Full-membrane micro-concentrated water nanofiltration machine

A concentrated water and nanofiltration technology, applied in the field of nanofiltration machines, can solve the problems of reduced filter replacement frequency, easy clogging of pretreatment filter elements, and bacteria breeding in storage buckets, so as to reduce the discharge ratio of concentrated water, increase the recovery rate of pure water, Water saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

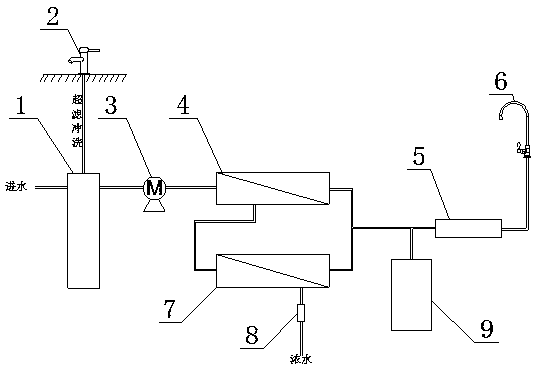

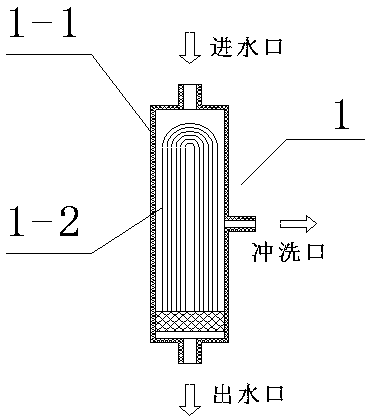

[0023] Refer to attached figure 1 , 2 , the full-membrane micro-concentrated water nanofiltration machine includes ultrafiltration filter element 1, vegetable sink faucet 2, booster pump 3, first-stage nanofiltration membrane 4, second-stage nanofiltration membrane 7, post-installed activated carbon filter element 5, water purification Faucet 6, concentrated water proportional device 8, water storage bucket 9.

[0024] The ultrafiltration filter element 1 is provided with a water inlet, and the water inlet is connected to the tap water pipeline through a water inlet pipe. The water outlet is connected to the water inlet of the booster pump 3 through a pipeline. The booster pump 3 is provided with a water outlet, and the water outlet is connected to the water inlet of the first-stage nanofiltration membrane 4 through a pipeline. Inlet, the first-stage nanofiltration membrane 4 is provided with a concentrated water outlet, and the concentrated water outlet is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com