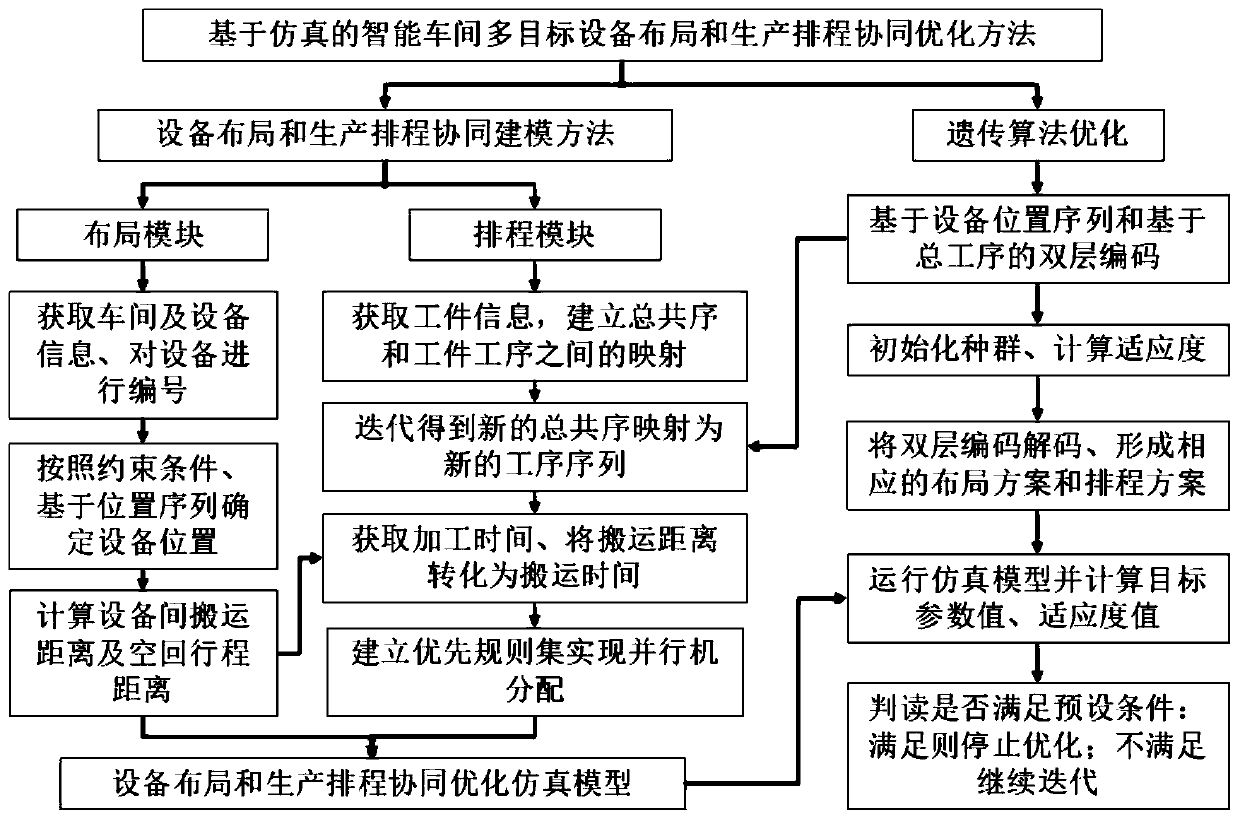

Multi-target equipment layout and production scheduling collaborative optimization method based on simulation

A technology for production scheduling and collaborative optimization, applied in genetic models, genetic laws, resources, etc., can solve the problems of ignoring machine flexibility, inability to collaboratively optimize, and reducing practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

