Tubular spiral conveyor for kitchen garbage

A screw conveyor and kitchen waste technology, applied in the direction of conveyor objects, garbage collection, application, etc., can solve problems such as difficult discharge, inconvenient fast unblocking, easy accumulation of water, etc., to avoid the growth of bacteria and improve work efficiency And, to avoid the effect of odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

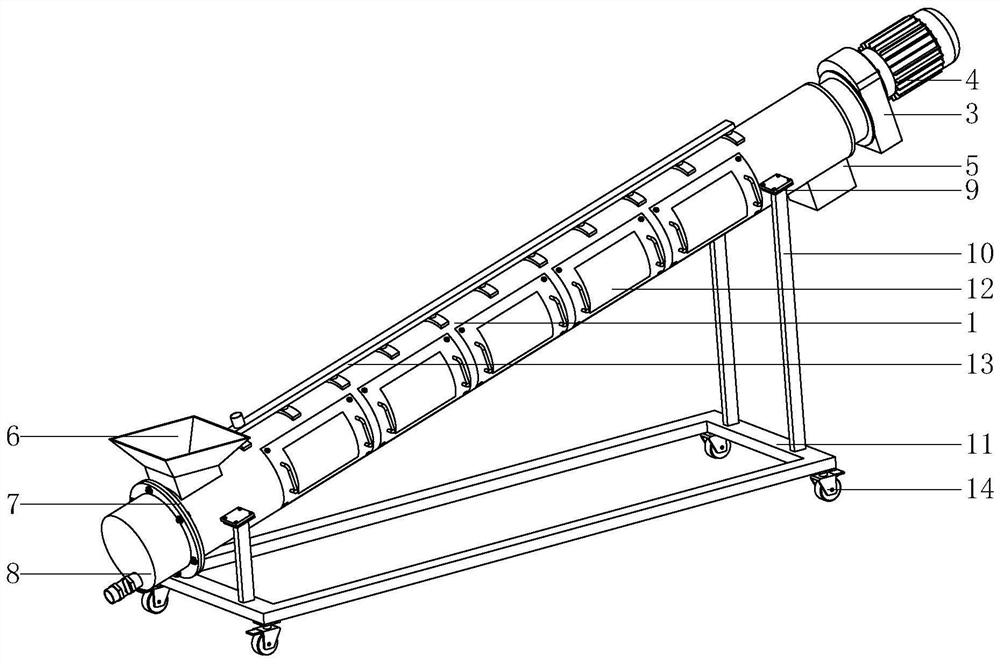

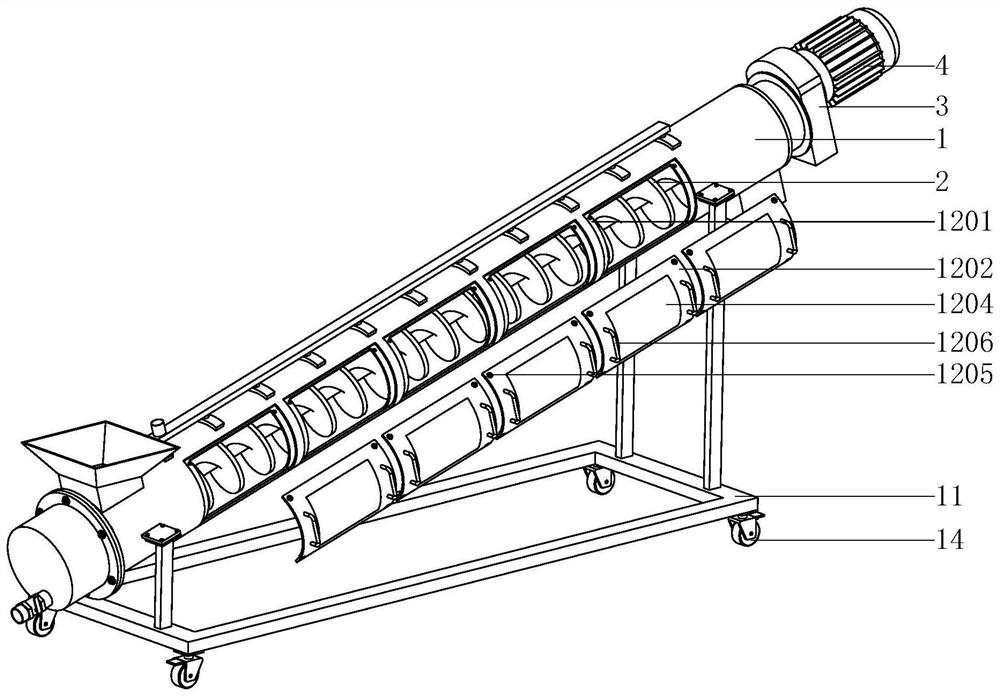

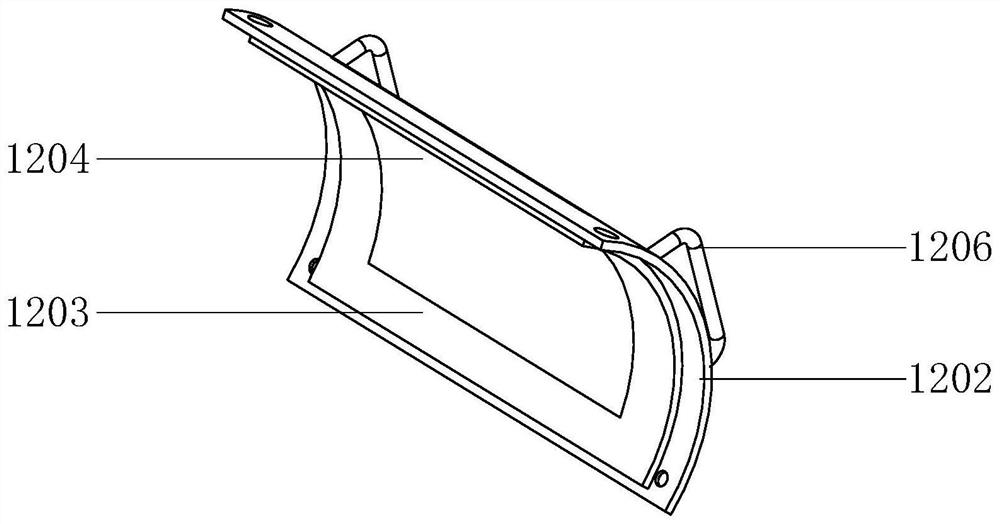

[0031] Such as figure 1 , figure 2 , Figure 5 , Figure 6 and Figure 7 As shown, a tubular screw conveyor for kitchen waste proposed by an embodiment of the present invention includes a conveying shell 1, and a spiral body 2 is rotatably connected inside the conveying shell 1, and the upper shaft end of the spiral body 2 passes through the conveying shell 1 and is connected to There is a reducer 3 and a motor 4 is installed on the reducer 3. The upper and lower side walls of the conveying shell 1 are fixed with a discharge port 5, and the upper and lower side walls of the conveying shell 1 are fixed with a feed inlet 6. A flange 7 is fixed on the peripheral side wall, and one side of the flange 7 is provided with a filtrate structure 8, and a fixed block 9 is fixed on the front and rear side walls of the conveying shell 1, and the fixed block 9 is connected with a support leg 10 through a fixed bolt to support The bottom ends of the legs 10 are jointly connected with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com