Accurate one-dimensional rotary and two-dimensional tilting table

A workbench, sophisticated technology, applied in non-electric variable control, instruments, instrument parts and other directions, can solve the problems of complex transmission structure, low adjustment accuracy, slow moving speed, etc., to achieve compact and simple overall structure, dynamic response Good performance, reducing the effect of error accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

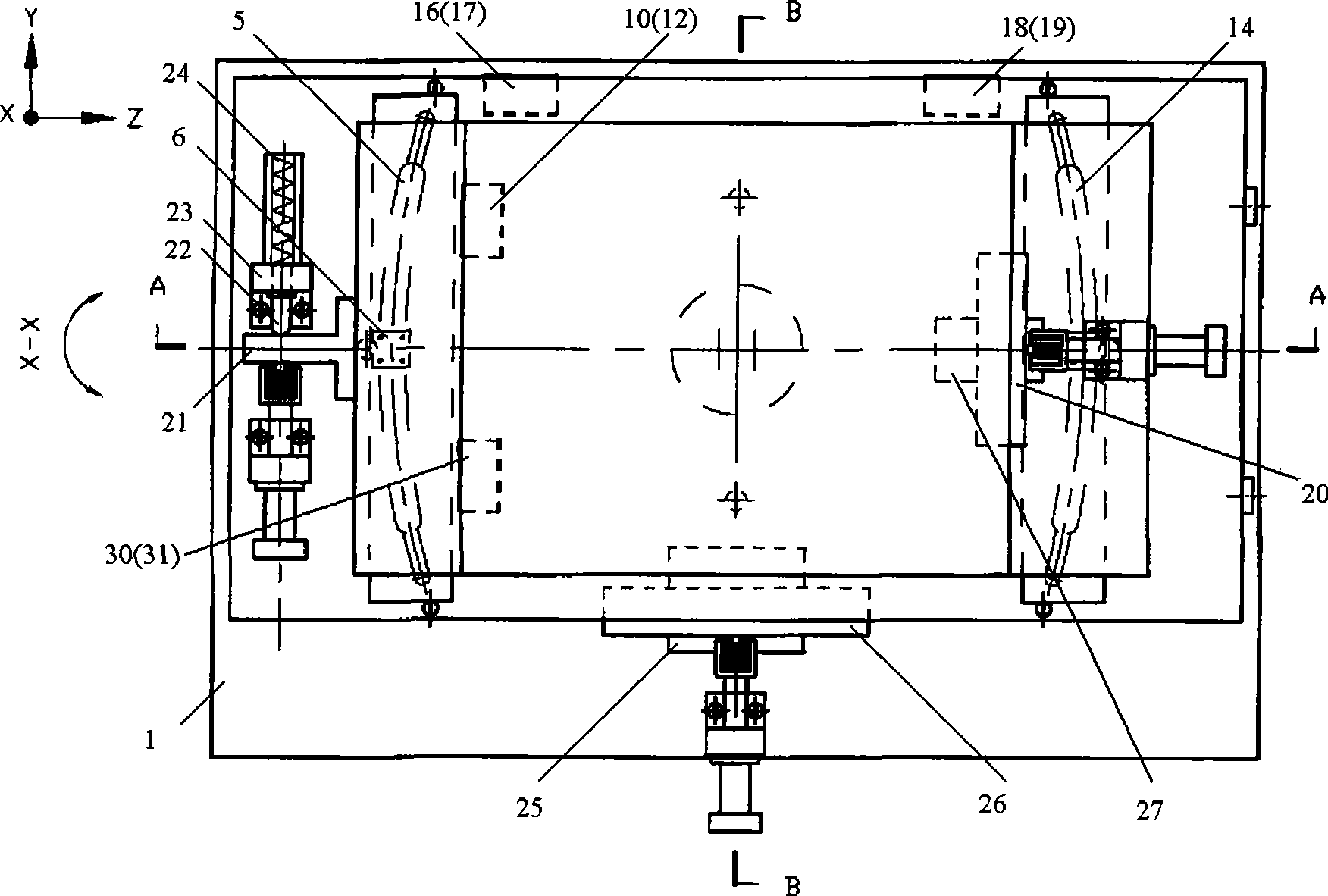

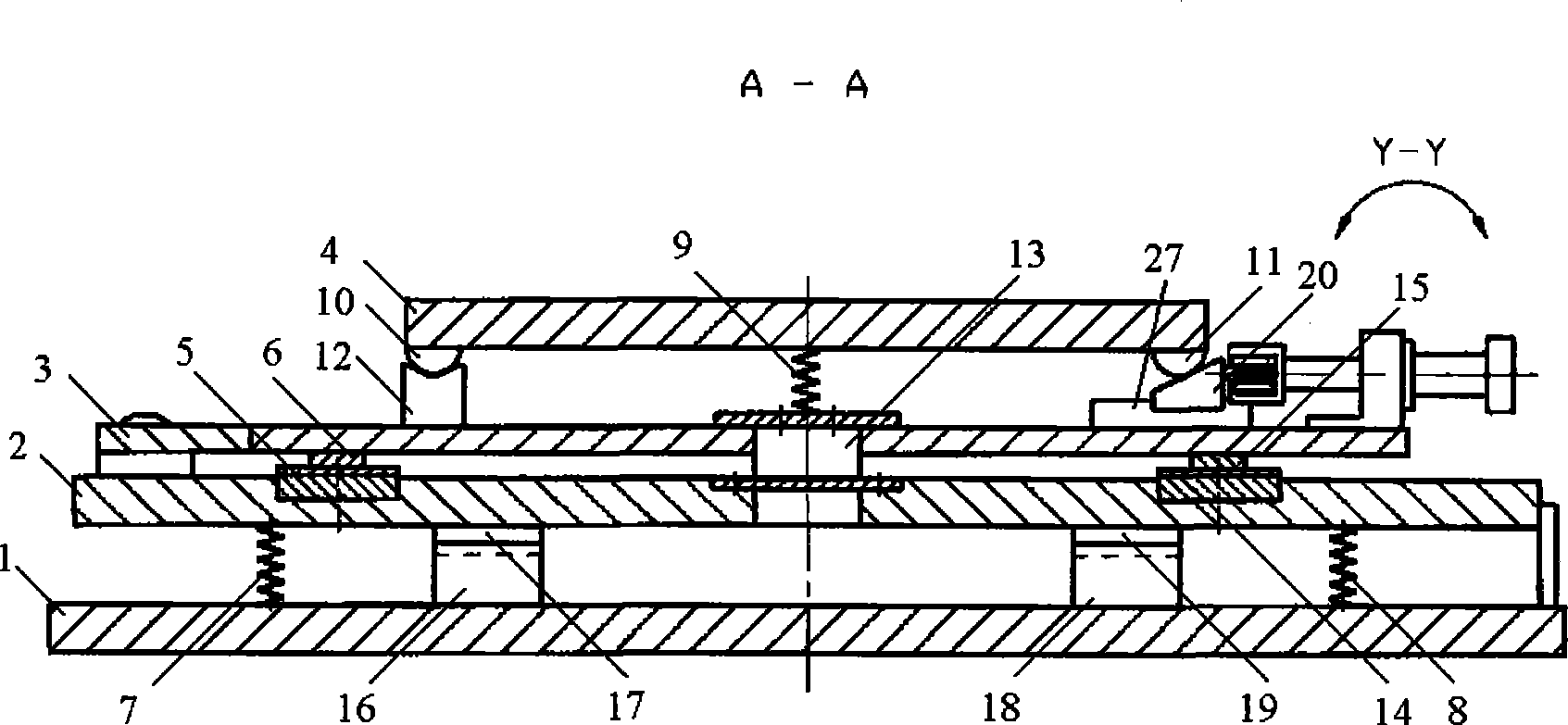

