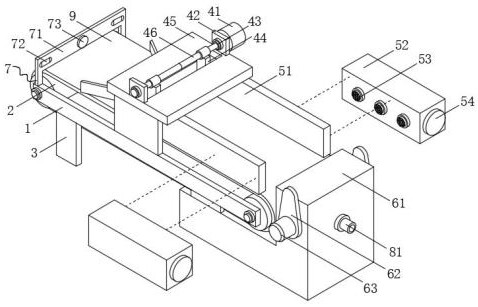

Industrial workshop assembly line conveying equipment based on automatic deviation rectifying mechanism

A technology of automatic deviation correction and conveying equipment, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc. It can solve the problems of parts falling, poor subsequent processing of parts, and influence, so as to avoid aging and remove impurities and stain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

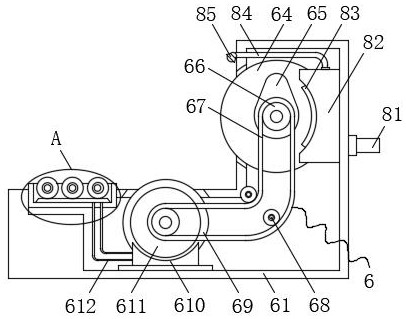

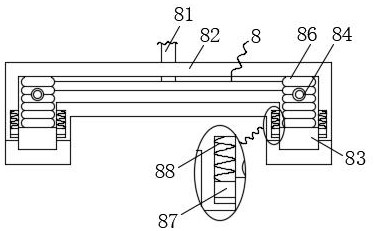

[0045] The specific embodiment is: when the second motor 63 works, it can drive the first cam 62 to rotate, the first cam 62 can squeeze the pressure plate 54, and the pressure plate 54 moves to the left to form a squeeze on the air bag 55. At this time, the air in the air bag 55 The effect of blowing dust on parts is achieved by spraying from multiple nozzles 53. By setting the insertion rod 56, the rod groove and the first spring 57, the insertion rod 56 can move freely in the rod groove, so that the pressing plate 54 can be stably moved along the track. Move, and when the pressing plate 54 is no longer squeezed, the first spring 57 pushes the plunger 56 through its own elastic force to allow the pressing plate 54 to move to the initial position to the right, preparing for the next pressing plate 54 to be squeezed and blow dust.

[0046] The lower surface of the side plate 1 is fixedly connected with a cleaning mechanism 6, and the cleaning mechanism 6 includes a brush roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com