Arm support link mechanism, folding type arm support and concrete pump vehicle

A technology of a linkage mechanism and a boom is applied in the field of concrete pump trucks to achieve the effect of simplifying the structure design, avoiding potential failures and simplifying the structure form.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

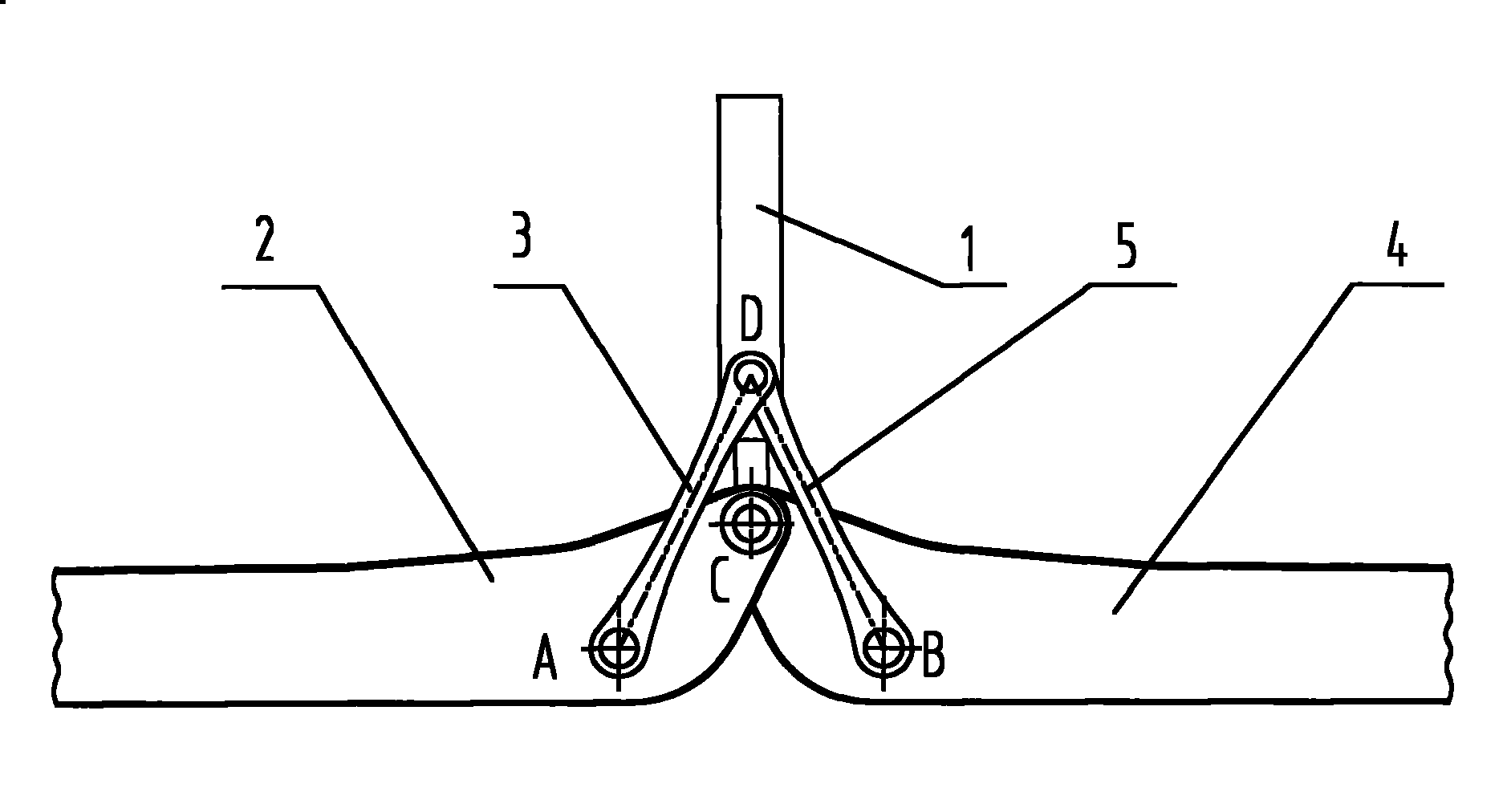

