Multifunctional electromagnetic stirrer

An electromagnetic stirrer and electromagnetic stirring technology, applied in the field of continuous casting electromagnetic stirring, can solve the problems of unfavorable power grid function and stability, failure to meet process requirements, small central magnetic field, etc., and achieve simple and ingenious connection method, simple structure and small size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment one structure of the present invention

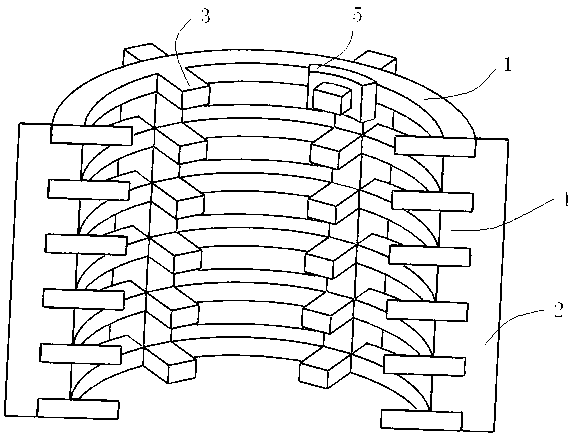

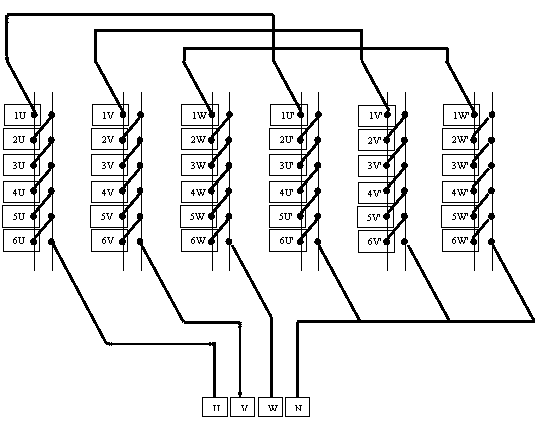

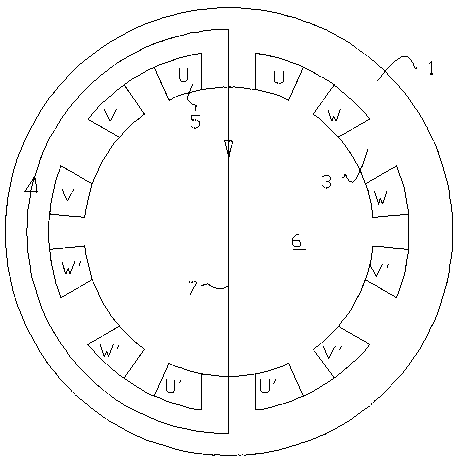

[0027] see figure 1 , is a cross-sectional schematic diagram of a multifunctional electromagnetic stirrer embodiment 1 of the present invention (the stirrer shell and other components are not shown), the multifunctional electromagnetic stirrer of the present invention includes an annular iron core 1, a rack iron core 2. Annular iron core salient pole 3, rack iron core salient pole 4 and electromagnetic coil winding 5, annular iron core 1 is horizontal, divided into six upper and lower layers at equal intervals, and the inner wall of each layer is respectively equipped with six annular iron cores. The core salient pole 3; the rack core 2 is vertically arranged, and there are six uniformly distributed on the outer circumference of the annular iron core 1, and each bar contains five equally spaced rack core salient poles 4, and the rack core 4 The salient poles of the ring iron core 1 are respectively inserted into the i...

Embodiment 2

[0033] Embodiment two structure of the present invention

[0034] Such as Figure 8 It is a cross-sectional schematic diagram of another embodiment of the multifunctional electromagnetic stirrer of the present invention. A multifunctional electromagnetic stirrer includes six layers of horizontally arranged second annular iron cores 8, six vertically arranged second rack iron cores 9 and Thirty-six identical electromagnetic coil windings 5; each of the six second rack cores 9 has six salient poles 10, and the second annular core 8 is set on the outer circumference of the second rack core 9 , the second annular iron core 8 is divided into six layers up and down, and each layer of the second annular iron core 8 corresponds to the six salient poles 10 of the second rack iron core 9; Each salient pole 10 of the bar iron core 9 is supplied with three-phase low-frequency alternating current by a variable frequency power supply.

[0035] The difference between the structure of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com