Valve grinder with limited processing capacity

A grinding machine and processing capacity technology, applied in grinding machine tools, grinding devices, grinding tools, etc., can solve the problems of difficult promotion, low grinding quality and efficiency, high noise, etc., to reduce the use of human resources and ensure large-scale production. The effect of production and assembly quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

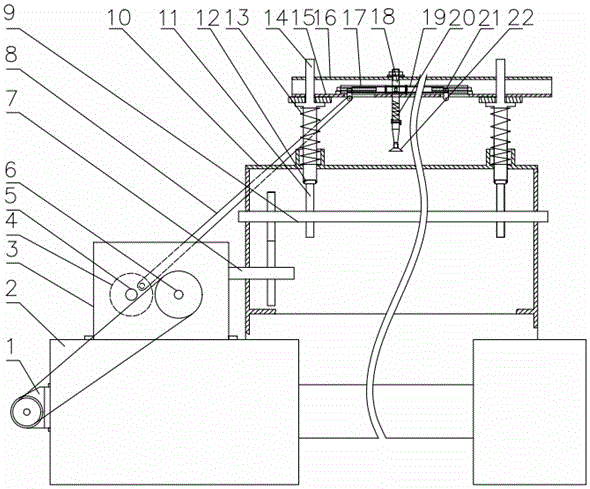

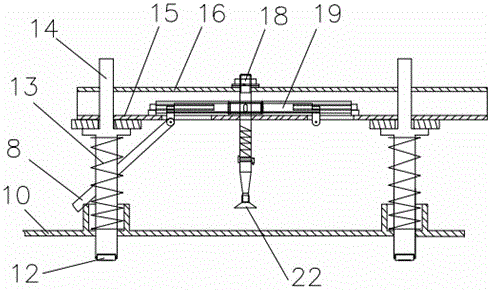

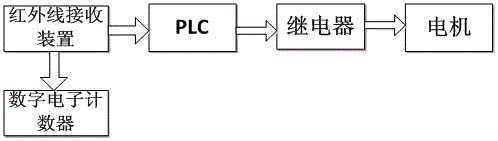

[0024] According to attached figure 1 It can be seen that the present invention specifically relates to a valve grinding machine with a limited processing capacity. Its structure is mainly composed of a frame 2, a grinding device, a liftable groove beam 15, a crank guide rod slider mechanism that drives the grinding device to rotate counterclockwise, and It is composed of a control system that limits the amount of processing. The grinding device is used to reprocess the engine valve. The grinding device is installed on the channel beam 15 that can be lifted and placed horizontally. In the middle of the channel beam 15, there is a The rack plate 19, the rack plate 19 cooperates with the pinion on the grinding device, and one end of the rack plate 19 is connected with the crank guide slider mechanism provided on the frame 2, and the frame 2 is also provided with a limited grinding wheel. Processing volume control system.

[0025] The working principle of the valve grinding mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com