Continuous countercurrent supercritical fluid extraction equipment and method applied to materials

A supercritical fluid and extraction technology, applied in chemical instruments and methods, solvent extraction, separation methods, etc., can solve the problems of high equipment cost of extraction tower, inconvenient operation and maintenance, limit of theoretical plate number, etc., to increase theoretical plate The effect of reducing the design height and avoiding errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

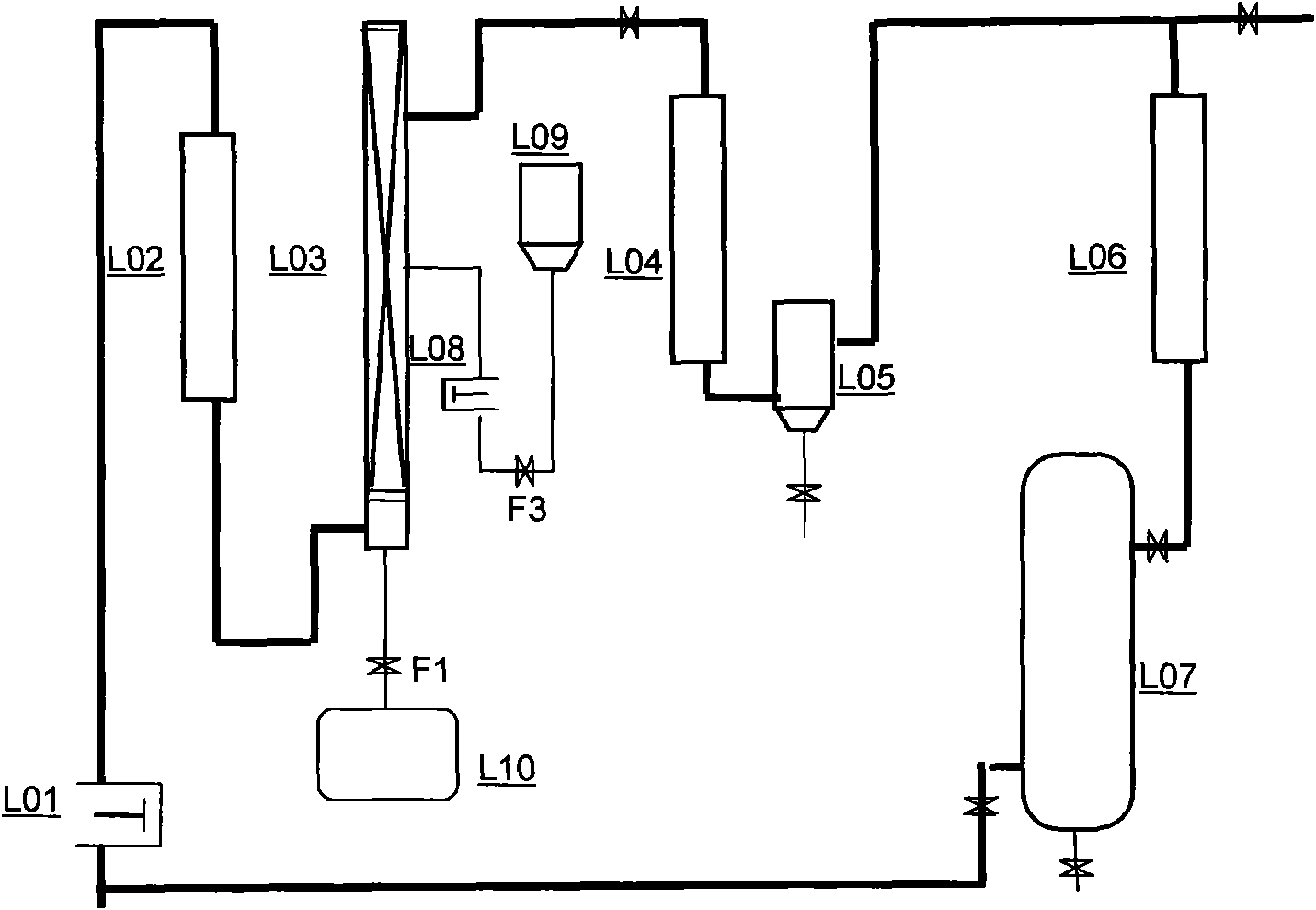

