Bearing conveying and lifting device

A technology of bearings and conveying troughs, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of no bearing blank conveying and lifting devices, and achieve the effects of simple structure, convenient use and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Such as Figure 1-4 As shown, a bearing conveying and lifting device includes a conveying trough 9 and a lifting device 10, the discharge port of the conveying trough 9 is located at the lower part of the lifting device 10, and one end of the discharge port of the conveying trough 9 is lower than the other end ;

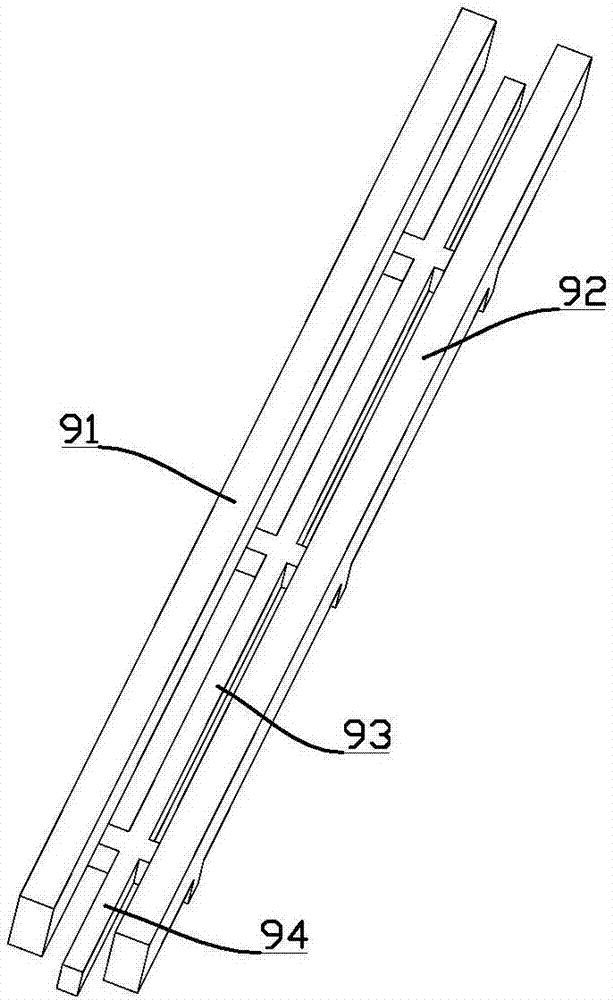

[0021] The conveying trough 9 includes a left baffle plate 91, a right baffle plate 92, and a support rod 93 in the middle between the left baffle plate 91 and the right baffle plate 92, and the left baffle plate 91, the right baffle plate 92 and the support rod 93 are mutually fixed by connecting rod 94;

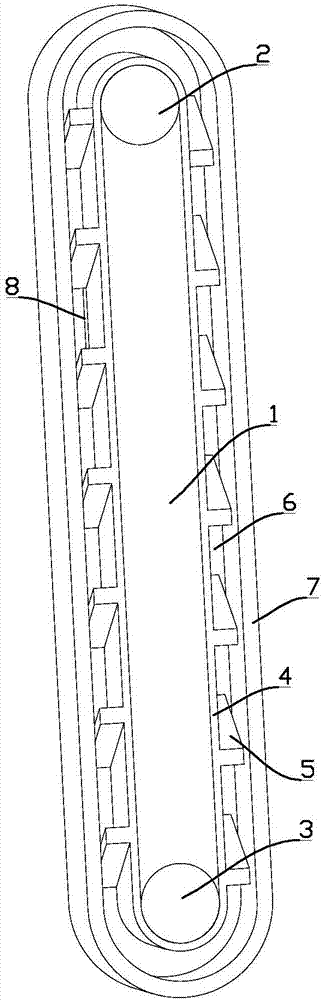

[0022] The lifting device 10 includes a vertically fixed support 1, a driving roller 2 and a driven roller 3 are respectively fixed on the top and bottom of the support 1, and a conveyor belt 4 is covered on the outside of the support 1. The conveyor belt 4 is driven by the driving roller 2, and the outer surface of the conveyor belt 4 is evenly fixed wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com