Floating type sliding block core pulling and demoulding mechanism

A slider core-pulling and demoulding mechanism technology, which is applied to other household appliances, household appliances, applications, etc., can solve the problems of increasing mold height and manufacturing difficulty, affecting product appearance quality, ejection marks, etc., to ensure product quality The effect of improving molding quality, reducing mold production cost, and reducing product injection cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

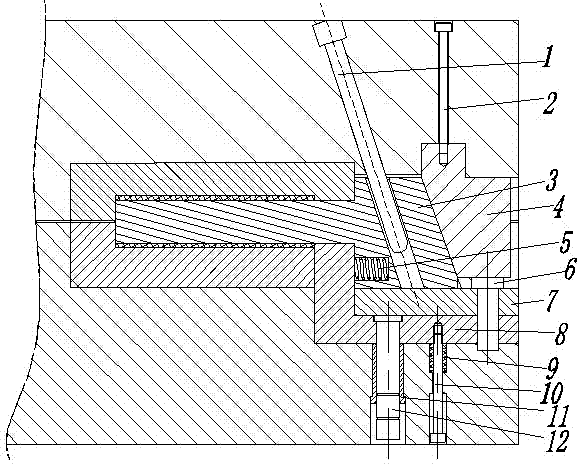

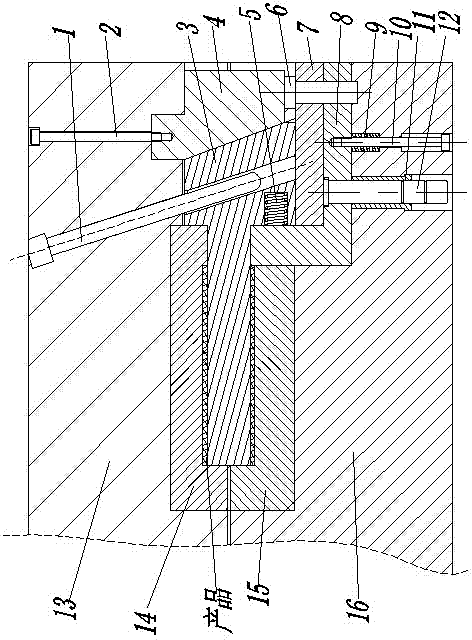

[0013] Figure 1-3 Shown is the relevant explanatory drawing of the present invention;

[0014] A floating slider core-pulling and demoulding mechanism, including an inclined guide column 1, a compression block screw 2, a long core slider body 3, a compression block 4, a slider body spring 5, and a slider body limit pin 6 , slider body chute plate 7, material retaining floating plate 8, floating plate spring 9, floating plate pull rod 10, guide sleeve 11, floating plate guide post 12, such as figure 2 shown.

[0015] The inclined guide post 1 is installed on the mold template, and the pressing block 4 is installed on the mold template through the pressing block screw 2;

[0016] The long core slider body 3 is installed on the slider body chute plate 7, and can move left and right along the inner chute of the slider body chute plate 7; the slider body limit pin 6 is installed on the slider body chute plate 7, the slider body spring 5 is compressed and installed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com