Variable camber groove grinding-based high-precision ceramic ball machining equipment

A technology of processing equipment and variable curvature, which is applied in the direction of metal processing equipment, grinding devices, grinding machine tools, etc., can solve the problems of low processing precision and efficiency required by the device, and achieve the effect of good grinding size selectivity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

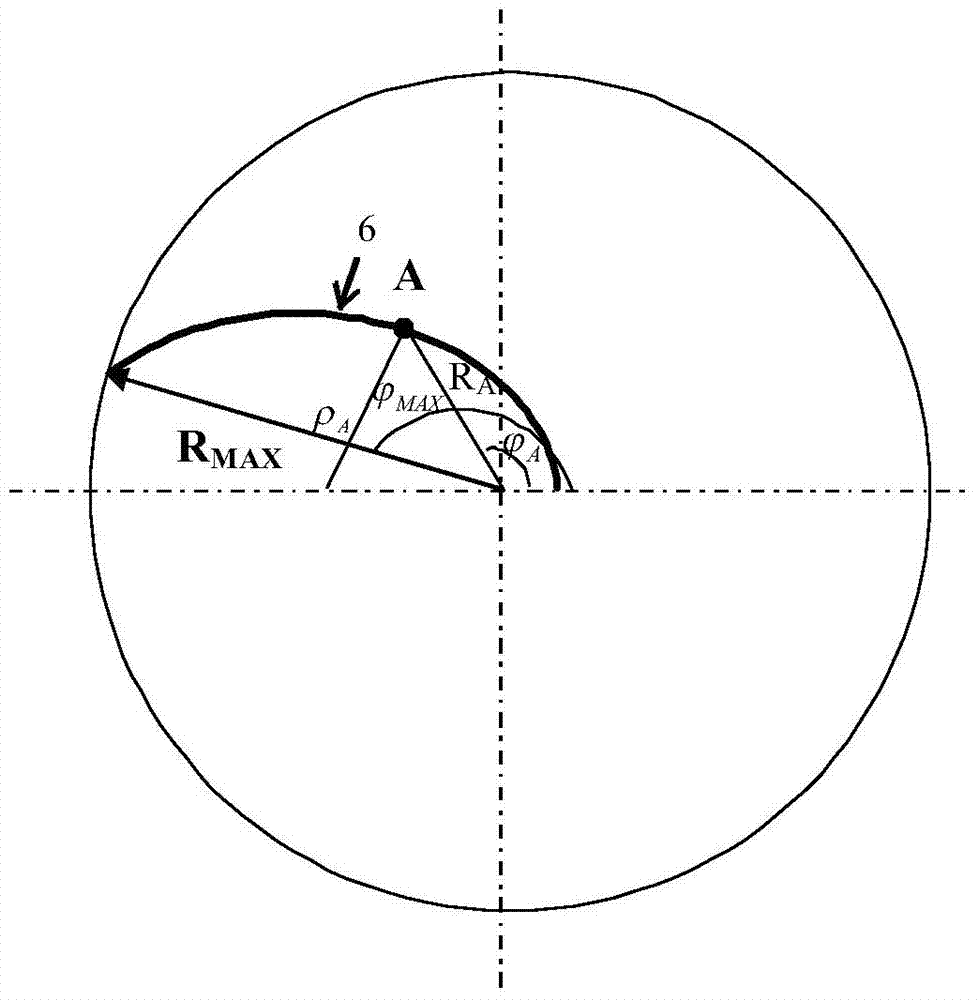

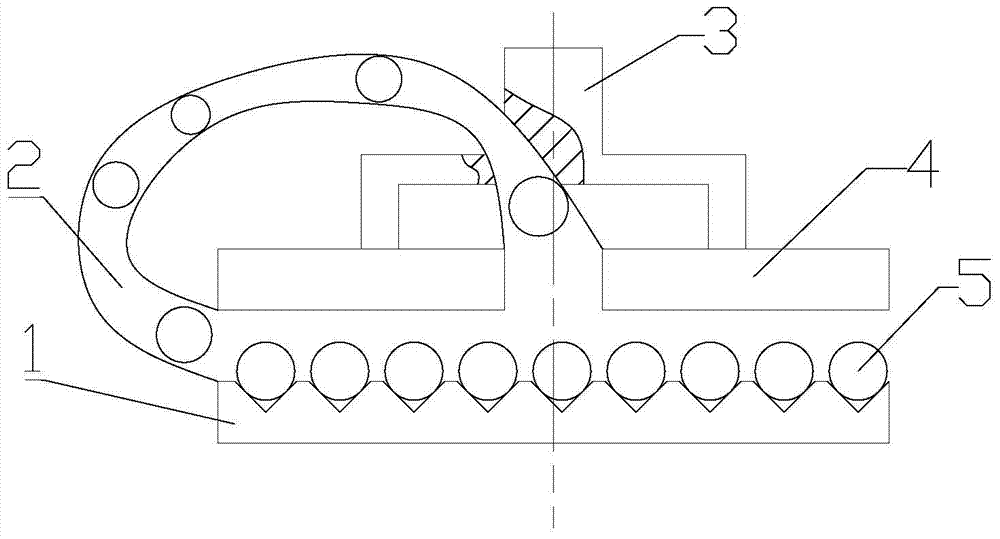

[0021] refer to figure 2 and image 3 , a high-precision ceramic ball processing equipment based on variable curvature groove grinding, the variable curvature groove is a helical V-shaped groove, including an upper grinding disc 4, a lower grinding disc 1, a workpiece circulation system 2 and a loading system 3, The upper grinding disc 4 is connected with the loading system 3; the lower grinding disc 1 is provided with a helical V-shaped groove, the entrance of the helical V-shaped groove is connected with the outlet of the workpiece