Head oscillating structure of warmer

A technology of a heater and a rotating part is applied in the field of the transformation of the shaking head structure, which can solve the problems of difficult to pass 750,000 shaking shaking tests, low assembly efficiency, and short shaking head life, and achieve a simple and compact appearance, improve assembly efficiency, and save space. The effect of size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

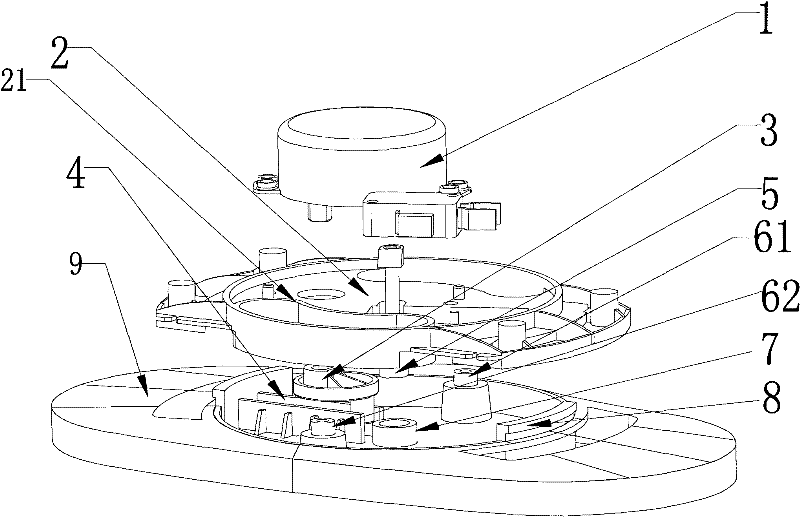

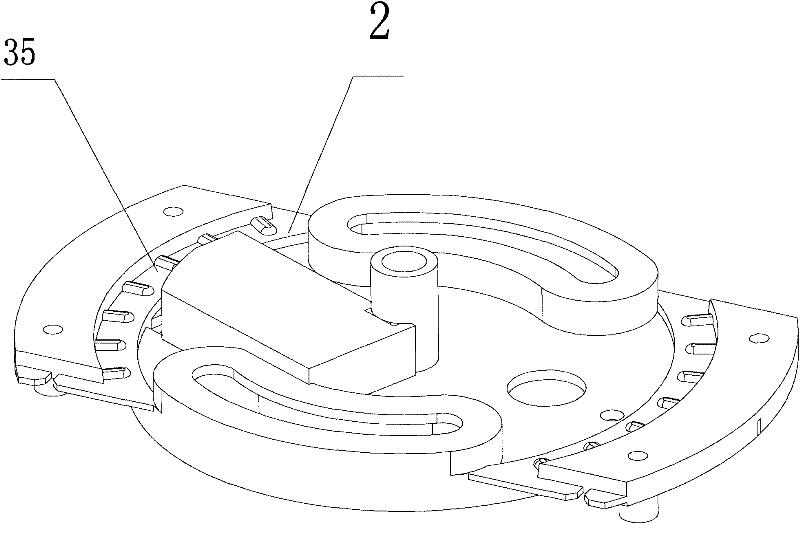

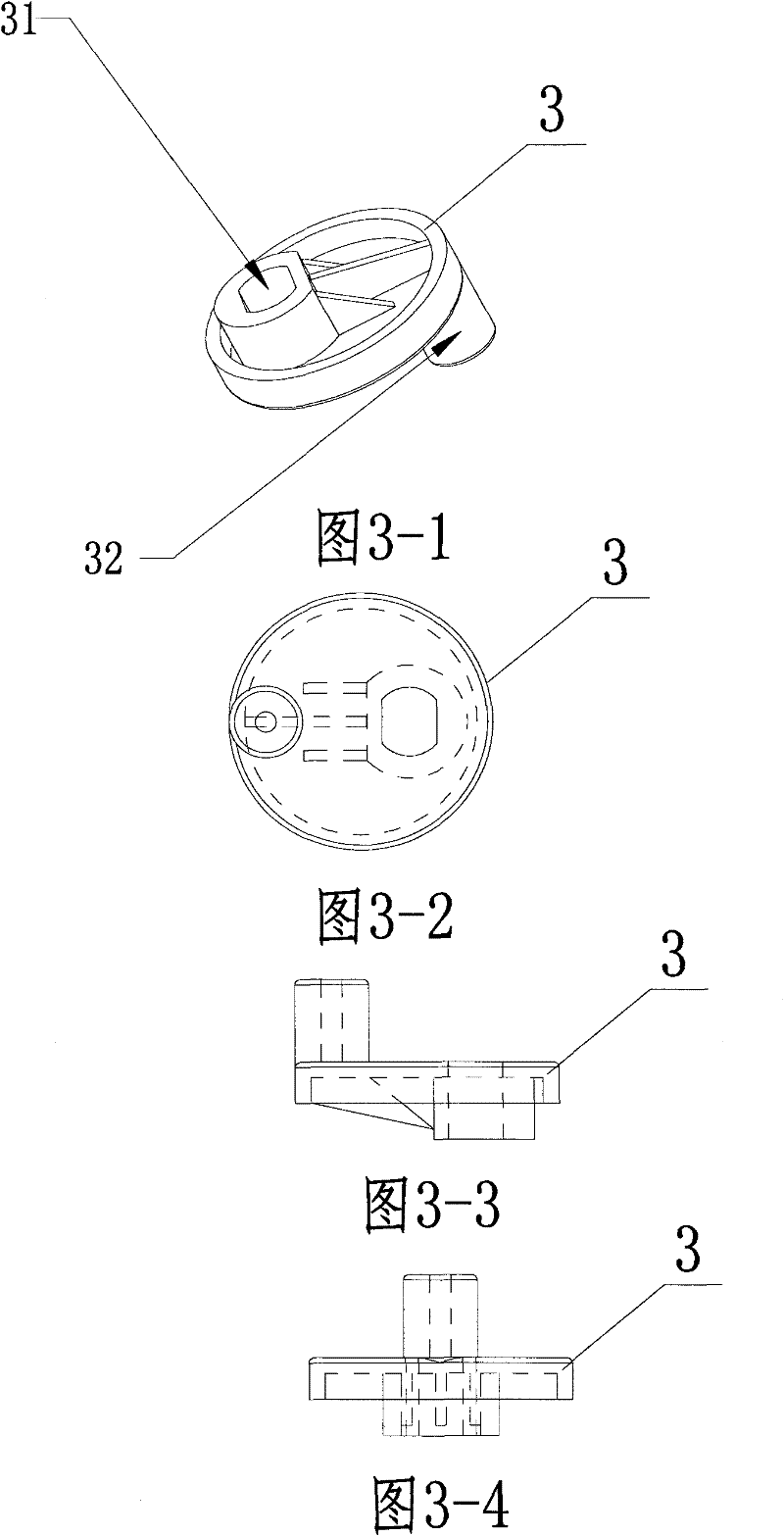

[0018] The structural schematic diagram of the present invention is as follows figure 1 , 2 As shown, including heater base 9 and rotating part 2, drive cam 3, drive motor 1, wherein drive cam 3 is placed between heater base 9 and rotating part 2, drive motor 1 is placed on top of rotating part 2, The output shaft of the driving motor 1 is inserted into the mounting hole 31 of the driving cam 3 through the rotating part 2 , and the driving shaft 32 of the driving cam 3 is placed in the slideway 4 provided on the base 9 . The sliding positioning columns 61 and 62 are installed in the rotating slideway 21 provided by the rotating part 2, and the rotating center shaft 5 provided on the rotating part 2 is sleeved on the rotating center sleeve 7 set on the base 9. The center sleeves 7 cooperate with each other to realize the rotational movement. In this embodiment, the rotation center shaft 5 and the rotation center sleeve 7 are hollow tubes, and the drive motor 1 is a synchronou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com