Automatic cutting device for plastic bottle opening residues

An automatic cutting device and plastic bottle technology, which is applied to household components, other household appliances, household appliances, etc., can solve the problem of manual cutting of the remaining materials in the clamping part, improve cutting efficiency, avoid easy tilting, and ensure flatness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

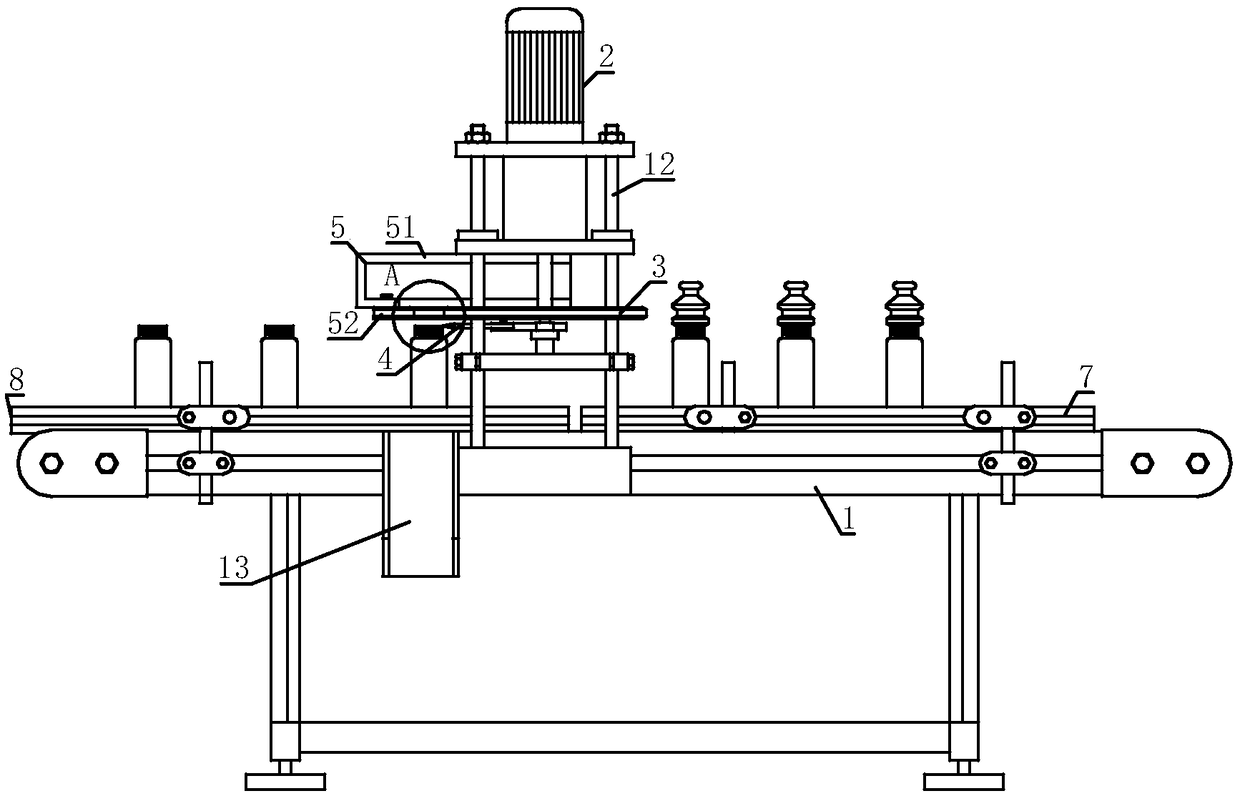

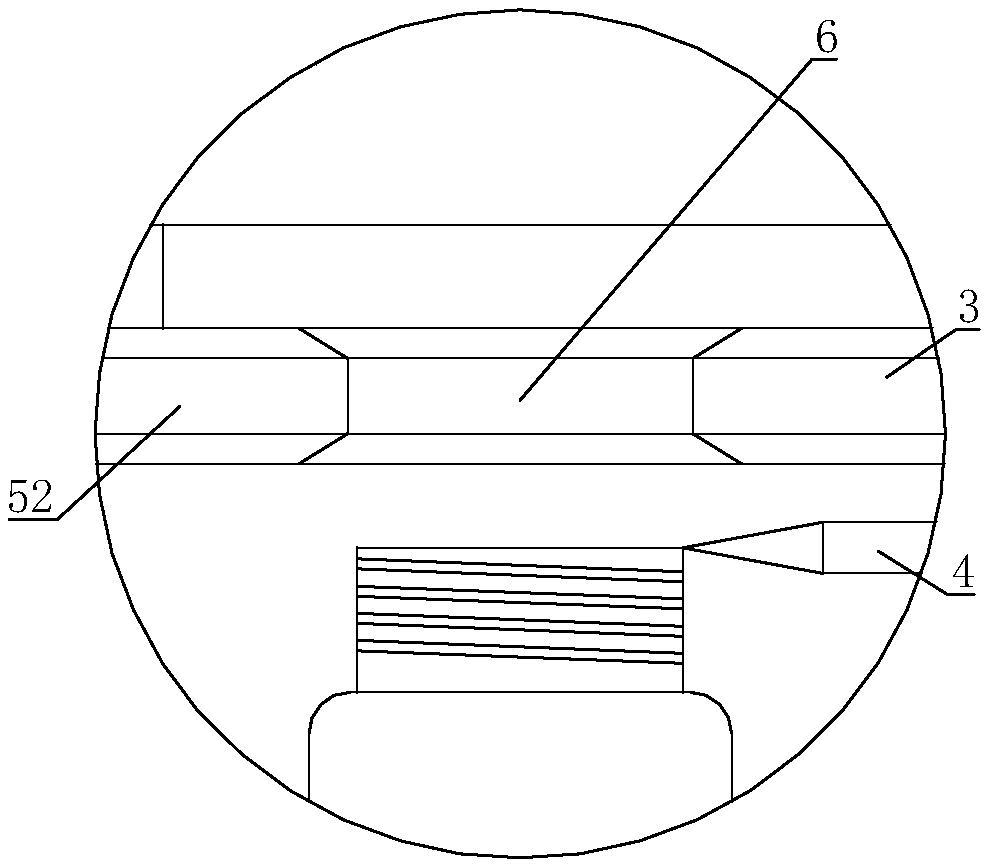

[0033] An automatic cutting device for plastic bottle mouth remaining material, comprising a frame 1, a conveyor belt 11 and a bracket 12 are installed on the frame 1, a driving mechanism 2 is installed on the bracket 12, and a rotating disk 3 is connected to the output shaft of the driving mechanism 2 , a cutting knife 4 is fixed on the bracket 12, and the cutting knife 4 is located below the rotating disk 3; The area of the plastic bottle forms a rotating clamping groove 6 for clamping and rotating the plastic bottle.

[0034] The conveyor belt 11 of the present invention can transport the plastic bottle with the remaining material of the clamping part of the bottle mouth into the rotating clamping groove 6, so that the remaining material of the clamping part of the bottle mouth of the plastic bottle can be cut off here. The driving mechanism 2 drives the rotating disk 3 to rotate, and the clamping part of the bottle mouth of the plastic bottle can continuously rotate unde...

