Plastic piece mounting device, plastic piece mounting equipment and plastic piece mounting system

An installation device and a technology for plastic parts, which are applied in the field of plastic part installation equipment and plastic part installation systems, can solve the problems that the car roof cannot be installed normally, deviate from the position to be installed, and cannot be engaged, so as to improve work efficiency and save energy. Labor cost, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, the absorbent article related to the present invention will be described in detail with reference to the accompanying drawings.

[0028]

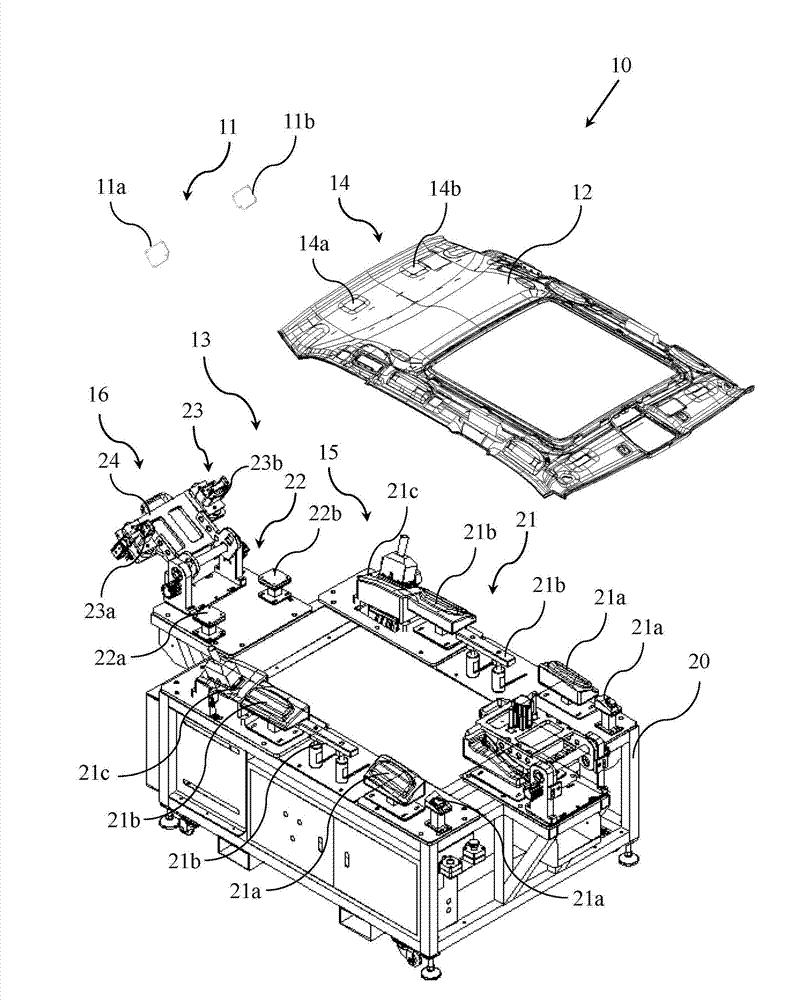

[0029] Fig. 1 is a structural schematic diagram of an embodiment of the plastic part installation system involved in the present invention.

[0030] As shown in FIG. 1 , a plastic part installation system 10 includes a plurality of plastic parts 11 , a car roof 12 and a plastic part installation device 13 .

[0031] In this embodiment, there are two plastic parts 11, and the two plastic parts 11 are buckles 11, which are divided into left buckle 11a and right buckle 11b according to their installation positions.

[0032] On the roof 12 of the car, there are positions 14 to be installed where the left buckle 11a and the right buckle 11b need to be installed, as the left buckle to be installed position 14a and the right buckle to be installed position 14b respectively.

