High-speed rail crts Ⅱ type slab ballastless track track slab gap adjustment method

A slab ballastless track and track slab technology, which is applied in tracks, track laying, track maintenance, etc., can solve the problems of long construction period, impact on driving time, and high implementation cost, and achieve convenient construction, restrain lateral movement, and reduce The effect of remediation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In this embodiment, the high-speed railway CRTSⅡ type slab ballastless track track slab gap adjustment method is carried out according to the following steps:

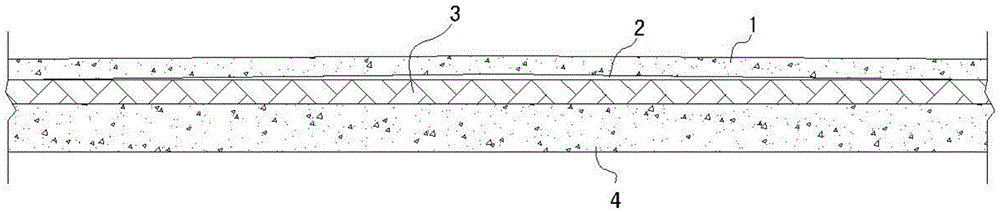

[0032] Step 1: If figure 1 As shown, the separation condition of the track slab 1 is measured, and the processing conditions are determined as follows: the track slab 1 appears as a separation track slab due to the unilateral separation or the horizontal through separation, and the separation track slab is formed due to the occurrence of the separation 2 The amount of arching is not more than 2mm.

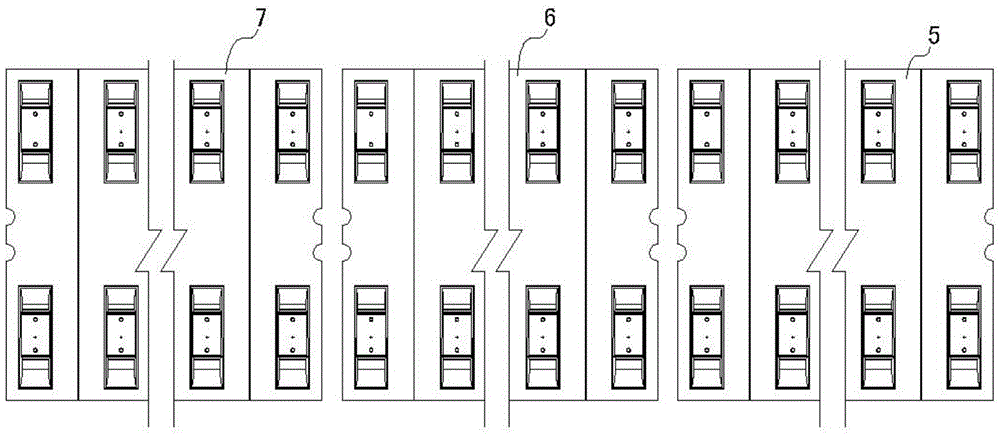

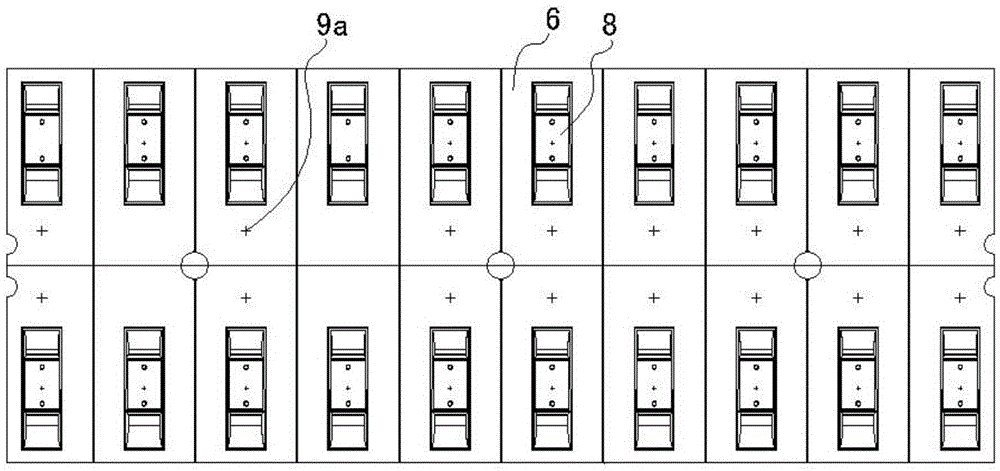

[0033] Step 2: If figure 2 As shown, with the separated track slab 5 as the central track slab, two track slabs are set on both symmetrical sides of the central track slab as anchoring track slabs. For the anchoring track slabs, anchoring ribs are used to anchor the anchoring track slabs. Fixing; the distribution form of the anchoring ribs in the anchoring track slab is: from the center track slab towards the dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com