Grinding device of welding gun electrode rod

A technology of electrode rod and dresser, which is applied in the direction of electrode characteristics, electrode maintenance, etc., and can solve the problems of resource waste, cost, and height increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

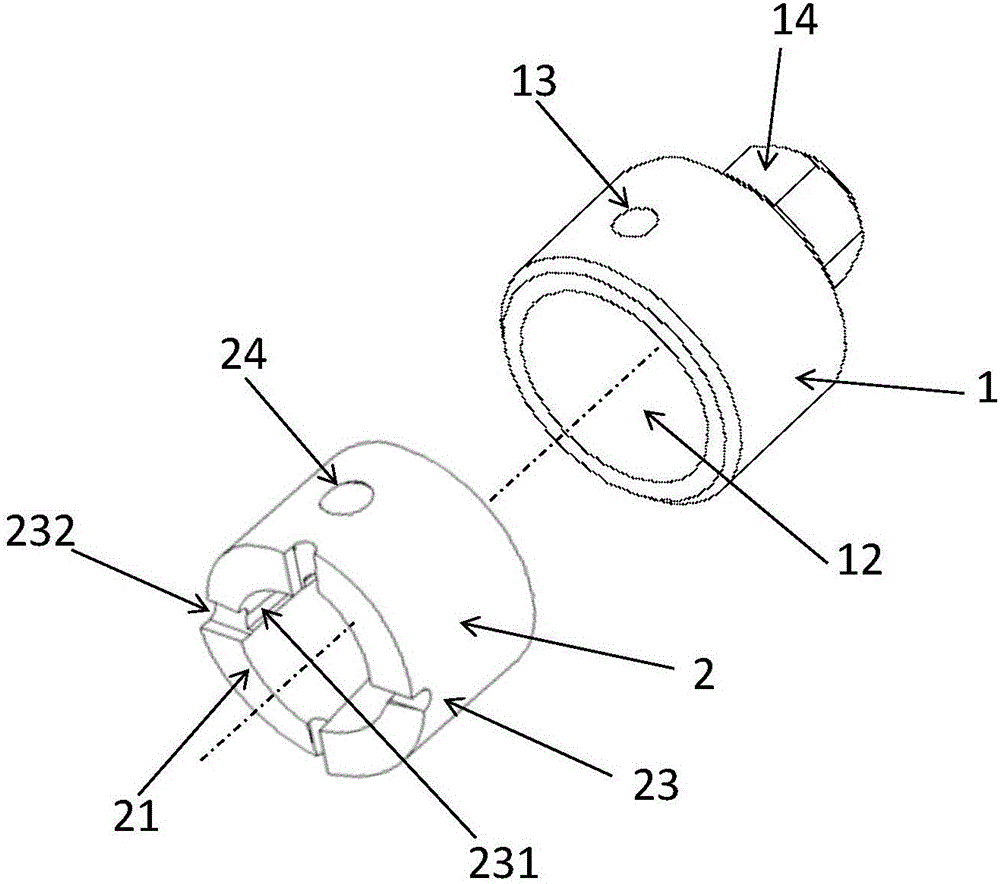

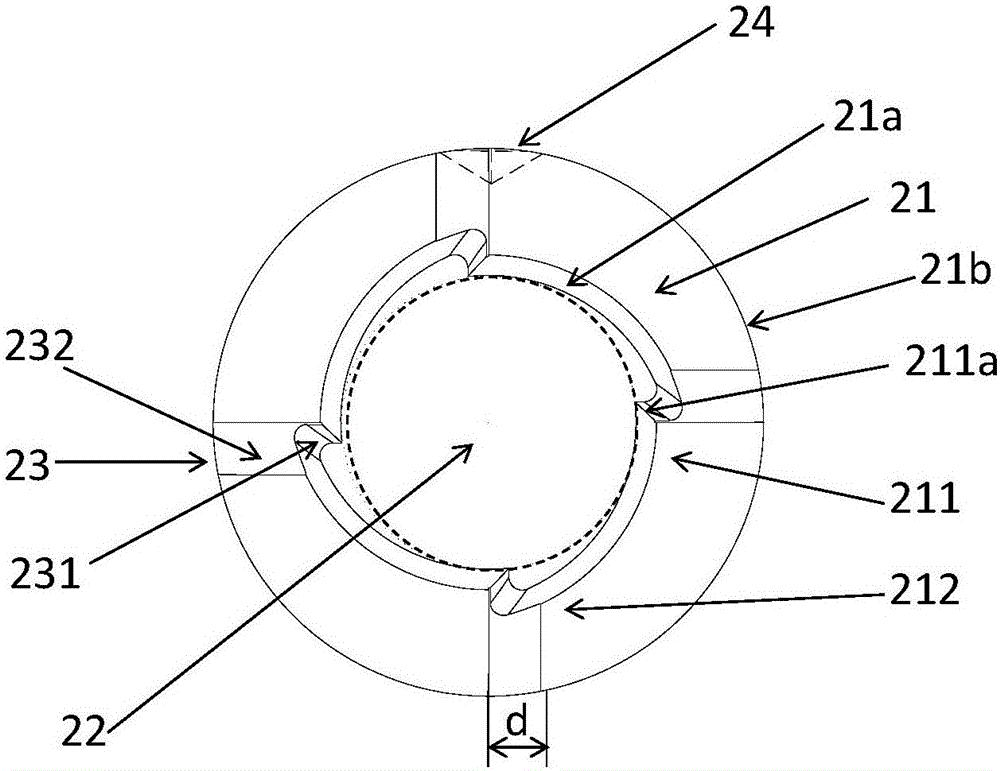

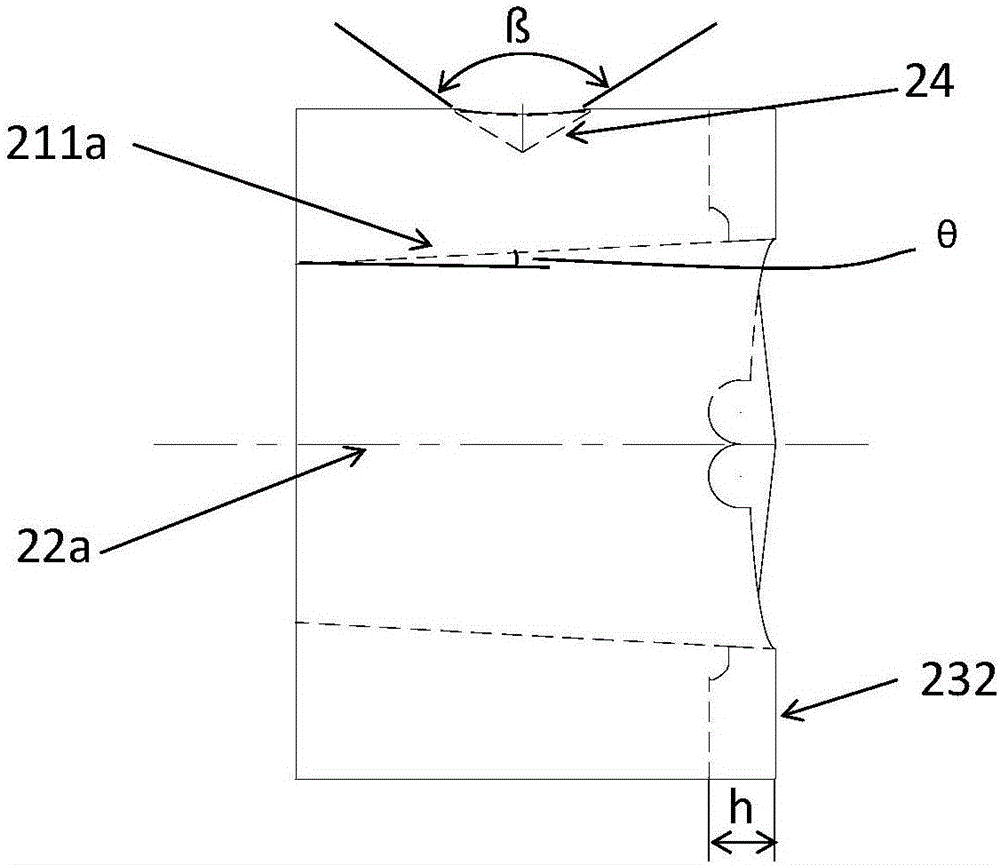

[0024] like figure 1 and 2 As shown, a dresser for a welding torch electrode rod according to a preferred embodiment of the present invention includes a tool holder 1 and a cutter 2. One end of the cutter holder 1 is provided with a cutter installation groove 12, and the cutter 2 is fixedly installed in the cutter installation groove. 12, so that the cutter 2 can rotate synchronously with the knife seat 1, the cutter 2 includes several arc-shaped blades 21, the several arc-shaped blades 21 are distributed in a circle and its long arc side is its outer wall 21b, and the short arc side Its inner side wall 21a, thereby forms electrode rod grinding hole 22 in the central pos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com