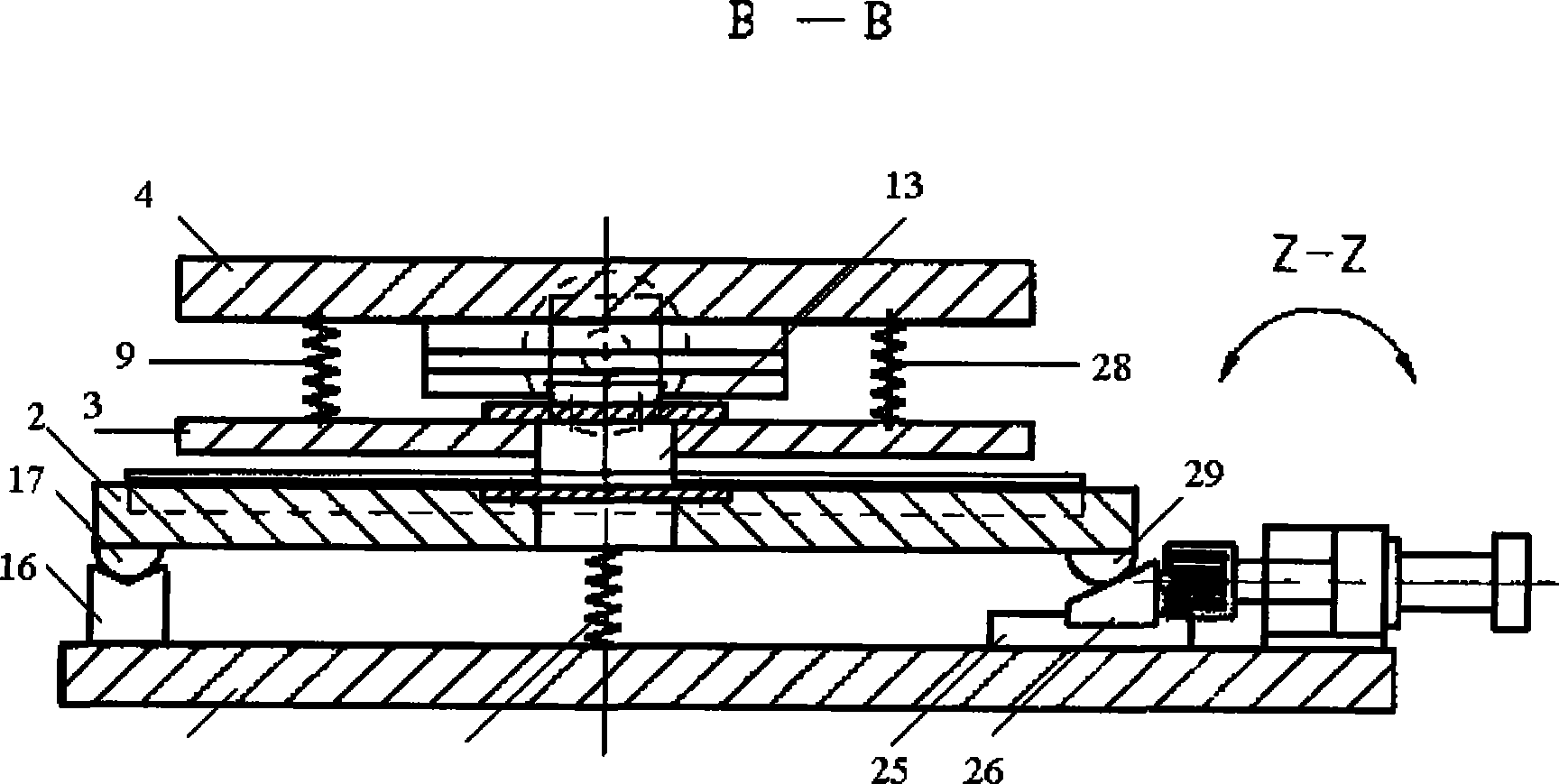

[0031] The precise three-dimensional rotating and tilting worktable of the present invention will be further described below with reference to the accompanying drawings and embodiments.

[0032] see first figure 1 , figure 2 and image 3 , as can be seen from the figure, the present invention mainly includes a base 1, a lower board 2, a middle board 3, an upper board 4, an adjustment mechanism and a driving part.

[0033] Two rotating pairs are symmetrically fixed on one side of the base 1 and are connected to the lower plate 2, and the lower plate 2 is rotated through the rotating pair. A linear guide 25 is fixed at the center position of the other side of the base 1 , and the guide slider is a wedge-shaped slider 26 . The wedge-shaped slider 26 is connected with the cylindrical body 29 on the lower board 2 in line contact. The wedge-shaped slider 26 can slide on the linear guide 25 under the action of the adjustment mechanism, lift the lower deck 2, and make the lower d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com