Automobile metal pipe mold smoothening and grinding device

A metal pipe and mold technology, which is applied in the field of automotive metal pipe mold leveling and grinding devices, can solve the problems of not being able to meet the needs of users, affecting the quality of mold leveling, and poor mold flatness, so as to prevent pollution, improve flatness, and maintain cleanliness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

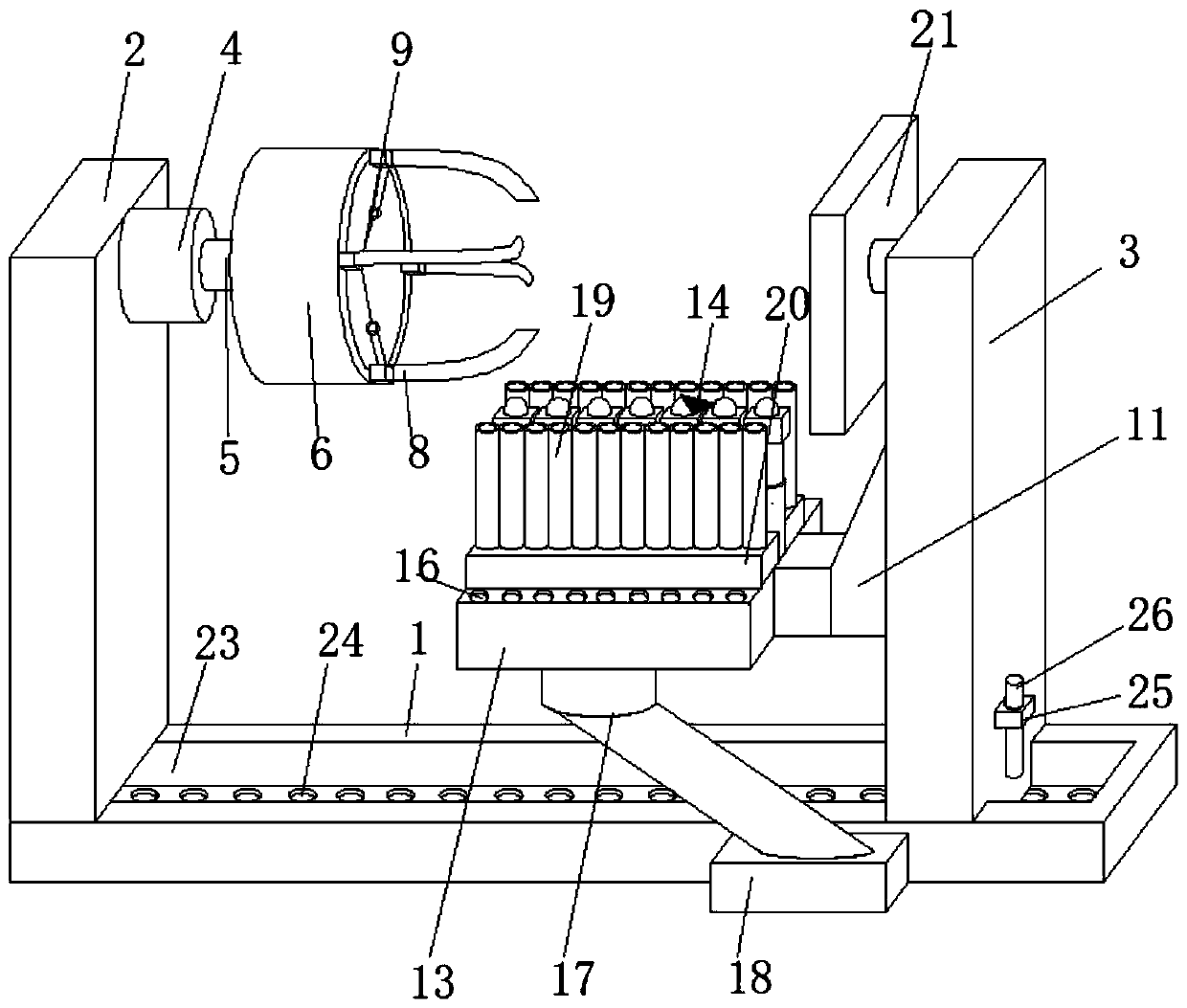

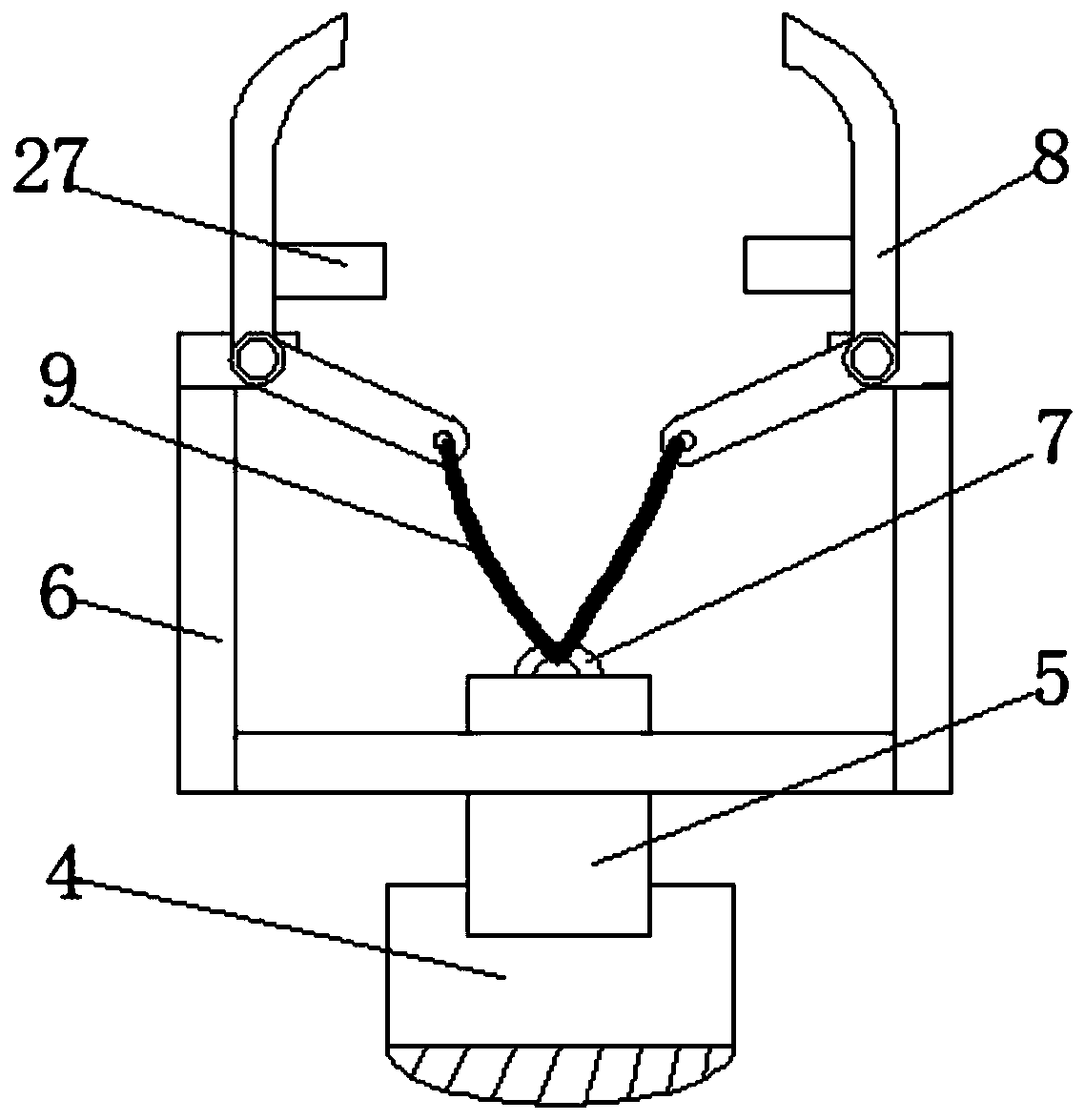

[0033] refer to Figure 1-2 , a kind of flat grinding device for automobile metal pipe molds, including a base 1, the top of the base 1 is connected with a first fixed plate 2 and a second fixed plate 3 along the horizontal direction, the top of the first fixed plate 2 is close to the bottom of the second fixed plate 3 One side is connected with a rotary motor 4, the output end of the rotary motor 4 is connected with a horizontal shaft 5, the end of the horizontal shaft 5 away from the rotary motor 4 is connected with a bushing 6 through a bearing, and the end of the horizontal shaft 5 passing through the bearing is connected with a tie ring 7 One end of the casing 6 away from the horizontal shaft 5 is hinged with four symmetrically distributed fixed claws 8, and an adjustment steel rope 9 is connected between the two opposite fixed claws 8, and the center of the adjustment steel rope 9 is connected to the tie ring 7 When in use, by controlling the rotating motor 4 to work, th...

Embodiment 2

[0035] refer to Figure 1-4, a flat grinding device for automobile metal pipe molds, which is basically the same as that of Embodiment 1, furthermore, a first limiting chute 10 is provided on the side of the second fixing plate 3 close to the first fixing plate 2, and the first limiting chute 10 is provided. Slide block 11 is slidably connected in position chute 10, and the cross section of slide block 11 is trapezoidal, and two electric telescopic rods 12 are connected between slide block 11 and the inner wall of first limit chute 10, and slide block 11 is away from the second One side of the fixed plate 3 is connected with a fixed base 13 , and the top of the fixed base 13 is connected with a grinding assembly 14 arranged horizontally.

