Preparation method of special capillary chromatographic column for detecting Baijiu

A capillary chromatographic column and capillary column technology, which is applied in the field of preparation of special capillary chromatographic columns for liquor detection, can solve the problems of affecting the service life of PEG-20M capillary columns, affecting accurate quantification, tailing of acid substances, etc., and achieve long service life , improve quantitative accuracy, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

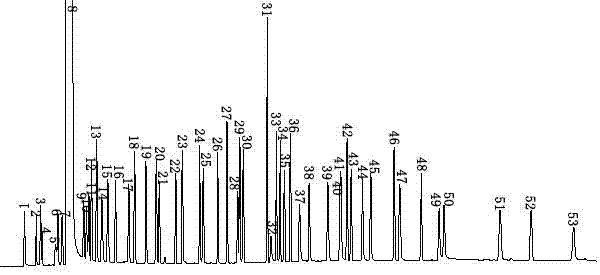

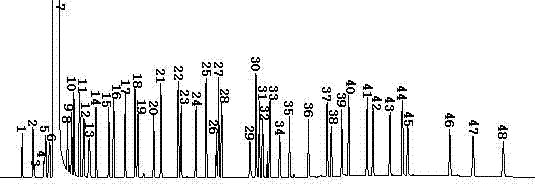

Image

Examples

Embodiment 1

[0023] Example 1 The preparation method of a special capillary chromatographic column for liquor detection comprises the following steps:

[0024] (1) First rinse the inner wall of the elastic quartz capillary column with 1 mol / L HCl, then rinse the inner wall of the elastic quartz capillary column with water for 3 times, and finally install the rinsed elastic quartz capillary column on the chromatographic instrument, and purge it with nitrogen. Heat to 250°C and keep for 5h to obtain a pretreated elastic quartz capillary column.

[0025] Among them: the column length of the elastic quartz capillary column is 50m, the inner diameter is 0.32mm, and the film thickness is 1.0um.

[0026] (2) Accurately weigh 50 mg of bentonite, add 50 mL of toluene, and conduct ultrasonic treatment at a frequency of 35KHz. After 30 minutes, the suspension of bentonite is obtained.

[0027] (3) Use the dynamic method to sequentially coat the organic bentonite suspension from both ends of the pret...

Embodiment 2

[0033] Example 2 The preparation method of a special capillary chromatographic column for liquor detection, comprising the following steps:

[0034] (1) First rinse the inner wall of the elastic quartz capillary column with 3 mol / L HCl, then rinse the inner wall of the elastic quartz capillary column with water for 3 times, and finally install the rinsed elastic quartz capillary column on the chromatographic instrument, and purge it with nitrogen. Heated to 200°C and kept for 6 hours to obtain a pretreated elastic quartz capillary column.

[0035] Among them: the column length of the elastic quartz capillary column is 50m, the inner diameter is 0.32mm, and the film thickness is 0.5um.

[0036] (2) Accurately weigh 50 mg of bentonite, add 50 mL of toluene, and perform ultrasonic treatment at a frequency of 45KHz. After 30 minutes, the suspension of bentonite is obtained.

[0037] (3) Use the dynamic method to successively coat the organic bentonite suspension from both ends of...

Embodiment 3

[0043] Example 3 The preparation method of a special capillary chromatographic column for liquor detection, comprising the following steps:

[0044] (1) First rinse the inner wall of the elastic quartz capillary column with 2 mol / L HCl, then rinse the inner wall of the elastic quartz capillary column with water for 4 times, and finally install the rinsed elastic quartz capillary column on the chromatographic instrument, and purge it with nitrogen. Heated to 300°C and kept for 4 hours to obtain a pretreated elastic quartz capillary column.

[0045] Wherein: the column length of the elastic quartz capillary column is 100m, the inner diameter is 0.25mm, and the film thickness is 0.5um.

[0046] (2) Accurately weigh 50 mg of bentonite, add 50 mL of toluene, and conduct ultrasonic treatment at a frequency of 40KHz. After 30 minutes, the suspension of bentonite is obtained.

[0047] (3) Use the dynamic method to coat the organic bentonite suspension from both ends of the pretreated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com