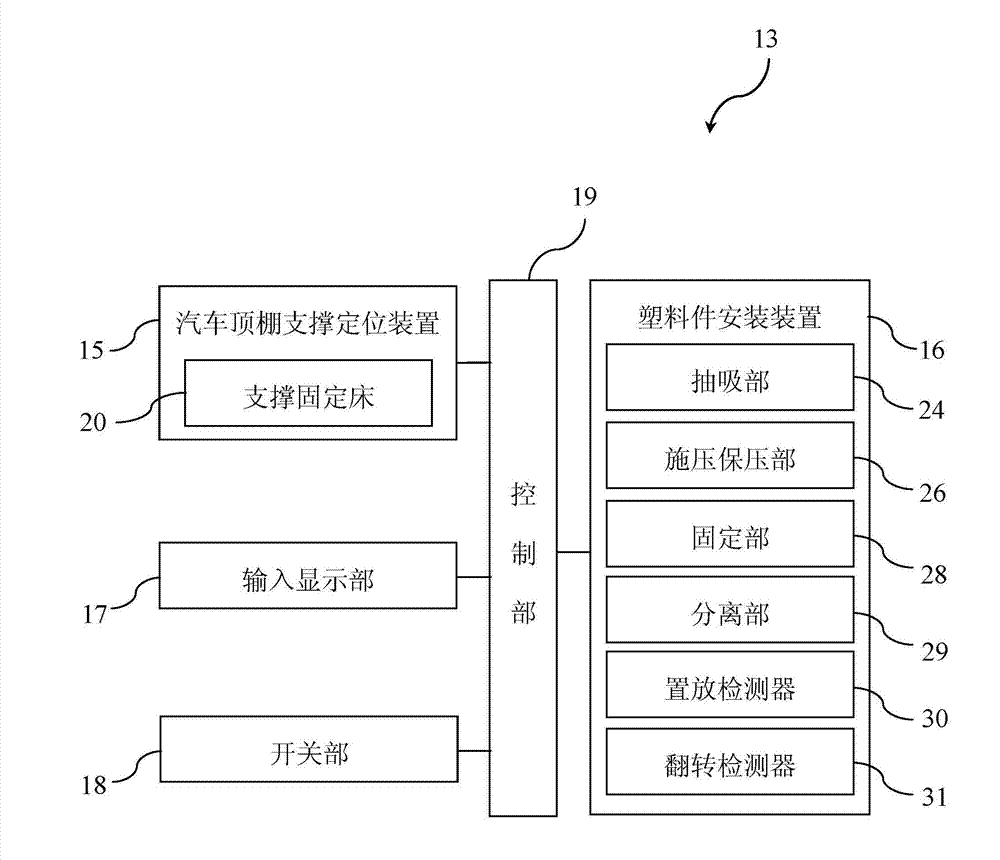

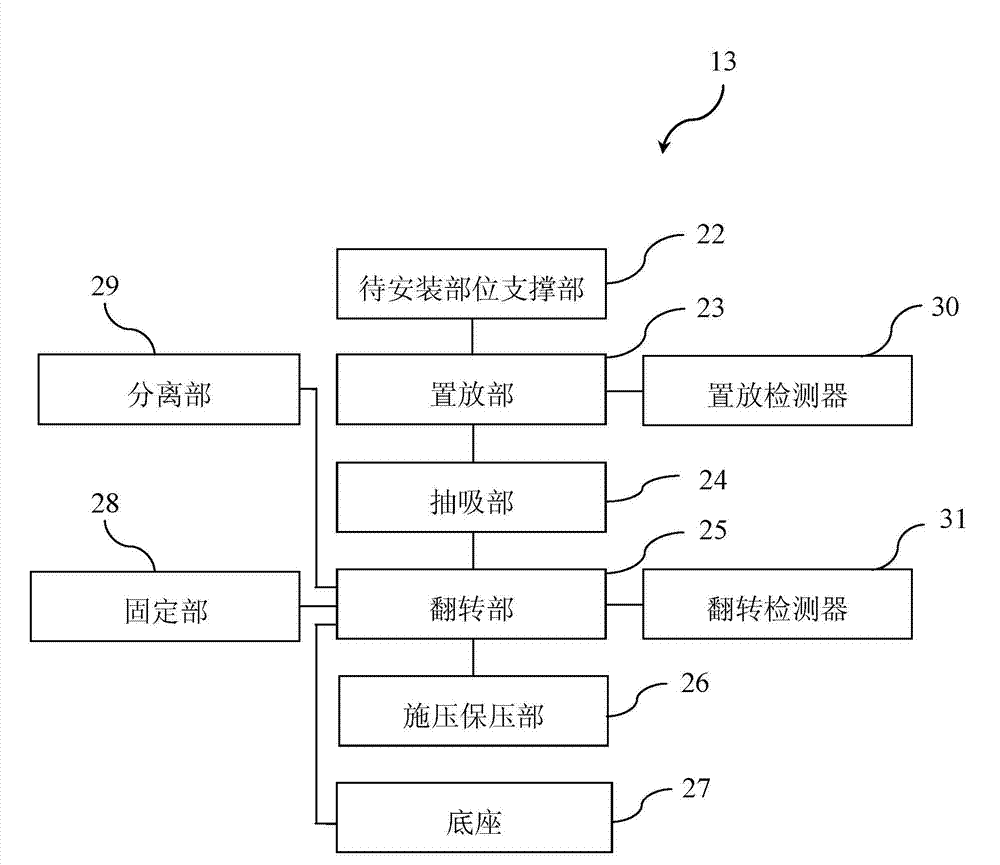

[0033] Fig. 2 is a structural block diagram of an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com