Inclination-resistant oil sump for engine

An oil pan and engine technology, applied in the direction of pressure lubrication of lubricating pumps, etc., can solve problems such as difficulty in solving engine reliability problems, and achieve the effects of improving oil supply reliability, simplifying layout, and reducing height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

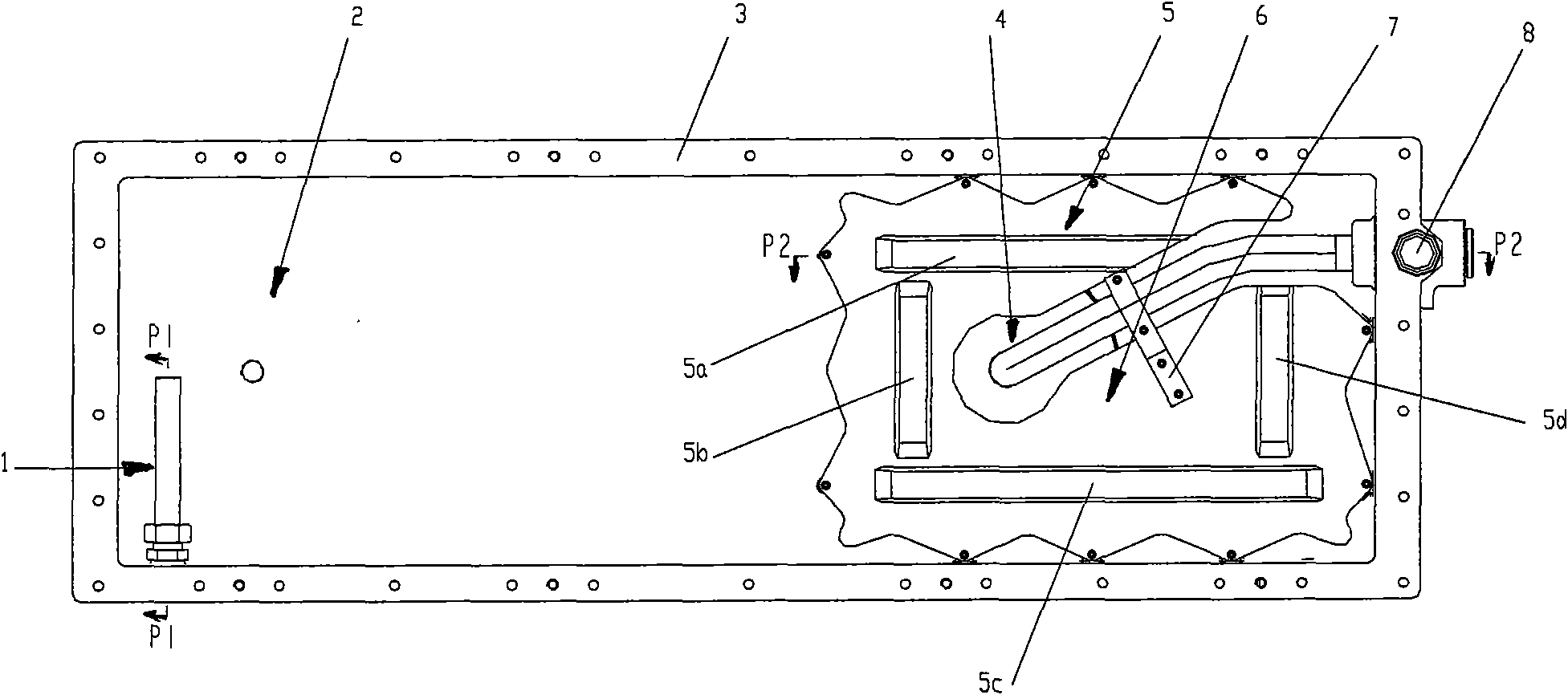

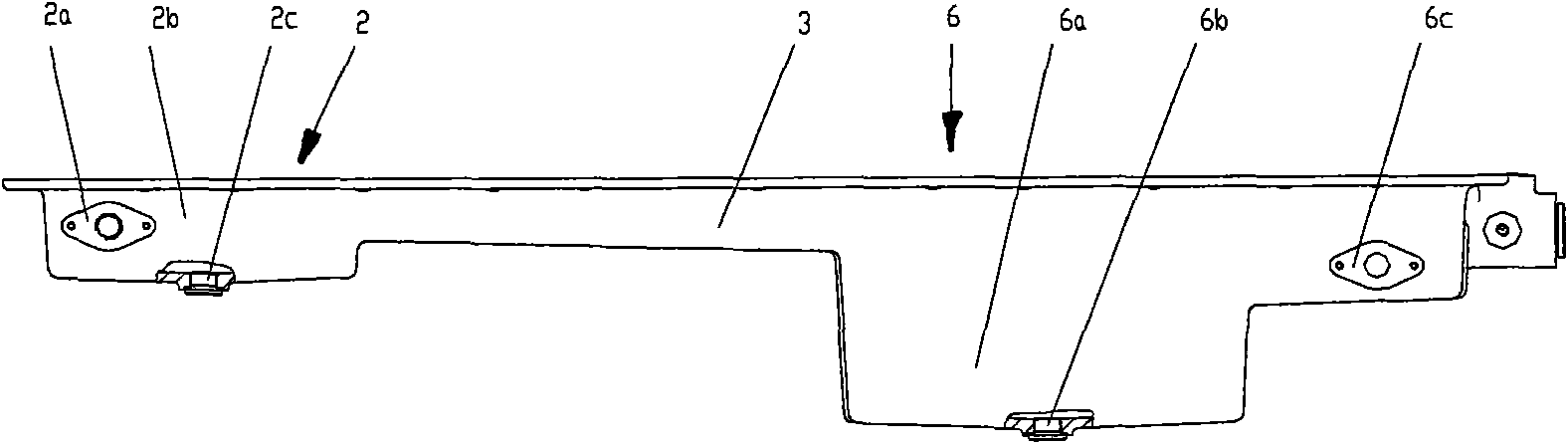

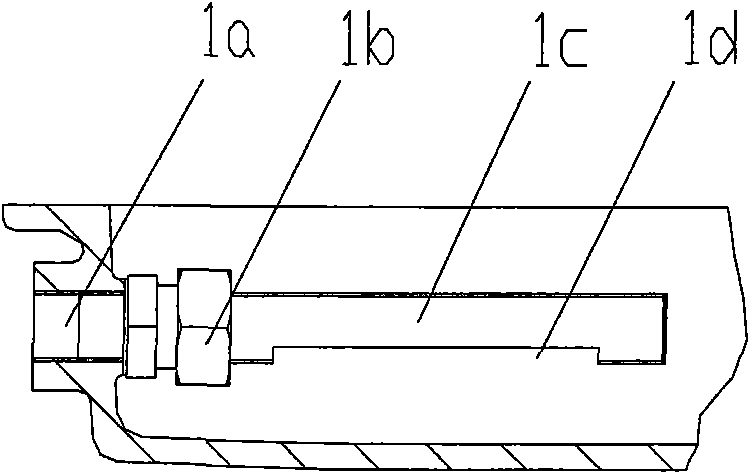

[0029] Figure 1 to Figure 4 Shown is a specific embodiment of the anti-tilt oil pan for the engine of the present invention. The oil pan is arranged at the bottom of the engine and can be upside down. It is suitable for internal combustion engines and Stirling engines, and is especially suitable for harsh working conditions. Especially in the application fields of engines under large tilt and swing conditions, such as mountain vehicle engines and marine engines. The present invention includes an oil sump body 3, an oil suction pipe assembly 1, an oil suction pipe assembly 4, and two oil storage chambers, a shallow oil chamber 2b and a deep oil chamber 6a formed by partially recessing the oil sump body 3. The sump body 3 has a long structure along the axial direction of the engine. Two oil storage chambers are respectively arranged near both ends of the oil sump with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com