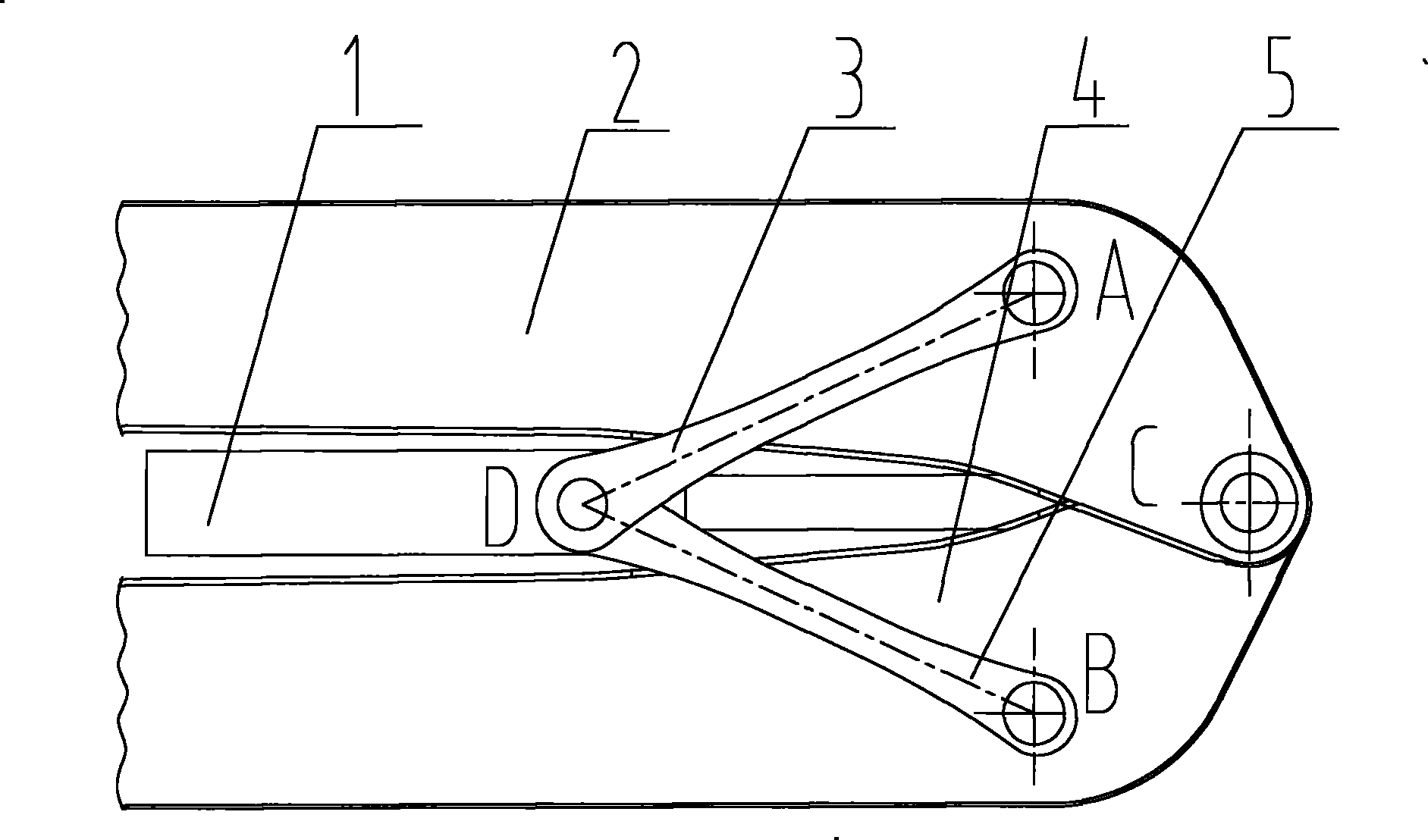

[0023] The basic idea of the present invention is that one end of the oil cylinder is connected to the hinge point of the two booms, the head ends of the two connecting rods are respectively hinged on the corresponding booms, and the tail ends are respectively hinged on the oil cylinder; Realize the expansion and retraction of the boom.

