Micro-motion stepless speed regulation grinding device for common big vertical lathe

A technology of stepless speed regulation and large vertical lathe, which is applied to the grinding drive device, grinding frame, grinding bed and other directions, which can solve the problem that the feed accuracy of the tool rest is not enough. and other problems, to achieve the effect of wide grinding range, economical and practical, and great use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

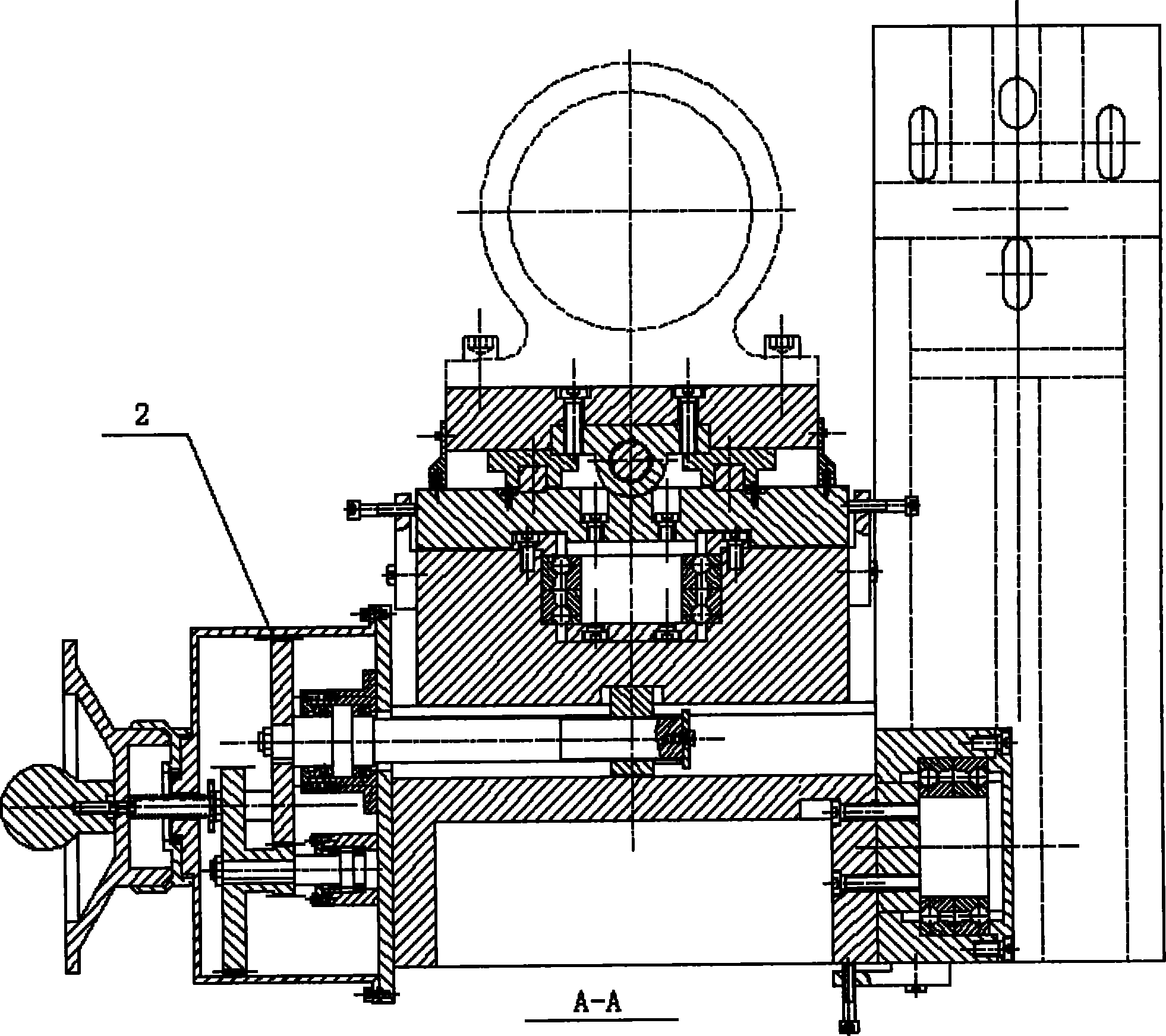