circulation system 2, and the entrance of the workpiece circulation system 2 Connected to the outlet of the helical V-shaped groove, the entrance of the helical V-shaped groove is located at the center of the lower grinding disc; A processing contact point, the ceramic ball blank 5 to be processed moves in the helical V-shaped groove, and its rotation angle also changes accordingly, realizing the "relative orientation" grinding movement.

[002...

Embodiment 2

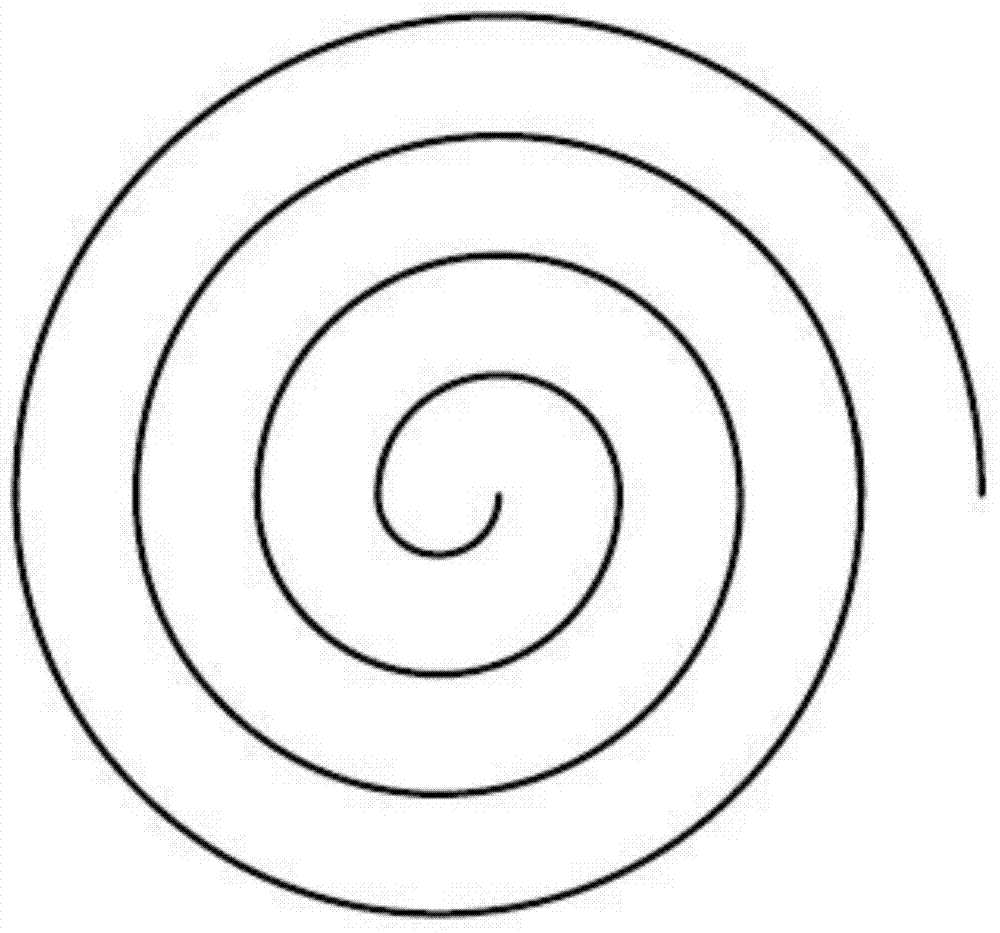

[0031] refer to Figure 4 , in this embodiment, the v-shaped groove of the lower grinding disc adopts image 3 The variable pitch helix shown. The remaining structures and implementation modes of this embodiment are the same as those of Embodiment 1.

Embodiment 3

[0033] In this embodiment, the V-shaped groove of the lower grinding disc adopts an involute groove. Of course, other variable curvature grooves can also be used

[0034] Other structures and implementations of this embodiment are the same as those of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com