Full-automatic coal bunker water cannon dredging device

A fully automatic, coal bunker technology, applied in the field of coal bunker equipment, can solve problems such as limited dredging effect of fixed rapping, increased coal flow resistance, uneven flow, etc., to avoid unsafe factors in unit operation and reduce fuel oil self-injection , The effect of eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

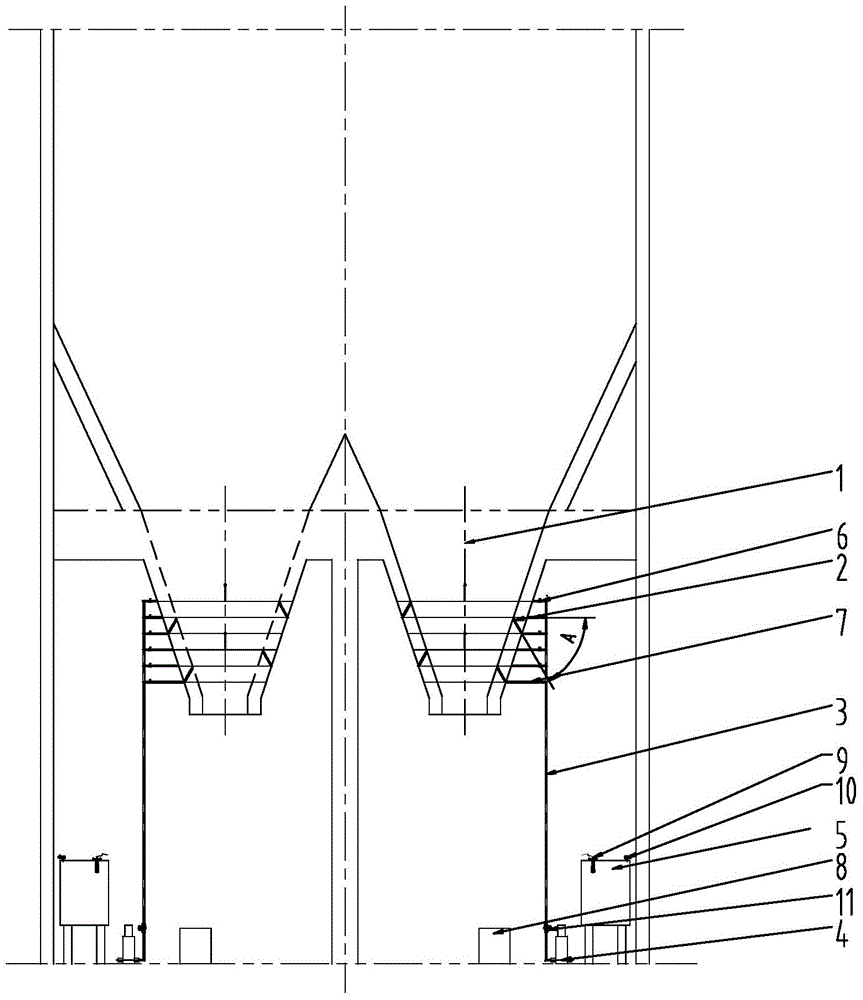

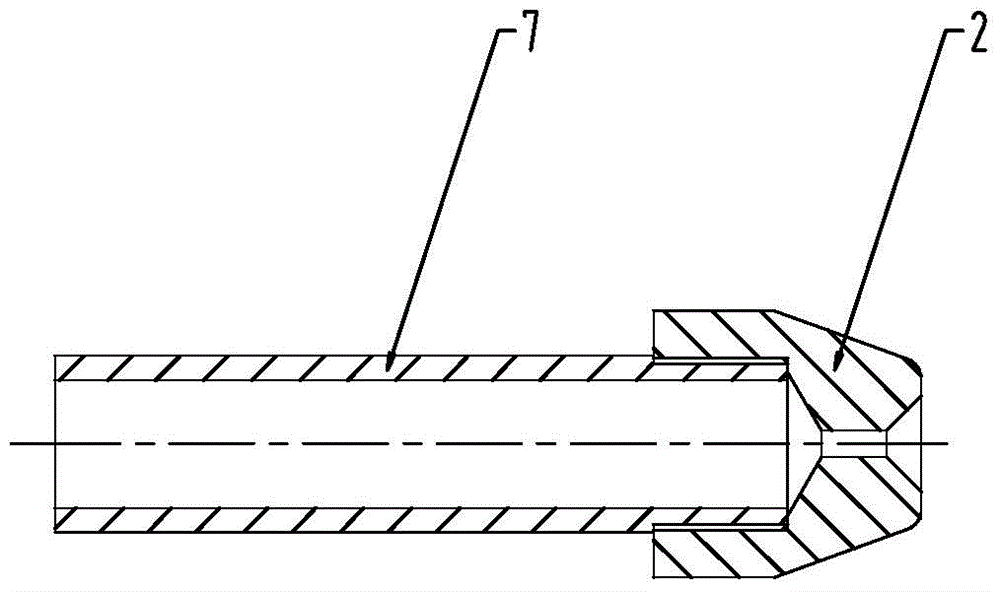

[0017] Such as Figure 1~2 As shown, the present invention mainly includes a plurality of nozzles 2, a water delivery pipeline 3 and a water tank 5. The plurality of nozzles 2 are evenly distributed on the surface of the feed port 1 of the coal bunker in a spiral shape, and each nozzle 2 is jointly connected with the water delivery pipe 7 The main pipe 3 and the water main pipe 3 are connected to the water tank 5, and the water in the water tank 5 is sent to each nozzle 2 through the water main pipe 3 and the water delivery pipe 7, and then sprayed to the inner surface of the coal bunker feeding port 1 through the nozzle 2, to prevent the blockage The coal material is flushed and blocked.

[0018] The water main pipe 3 is provided with a one-way valve 11 . The water delivery pipe 7 is provided with a solenoid valve 6, and the solenoid valve 6 control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com