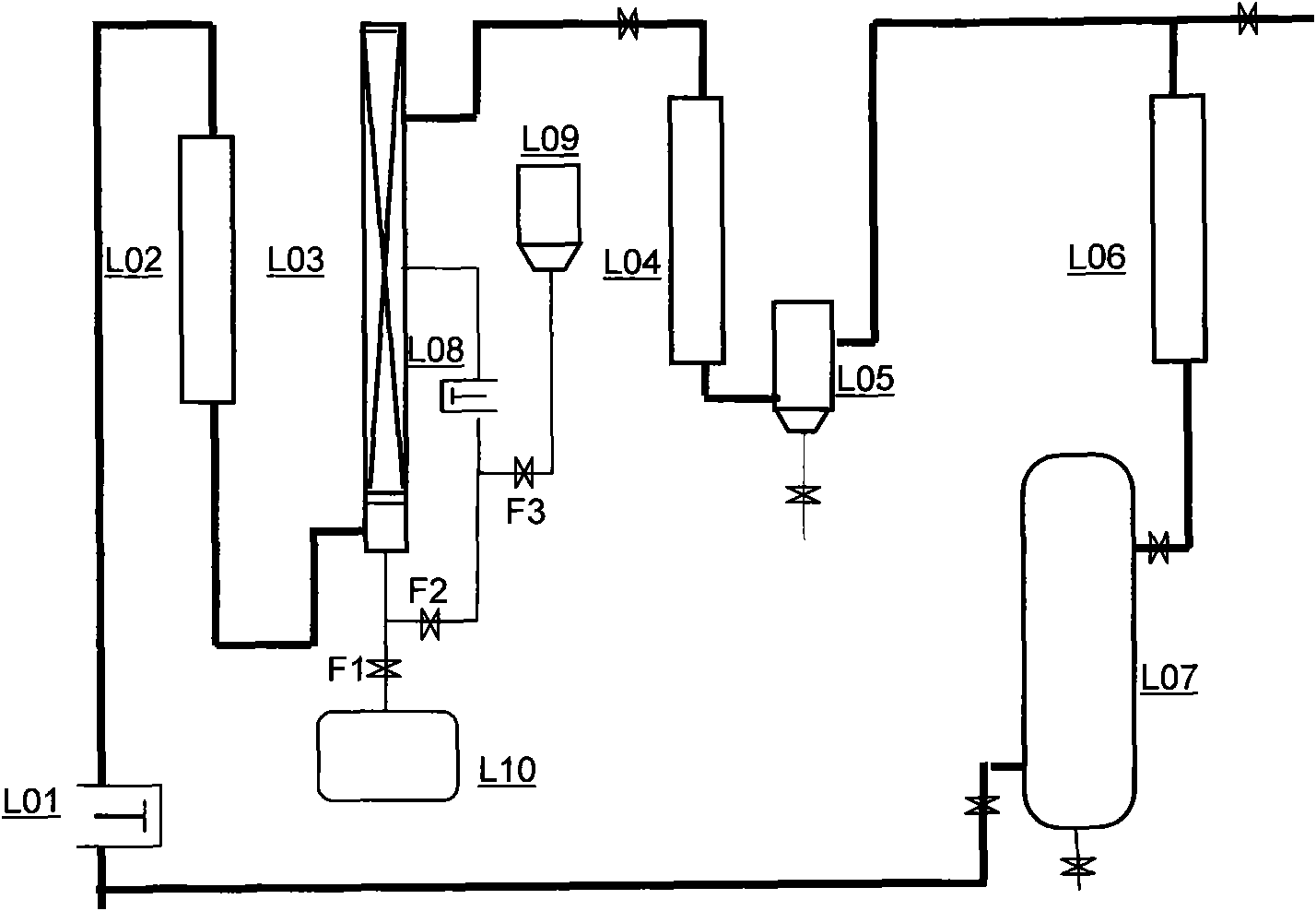

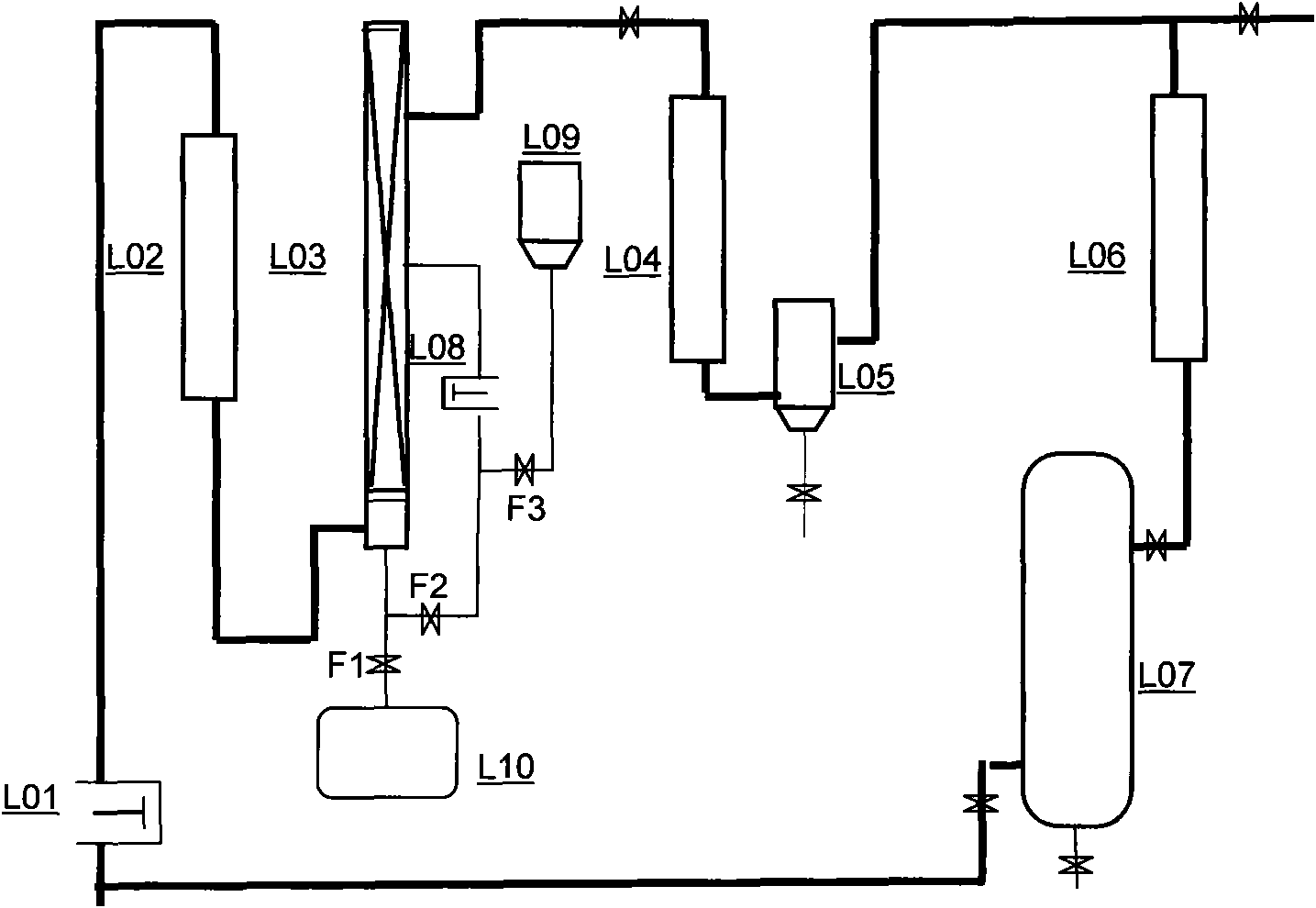

[0014] A kind of equipment and method (see attached figure 2 ), is that there is a booster pump L01, the lower part is connected with the preheater L02 and the countercurrent extraction tower L03 through the pipeline in turn, and the upper outlet of the countercurrent extraction tower L03 is connected with the heat exchanger L04 and the separation unit L05 through the pipeline, with The feed pipeline of the raw material pump L08 communicates with the upper part of the countercurrent extraction tower L03. The discharge pipeline at the bottom of the countercurrent extraction tower is divided into two circuits, one is equipped with a discharge valve F1, and the other is equipped with a raw material circulation valve F2, which is connected to the feed pipeline at the suction end of the raw material pump L08 through the pipeline. The feed pipe at the suction end of the raw material pump L08 is connected in parallel with the outlet pipeline of the raw material tank and the valve F3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com