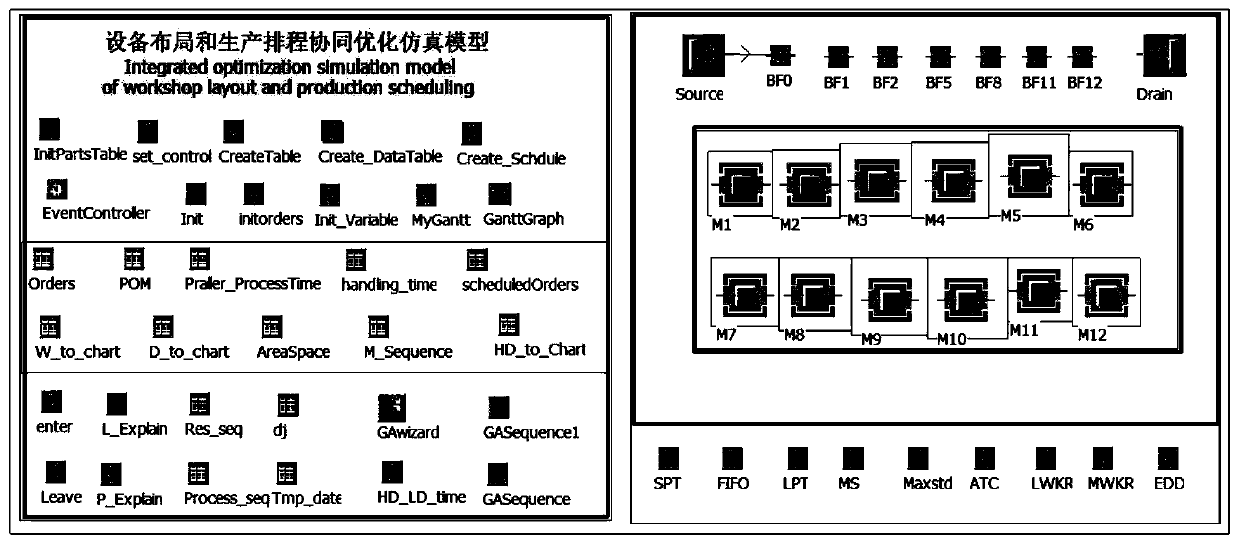

Examples

Embodiment

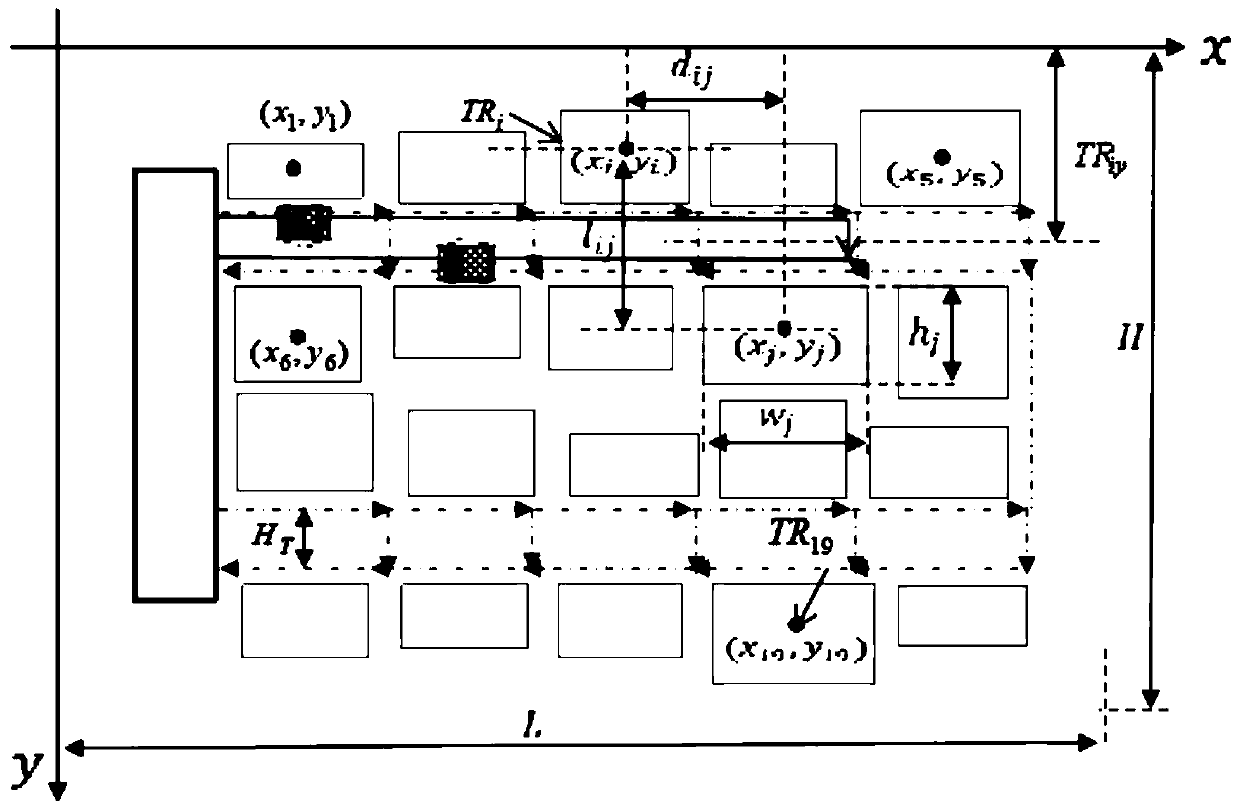

[0125] S101. Build a device layout

[0126]S1011. Optimize the layout and production schedule of the equipment of a certain mold production line. The production area that can be used for planning is 11×18m, and there are 12 processing equipment in total. The matrix form of the sequence formed by the initial equipment number is:

[0127] X=[1,2,3,4,5,6,7,8,9,10,11,12]

[0128] The corresponding processing equipment is [milling machine, CNC1, CNC2, CNC3, wire cutting 1, wire cutting 2, wire cutting 3, EDM 1, EDM 2, EDM 3, grinding machine, coordinate measuring instrument], and the corresponding equipment size The formed matrix is:

[0129]

[0130] S1012, according to the above steps to place each device to get the position

[0131] S1013. The matrix of the transport distance and empty return travel distance determined based on the equipment position and the AGV track is a 12×12 matrix, and the corresponding matrix is:

[0132]

[0133]

[0134] S102. Generate a sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com