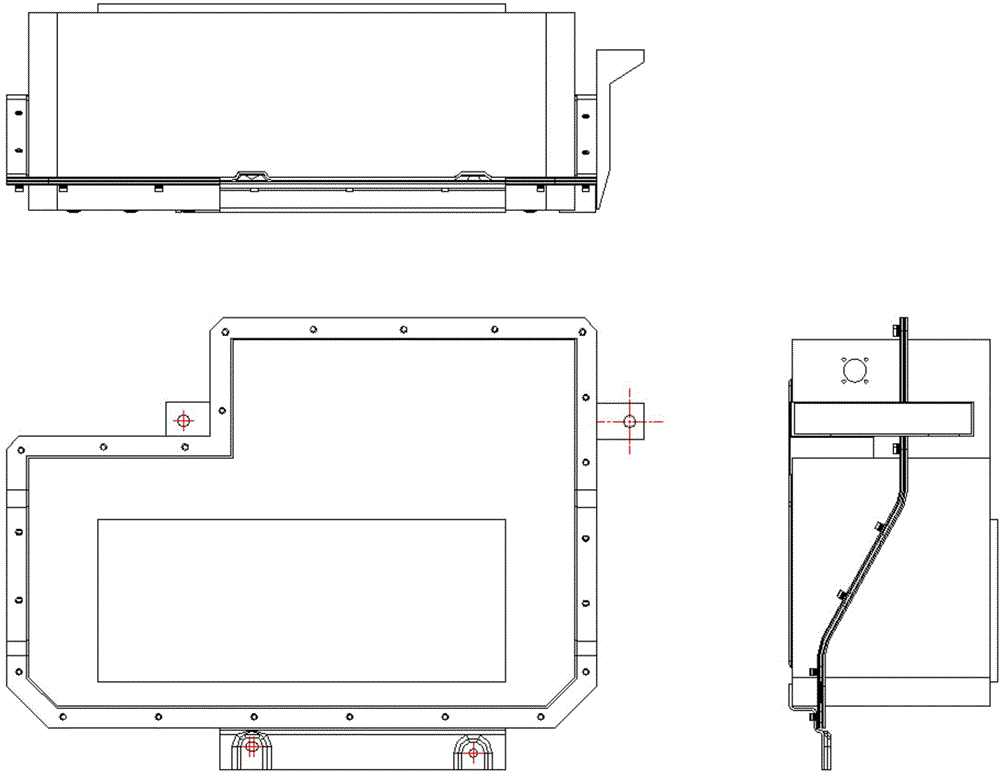

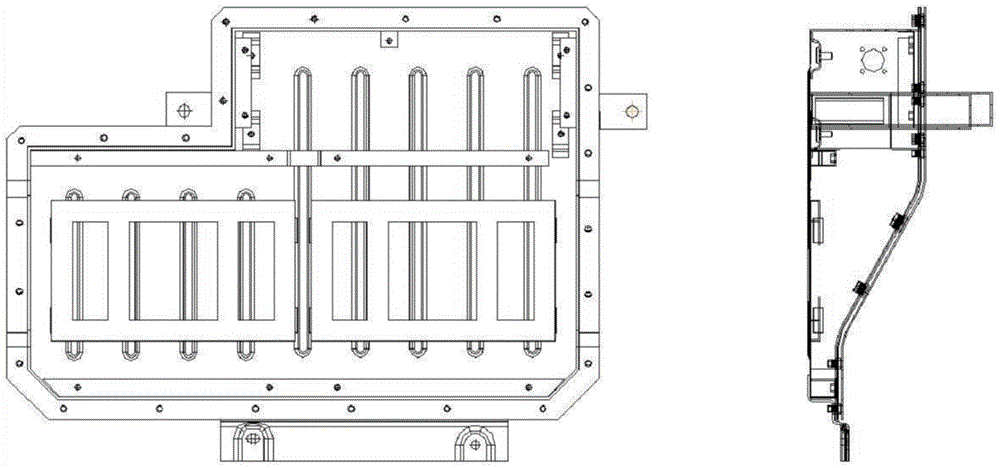

[0058] Combine below Figure 1-12 The examples shown are specific illustrations of the invention.

[0059] Step 1: Process the lower shell of the left battery pack shell ( image 3 ), the upper cover of the left battery pack ( Figure 4 ), battery module fixing bracket inside the left battery pack ( Figure 5 ) 2 pieces, the lower shell of the right battery pack ( Figure 7 ), the upper cover of the right battery pack ( Figure 8 ), battery module fixing bracket inside the battery pack ( Figure 9 ). ① For the lower shell of the left battery pack shell ( image 3 ) to expand the drawing, select a steel plate of a certain thickness, and press the selected steel plate according to the expanded drawing (manual samples can be processed by wire cutting), and the stamped parts have a low-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com