Miniaturized and compact duplexer based on thin film integrated passive device technology

An integrated passive device, compact technology, applied in waveguide-type devices, electrical components, circuits, etc., can solve the problems of large size and unstable performance of duplexers, and achieve improved performance, high quality factor, and high precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

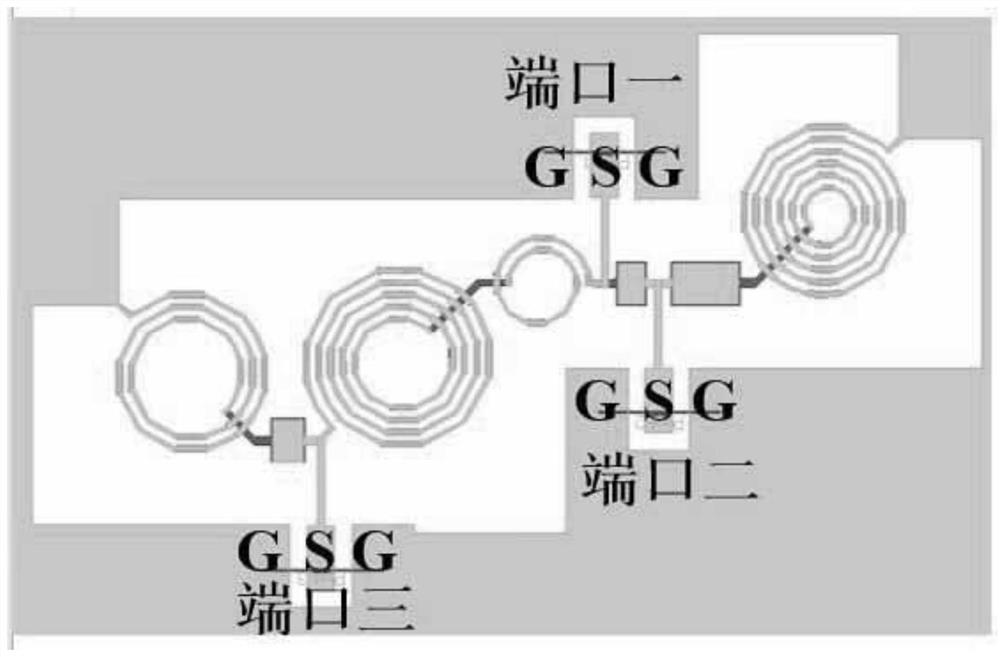

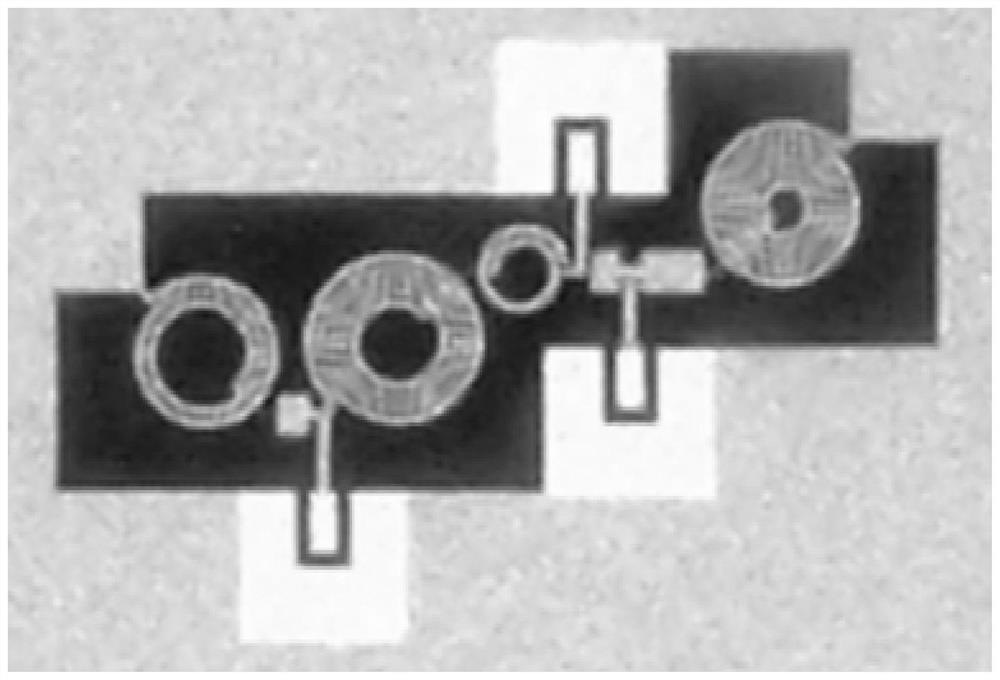

[0021] Embodiment 1: The miniaturized and compact duplexer based on thin-film integrated passive device technology in this embodiment includes a high-pass filter and a low-pass filter, the high-pass filter is coupled to signal port one P1 and signal port two P2, and the low-pass filter The filter is coupled to the signal port one P1 and the signal port three P3, where the high-pass filter is composed of the second capacitor C 2 Parallel first capacitance inductance resonant circuit (loop) is formed, and described first capacitance inductance resonant circuit is made of No. 1 capacitance C 1 and the No. 1 inductor L 1 series; wherein the low-pass filter is made up of two series inductors connected in parallel with the second capacitor-inductance resonant circuit (loop), and the two series inductors are composed of the second inductor L 2 and No. 4 inductance L 4 series, the second capacitor inductance resonant circuit consists of the third capacitor C 3 and No. 3 inductance ...

