Module type high-speed mounting head for chip mounter

A placement head and modular technology, which is applied in the direction of assembling printed circuits with electrical components, can solve the problems of increased cost of placement machines, bloated placement heads, and difficulty in controlling accuracy, and achieves easy maintenance and maintenance. Replaceable, responsive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

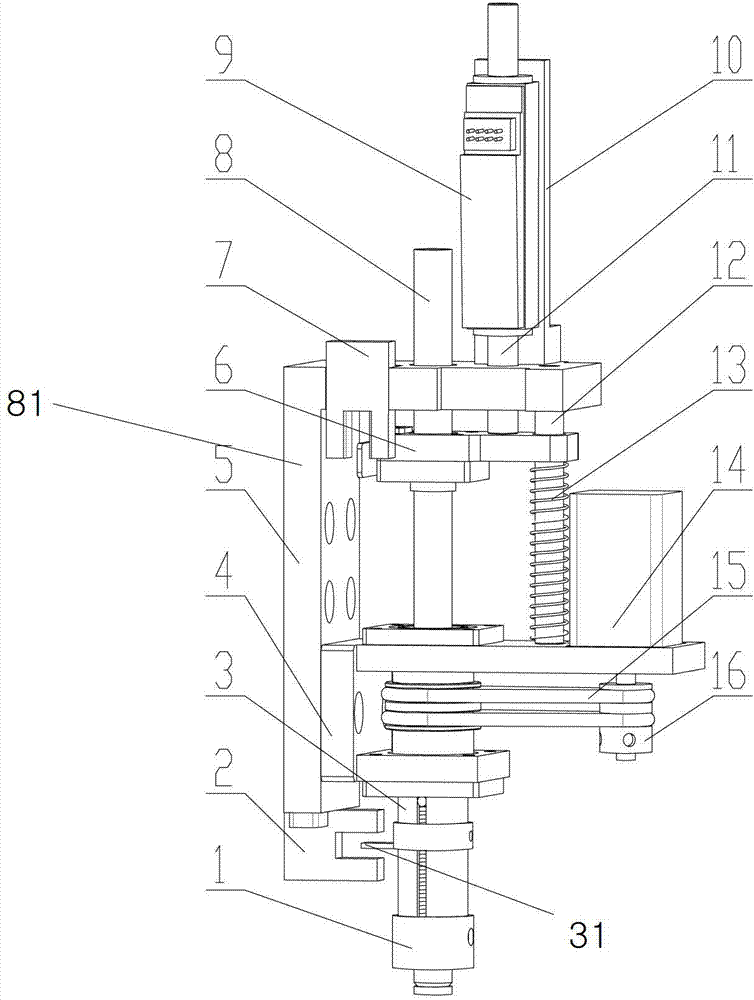

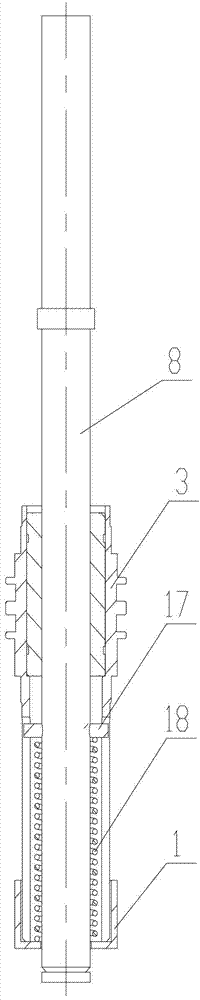

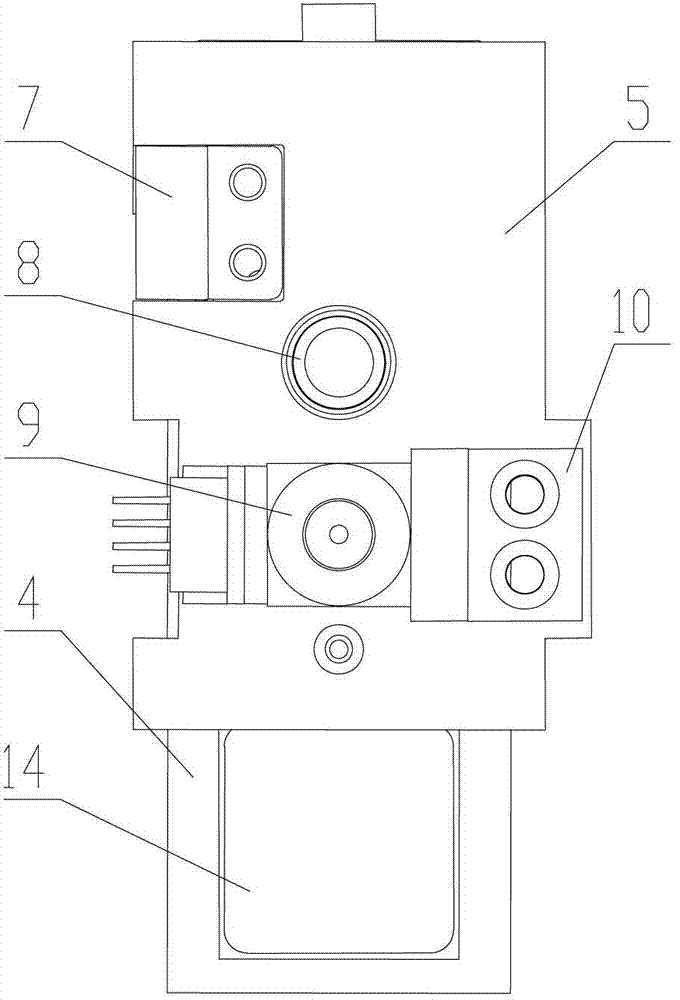

[0035] Such as figure 1 , figure 2 with image 3 As shown, the modular high-speed placement head for a placement machine of the present invention includes a placement head fixing frame 5, a pulley frame 4, a placement spindle 8, a lifting mechanism and a rotating mechanism. The placement head holder 5 is an L-shaped structure, and the two sides of the top of the L-type placement head holder 5 are respectively provided with a boss and a groove, wherein the groove and the boss are equal in width and positions correspond to each other, which can They are snapped together, which facilitates the positioning of multiple placement heads when they are mounted side by side. The pulley frame 4 is a J-shaped structure, and the pulley frame is connected to the side of the L-shaped mounting head fixing frame 5 through two hexagon socket bolts.

[0036] The lifting mechanism includes a servo linear motor 9, a linear motor push rod 11 and a pressure block 6. The above-mentioned servo lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com