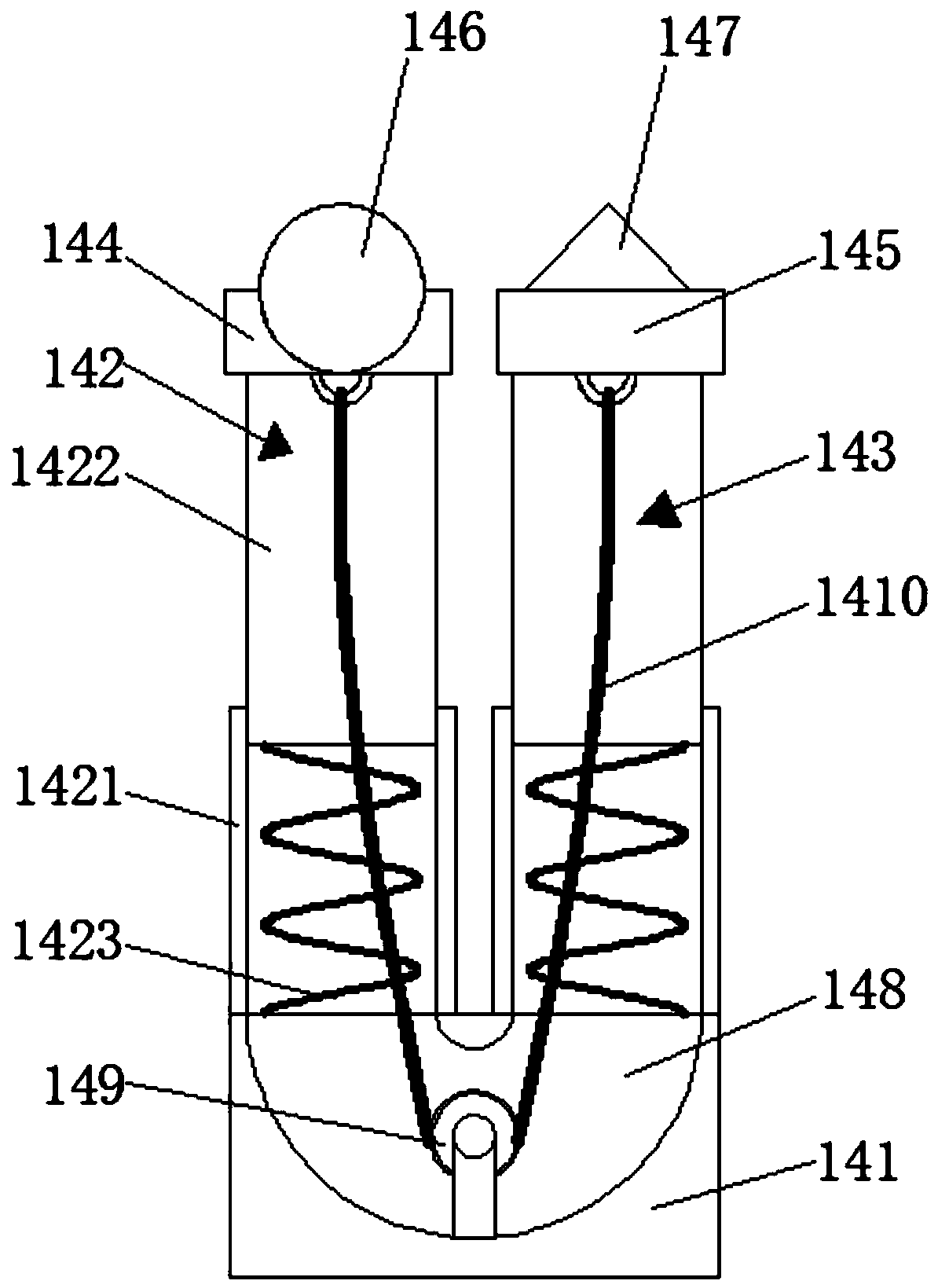

[0036] The grinding assembly 14 includes a mounting base 141, a first adjusting rod 142 and a second adjusting rod 143, and the first adjusting rod 142 and the second adjusting rod 143 are all connected to the mounting base 141, and the firs...

Embodiment 3

[0040] refer to figure 1 and Figure 6 , a flat grinding device for automobile metal tube molds, which is basically the same as that of Embodiment 2, furthermore, the inner cavity of the fixed seat 13 is hollow, and two groups of symmetrically distributed negative pressure fans 15 are connected to the inner wall of the bottom of the fixed seat 13. The top of the seat 13 is provided with uniformly distributed absorption holes 16, the bottom of the fixed seat 13 is connected with a feed pipe 17, and the side of the feed pipe 17 far away from the fixed seat 13 is connected with a collection box 18, which is dissipated during the polishing process of the grinding blade 147. The grinding debris is collected to prevent pollution and affect the accuracy of grinding, while maintaining the cleanliness of the environment and improving work safety.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com