Quantitative feeding system for anode casting machine

A quantitative feeding and casting machine technology, applied to casting equipment, equipment for supplying molten metal, metal processing equipment, etc., can solve the problems of waste, many pollutants, and difficult control of raw material delivery, so as to reduce pollution and improve use rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

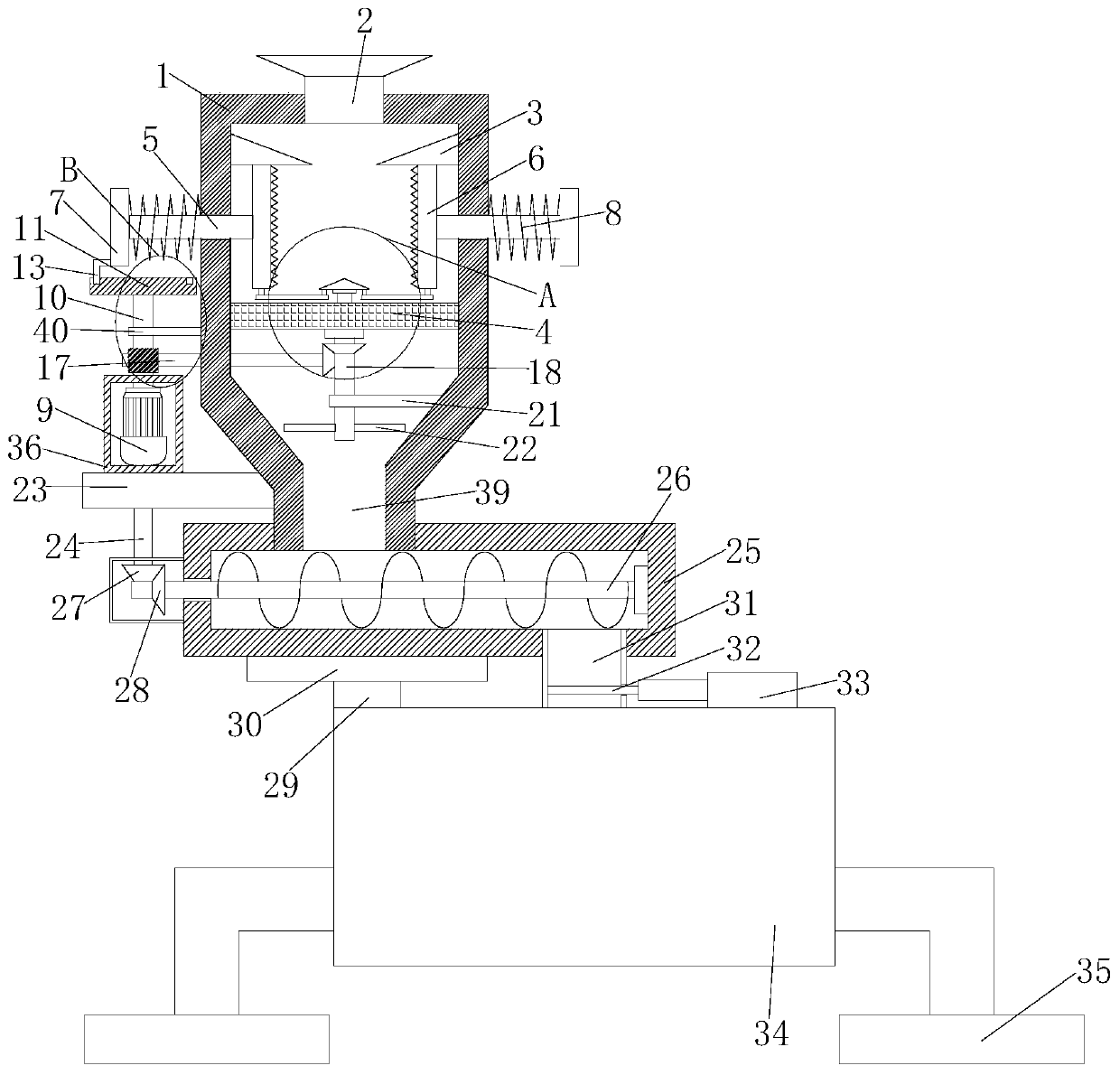

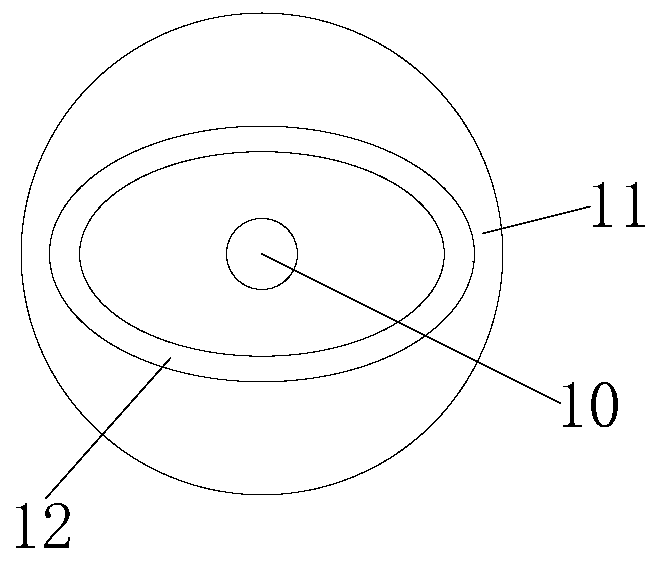

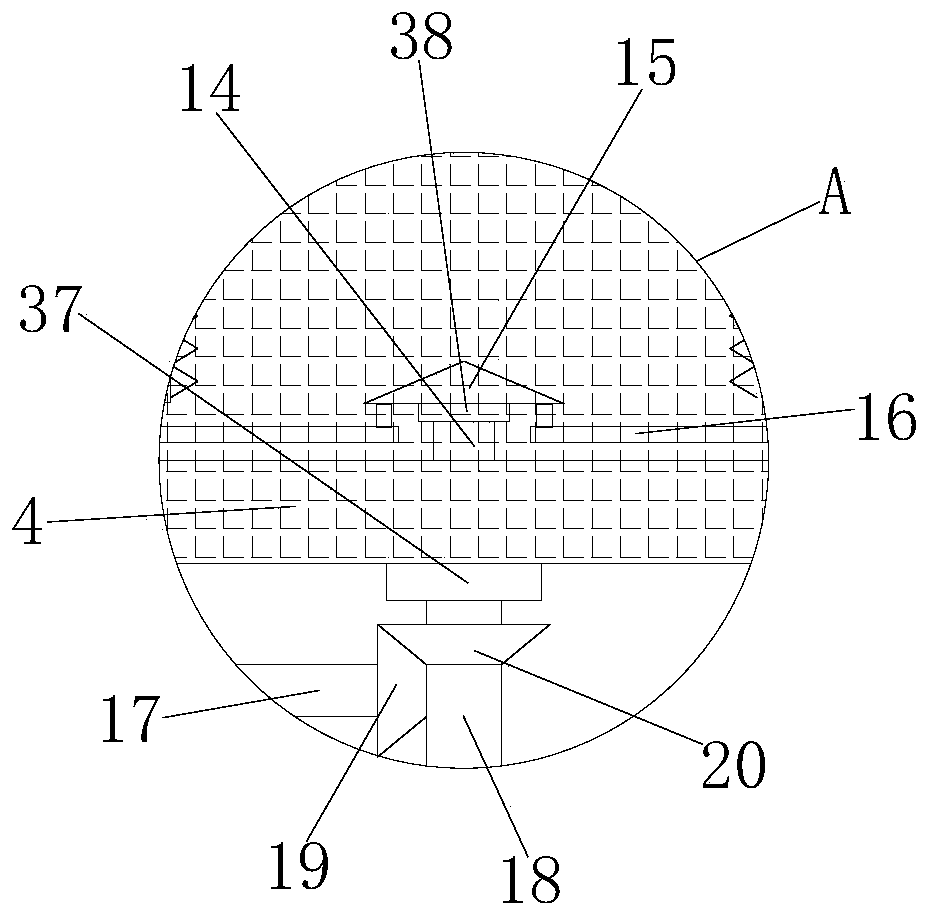

Embodiment 1

[0028] refer to Figure 1-5 , a quantitative feeding system for an anode casting machine, comprising a treatment box 1 and a casting machine 34, the top of the treatment box 1 is provided with a material inlet 2, the bottom of the treatment box 1 is provided with a discharge port 39, and the two sides of the treatment box 1 Two slant plates 3 are installed symmetrically and fixedly on the inner wall, which is convenient for material guiding. A filter plate 4 is fixed inside the treatment box 1. Support rods 5 are slidingly installed on both sides of the treatment box 1, and one side of the two support rods 5 is fixed. A crushing plate 6 is installed, and the two crushing plates 6 are matched, and the other side of the two support rods 5 is fixedly equipped with a fixed plate 7, and one side of the processing box 1 is fixedly installed with a mounting plate 23, and the top of the mounting plate 23 An installation box 36 is fixedly installed, and a double-axis motor 9 is fixedly...

Embodiment 2

[0039] refer to Figure 1-5 , a quantitative feeding system for an anode casting machine, comprising a treatment box 1 and a casting machine 34, the top of the treatment box 1 is provided with a material inlet 2, the bottom of the treatment box 1 is provided with a discharge port 39, and the two sides of the treatment box 1 Two slant plates 3 are installed symmetrically on the inner wall by welding to facilitate material guidance. A filter plate 4 is fixed inside the processing box 1, and support rods 5 are slidingly installed on both sides of the processing box 1. One side of the two support rods 5 Both are fixedly installed with a crushing plate 6 by welding, and the two crushing plates 6 are matched, and the other side of the two support rods 5 is fixedly installed with a fixed plate 7 by welding, and one side of the processing box 1 is fixedly installed with a mounting plate 7 by welding. plate 23, the top of the mounting plate 23 is fixedly installed with an installation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com