specific Embodiment approach 2

[0024] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the inductance element in the high-pass filter and the low-pass filter is a spiral inductor, and the capacitive element in the high-pass filter and the low-pass filter is a MIM (metal-medium - metal) type capacitors.

specific Embodiment approach 3

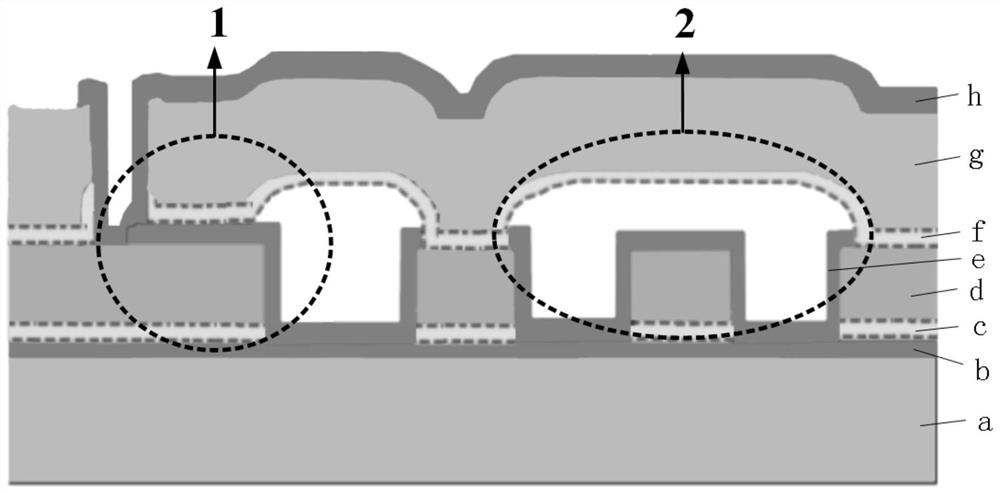

[0025] Specific Embodiment Three: In this embodiment, the preparation method of a miniaturized and compact duplexer based on thin film integrated passive device technology is implemented according to the following steps:

[0026] 1. Cleaning and polishing the surface of the substrate a to obtain a clean substrate;

[0027] 2. Depositing the first SiNx layer b on the clean substrate by plasma-enhanced chemical vapor deposition;

[0028] 3. Sputtering and depositing the first seed metal layer c on the surface of the first SiNx layer b, and then covering the wafer with a photomask, using photoresist to form a pattern of the bottom metal according to the circuit structure of a broadband miniaturized and compact duplexer, The bottom metal layer d is formed by an electroplating process, and the bottom metal layer d is used as the bottom metal of the MIM capacitor and the spiral metal of the spiral inductor, and the photoresist is removed after electroplating and the first seed metal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com