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

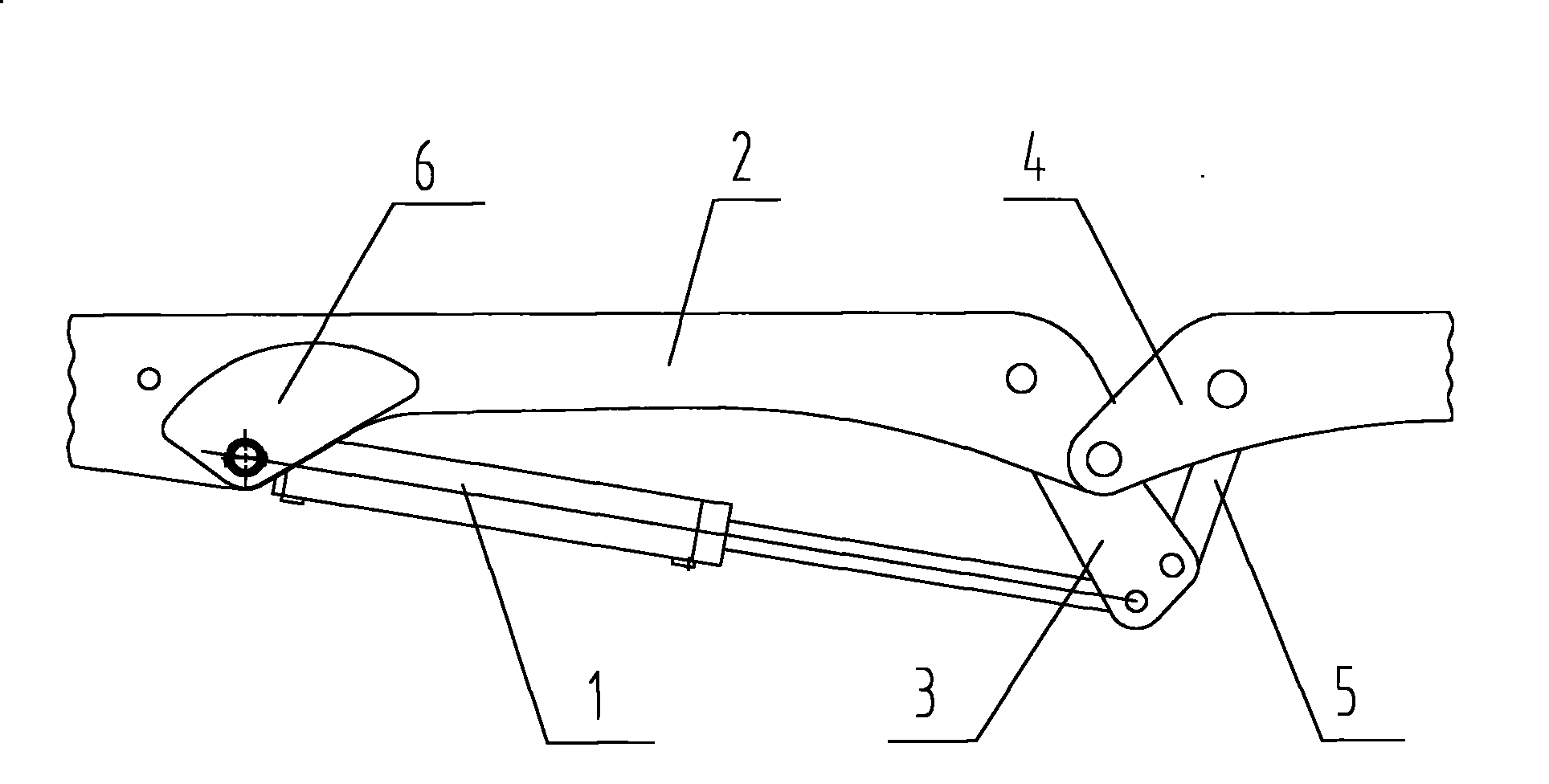

[0025] See also figure 2 , image 3 ,in: figure 2 It is a schematic diagram of a preferred embodiment of the boom linkage mechanism of the present invention when it is deployed; image 3 yes figure 2 A schematic diagram of the boom link mechanism in a folded state. In this embodiment, the boom link mechanism includes a first boom 2, a second boom 4, a first connecting rod 2, a second connecting rod 5 and an oil cylinder 1, wherein:

[0026] The first jib 2 is hinged to the second jib 4 at a hinge point C; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com