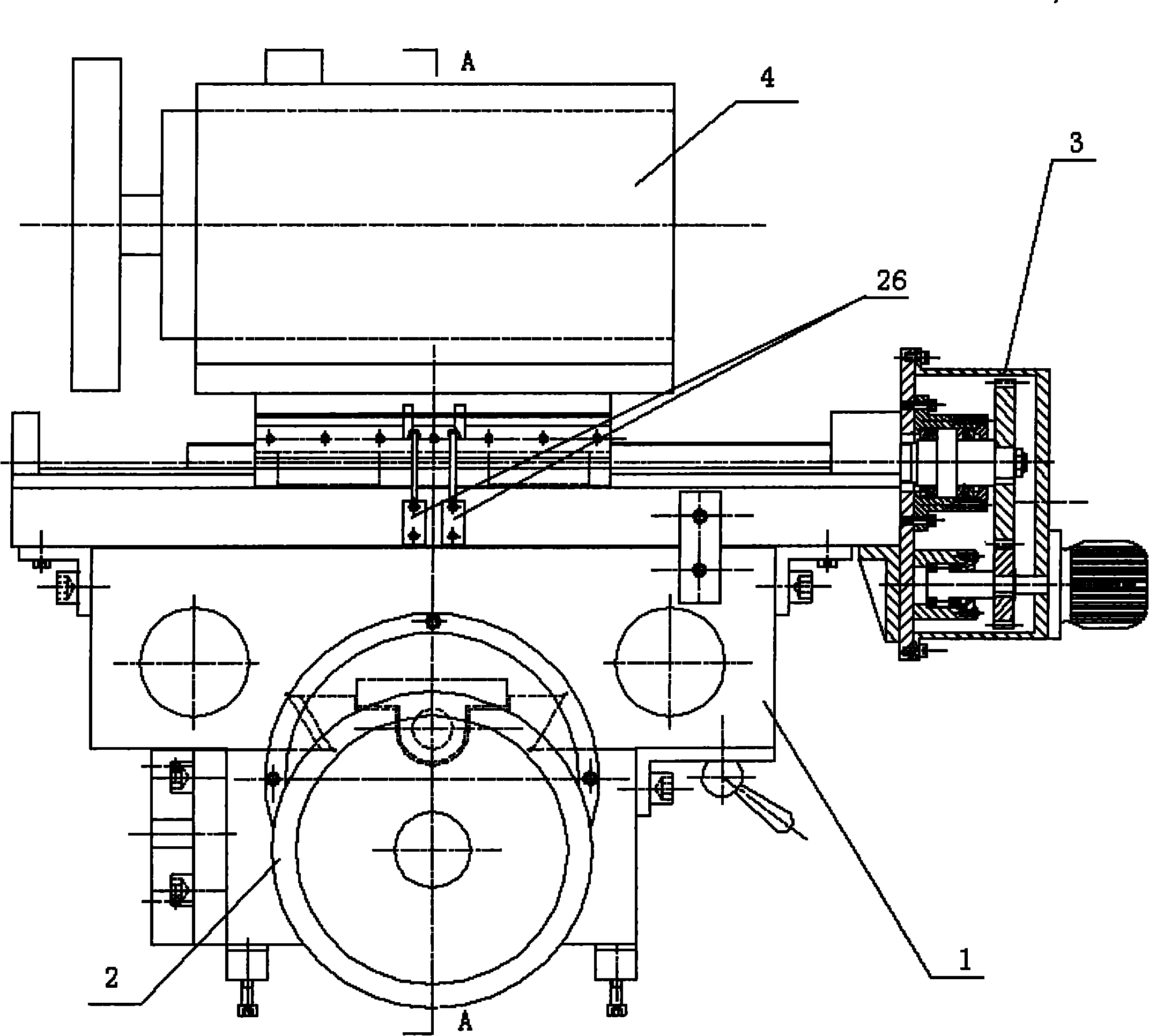

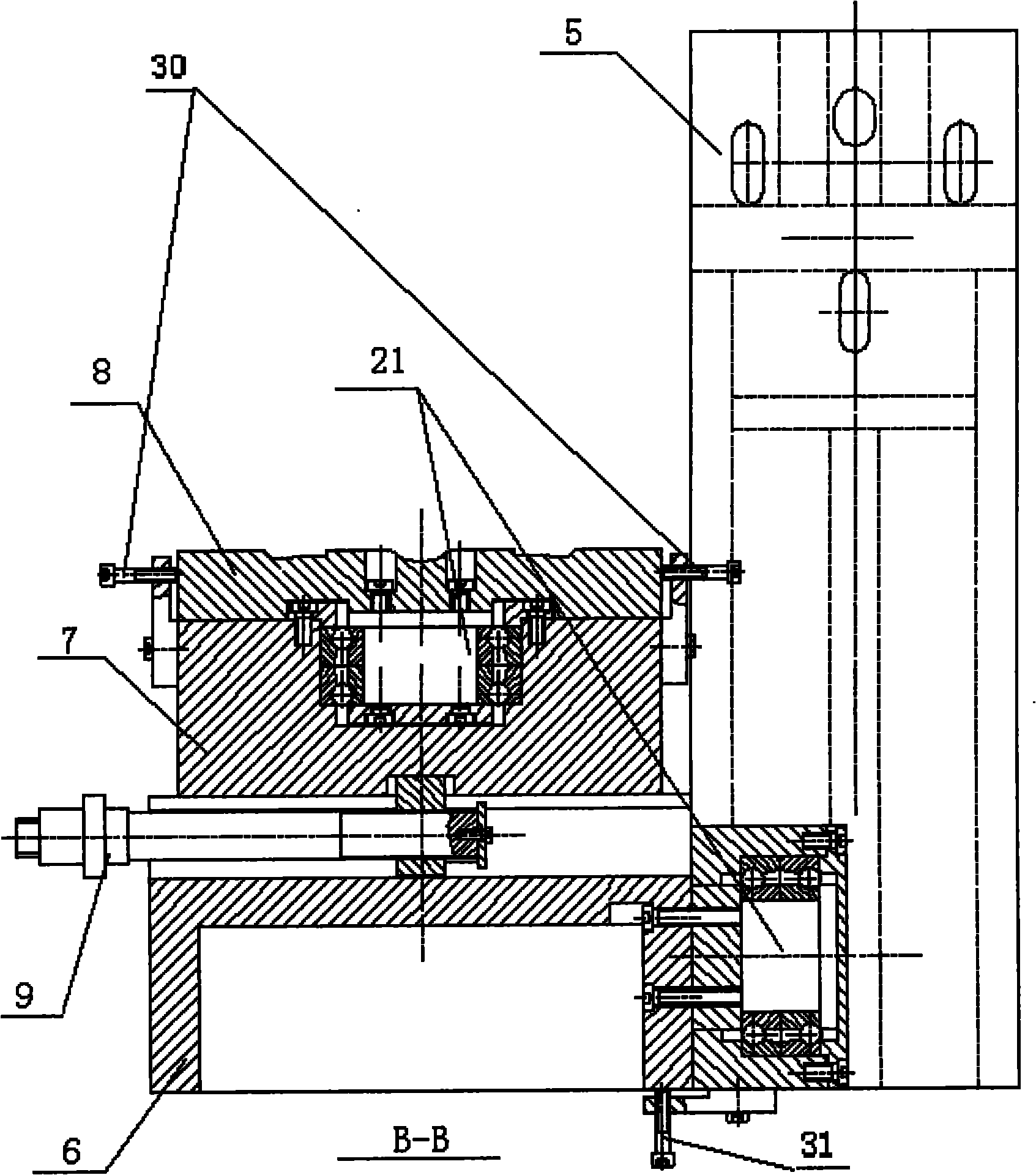

[0023] Such as figure 1 , 2 , 3, and 4, the two-dimensional adjustment mechanism 1 is composed of two pairs of rotary bearing pairs 21 and a pair of dovetail pairs 22 to form the support body 5, the first connecting body 6, the second connecting body 7 and the guide rail mounting plate 8, the supporting body 5 The outer ring of a pair of angular contact bearings is fixed through the bearing seat and the bearing end cover, and the first connecting body 6 is connected and fixed by a shaft to the inner ring of the angular contact bearing, so that the first connecting body 6 rotates back and forth relative to the support body 5, The adjusting screw 31 rotates the first connecting body 6, and the locking after the rotation adjustment utilizes the elastic deformation between the supporting body 5 and the first connecting body 6, and is locked with the screw of the locking mechanism 32; the first connecting body 6 and The second connecting body 7 is connected through its own doveta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com