Bearing feeding and conveying device capable of adjusting

A conveying device and bearing technology, which is applied in the field of bearing feeding and conveying devices, can solve the problem of no bearing embryo body feeding and conveying device, and achieve the effect of being conducive to conveying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

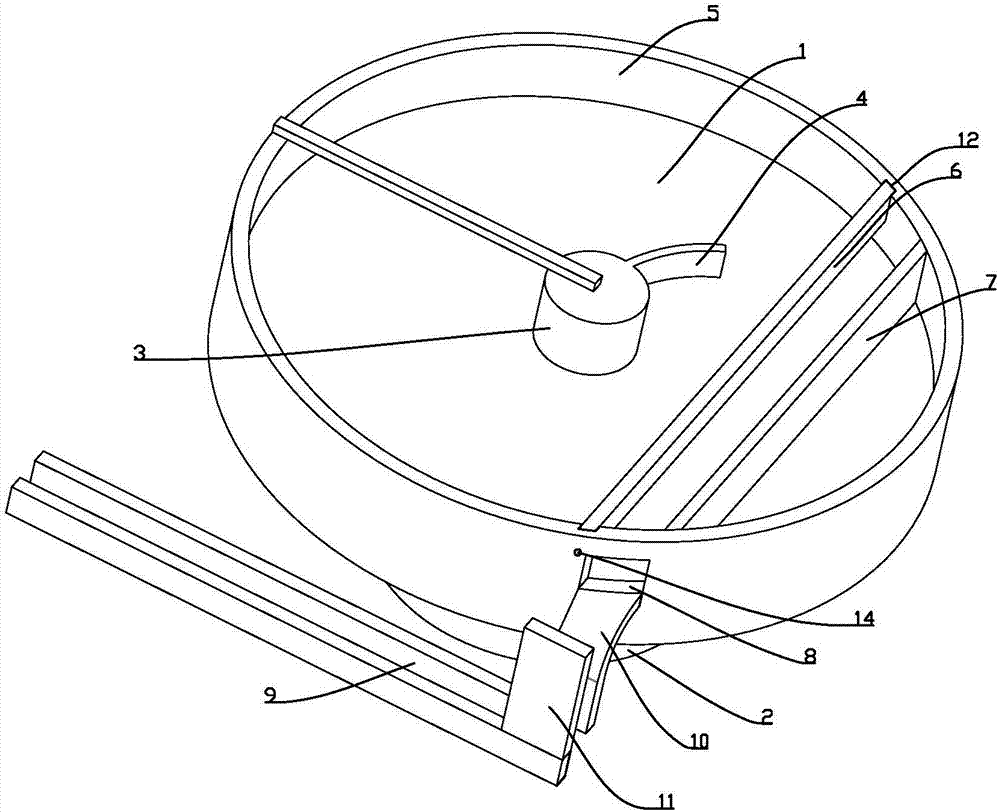

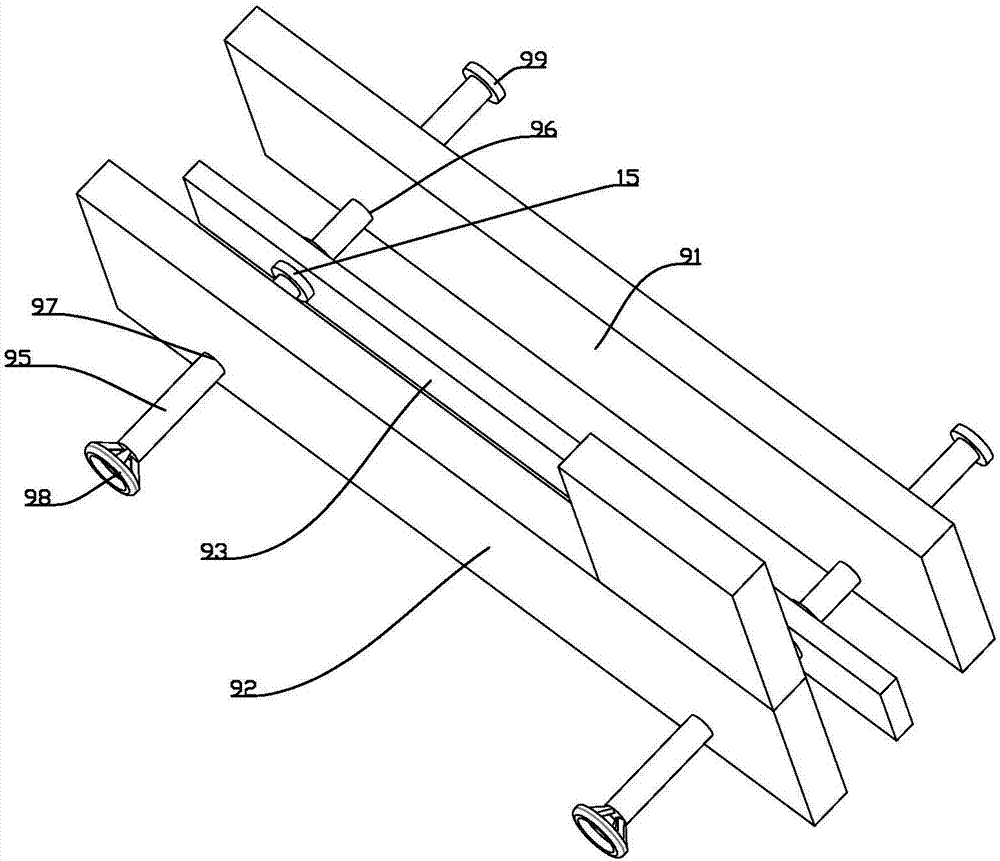

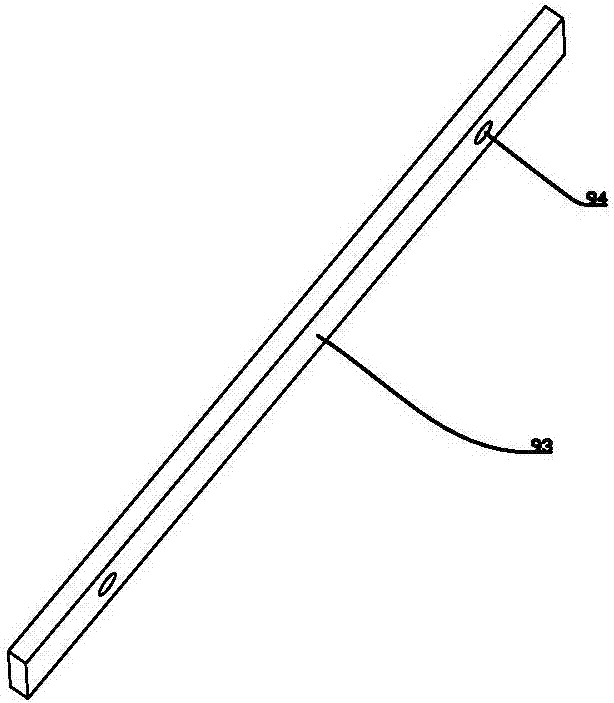

[0023] Such as Figure 1-4 As shown, an adjustable bearing feeding and conveying device includes a turntable 1, and a motor 2 that drives the turntable 1 to rotate at the bottom of the turntable 1. A rotating block 3 coaxial with the turntable 1 is arranged at the center of the top of the turntable 1. The rotating block 3 is relatively rotated with the turntable 1, and a horizontal cleaning rod 4 is fixed on the side of the rotating block 3. There is a gap between the cleaning rod 4 and the top of the turntable 1, and the side of the turntable 1 There is a retaining ring 5 which is separated from the turntable 1, and the retaining ring 5 is provided with a first baffle plate 6 and a second baffle plate 7 parallel to each other above the turntable 1, and the first baffle plate 6 is close to the In the center of the turntable 1, the baffle ring 5 is provided with a pair of baffle grooves 12 at the position where it meets the first baffle 6, and the baffle grooves 12 are slidably...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com