Colloid mill and production line

A colloid mill and abrasive technology, which is applied in grain processing, optical device exploration, etc., can solve the problem that the abrasive material of the moving mill cannot be found in time, and achieve the effect of improving production quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

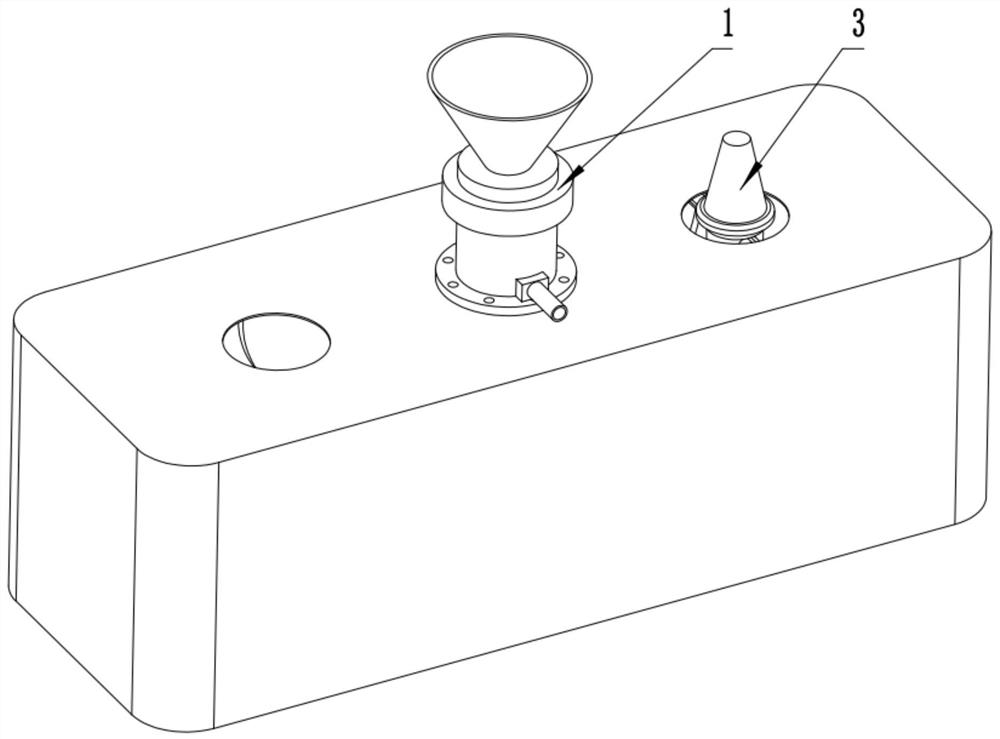

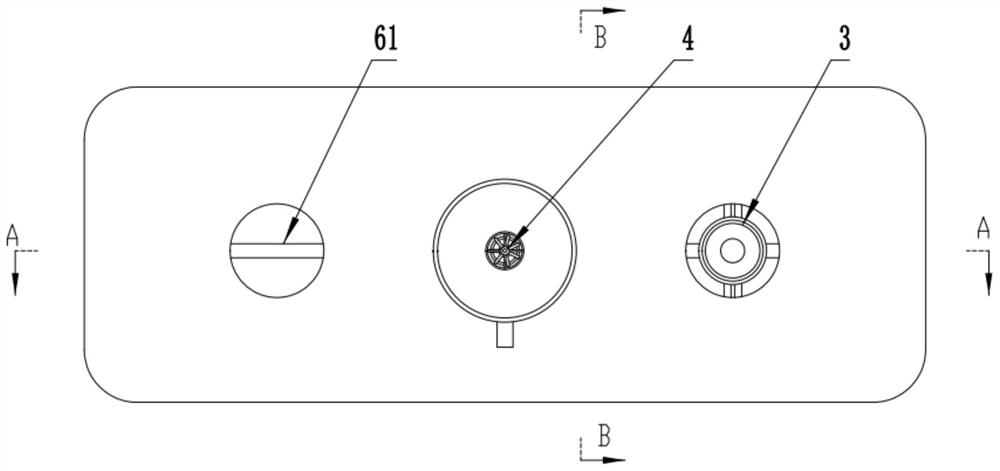

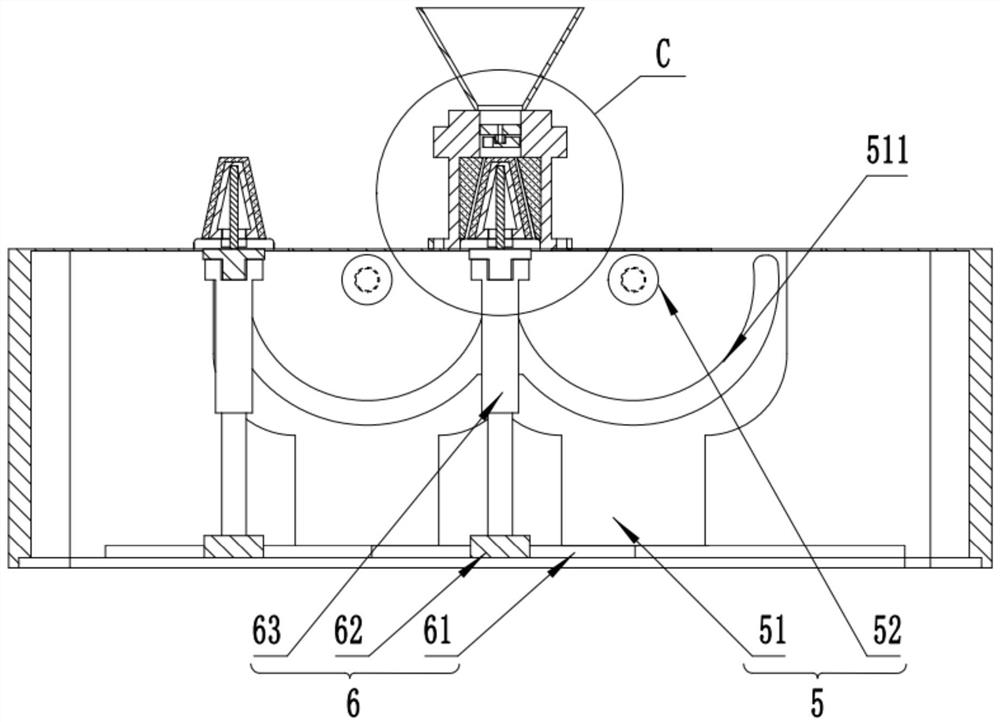

[0040] The colloid mill provided in the embodiment of the present invention is used in the field of food processing, specifically for processing the particles of collagen tripeptide solid beverages, and can also be used in the production of other granular foods, drinks or cosmetics. It has a moving grinding disc 3 The self-checking function can detect the falling off of the movable grinding disc 3 in time, which can improve the product quality.

[0041] Such as figure 2 , image 3 and Figure 5 As shown, the colloid mill of the present embodiment comprises a base and a colloid mill fixing seat 1 fixedly connected to the base, and a cavity is provided in the colloid mill fixing seat 1; a static grinding disc 2 and a moving grinding disc are arranged in the cavity 3. A grinding chamber is formed between the static grinding table 2 and the moving grinding table 3; the static grinding table 2 is fixedly connected to the colloid mill fixing seat 1, and the moving grinding table ...

Embodiment 2

[0062] This embodiment provides a production line, including the colloid mill in Embodiment 1, upstream equipment inputting raw materials to the colloid mill, and downstream equipment receiving ground raw materials from the colloid mill. The specific structure and beneficial effects of the colloid mill are described in the first embodiment, and the modification of the colloid mill is cited in this embodiment, which has the same beneficial effect.

[0063] To sum up, the production line of this embodiment can detect in time the situation that the abrasive material falls off in the dynamic grinding disc 3 in the colloid mill, and remove the dynamic grinding disc 3 in time and put it into a normal dynamic grinding disc 3, thus ensuring the production quality , improving production efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com