Embodiment 2

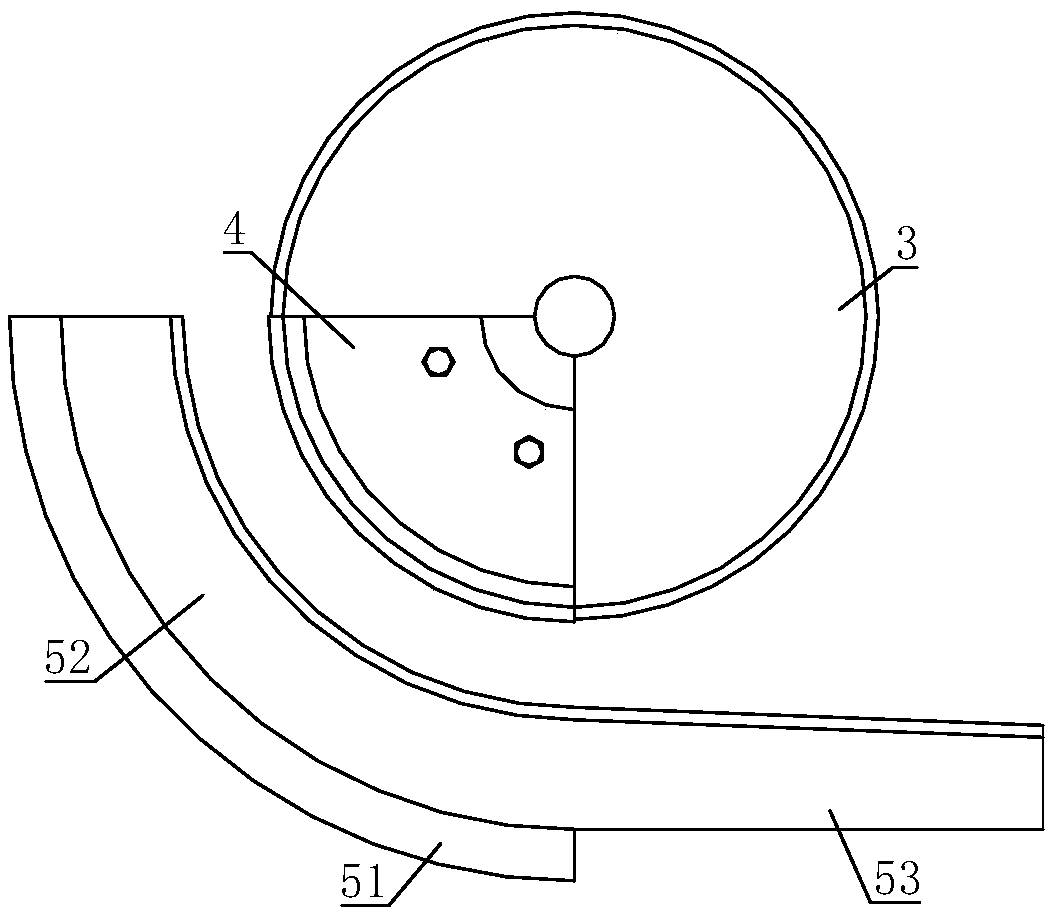

[0036] On the basis of Embodiment 1, the clamping mechanism 5 includes a fixing groove 51, the fixing groove 51 is installed on the bracket 12, and the lower end of the fixing groove 51 is fixedly connected with an arc clamping plate 52, and the arc clamping plate 52 is connected with the The rotating disk 3 is concentric, the height of the circular arc clamping plate 52 is the same as that of the rotating disk 3 , and the rotating clamping groove 6 is an arc-shaped area between the circular arc clamping plate 52 and the rotating disk 3 .

[0037] The arc clamping plate 52 is concentric with the rotating disc 3 and has the same height, so the plastic bottle can be stably clamped by the arc clamping plate 52 and the rotating disc 3, avoiding the shaking or tilting of the plastic bottle during cutting, ensuring The incision of the bottle mouth is smooth.

Embodiment 3

[0039] On the basis of Embodiment 1 or Embodiment 2, a guide plate 53 is fixed on the side of the circular arc clamping plate 52 close to the entrance of the conveyor belt 11 .

[0040] The guide plate 53 can lead the plastic bottle into the rotating clamping groove 6, so that the plastic bottle can enter the rotating clamping groove 6 stably and slowly, avoiding the situation that the plastic bottle is easy to tilt when the plastic bottle directly enters the rotating clamping groove 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com