Dressing disk system, chemical mechanical polishing device and method for detecting falling off of dressing disk

A technology of chemical machinery and grinding devices, which is applied in the direction of abrasive surface adjustment devices, grinding/polishing equipment, and grinding machine parts, etc. It can solve the problem that the trimming disc falls off and cannot be detected, and achieves intuitive test signals and simple implementation methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

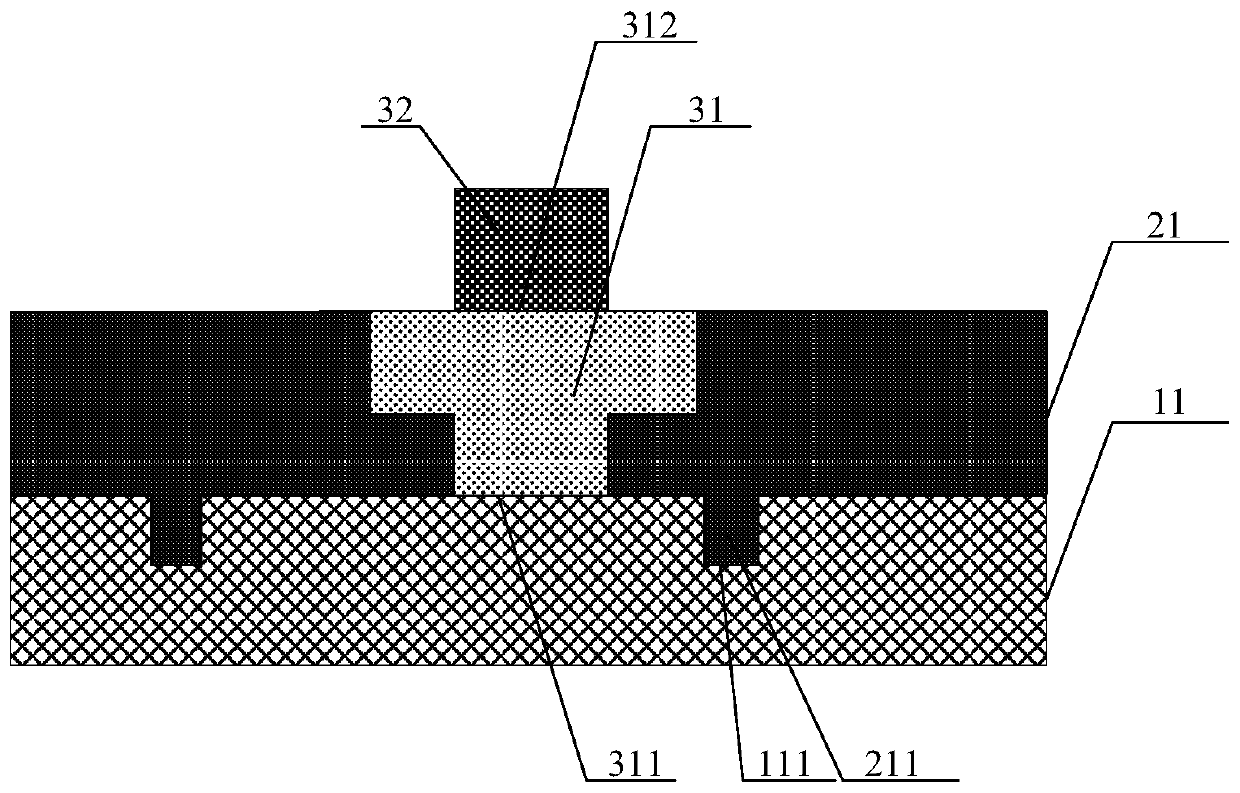

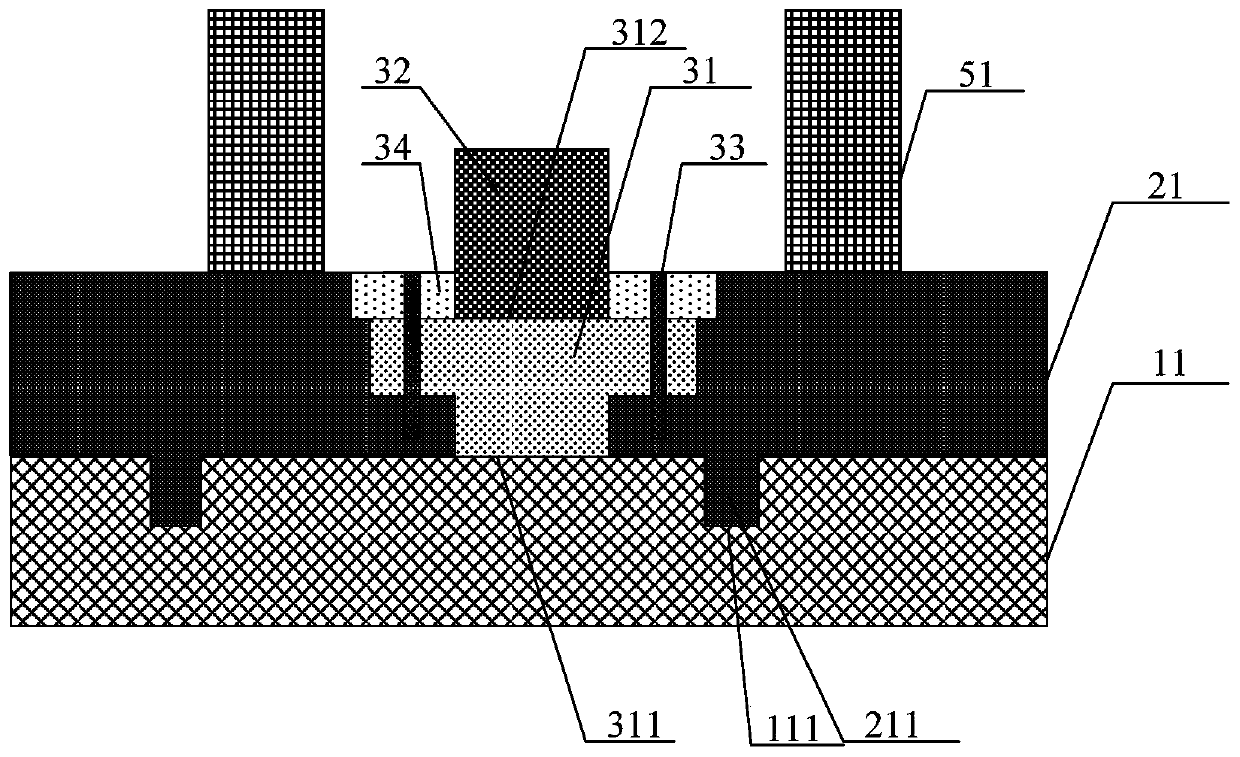

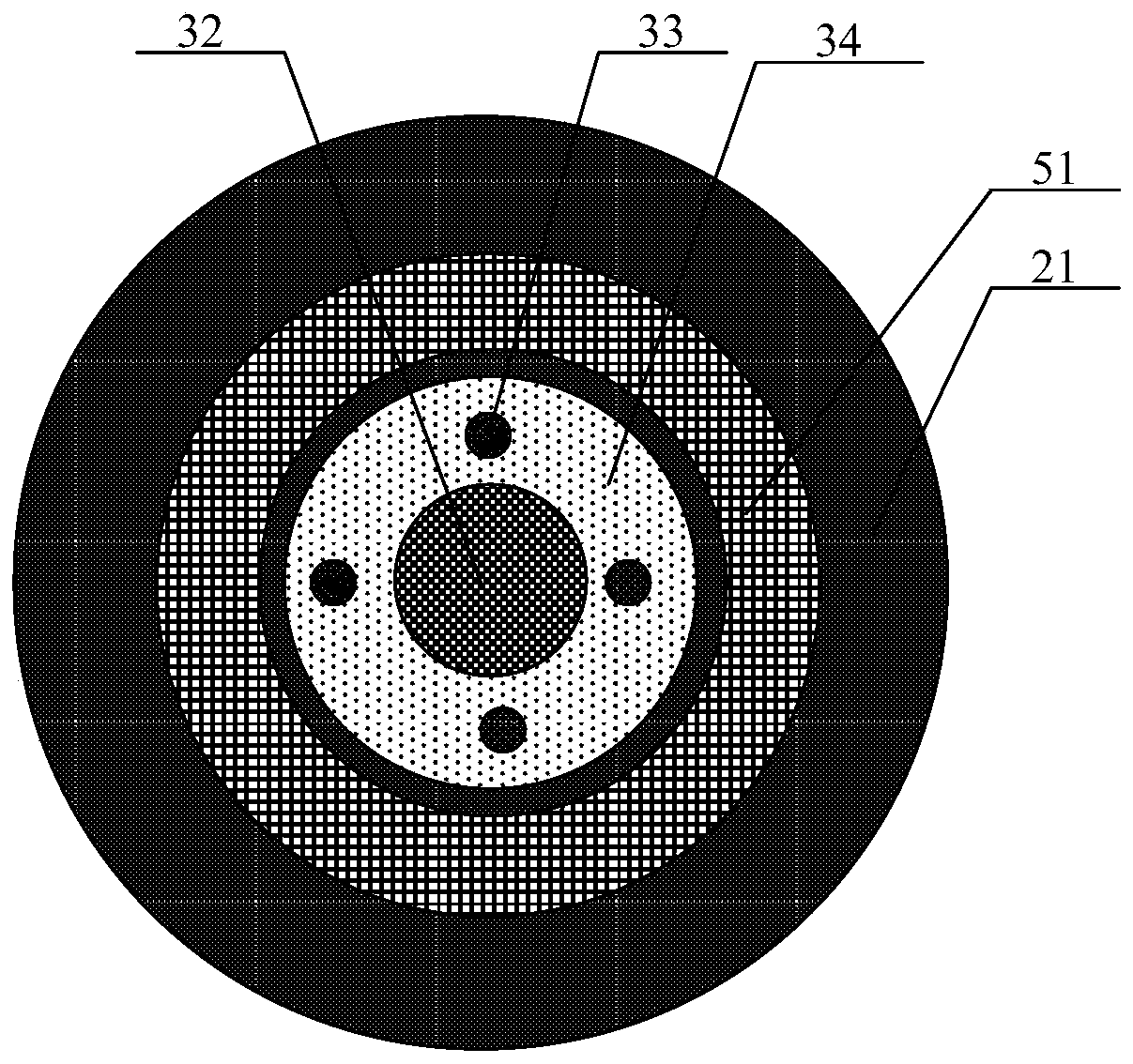

[0063] like Figure 1~5 As shown, the present invention provides a dressing disc system that can detect the dressing disc falling off during the grinding process, including:

[0064] Dressing disc 11, used for dressing the grinding pad during the grinding process;

[0065] a fixed disk 21, located above the trimming disk 11, and fixed to the trimming disk 11; and

[0066] The detection system includes an insulating part 31 and a sensor assembly 32. The insulating part 31 is arranged in the fixed plate 21 and has a first surface 311 and a second surface 312 opposite to each other. The first surface 311 and the trimming The discs 11 are in contact, the sensor assembly 32 is disposed on the second surface 312 , and the detection system is used to detect the falling off of the trimming disc 11 .

[0067] Specifically, the present invention improves the original system on the basis of the original trimming disc system by improving the trimming disc system to add a detection syste...

Embodiment 2

[0085] like Figure 5 As shown, the present invention also provides a chemical mechanical polishing device, comprising:

[0086] Grinding table 61;

[0087] A grinding pad 71, located on the upper surface of the grinding table 61;

[0088] The polishing head 81 is located on the upper surface of the polishing pad 71, and is used to chemically mechanically polish the wafer 9 to be polished between the polishing head 81 and the polishing pad 71; and

[0089] The trimming disc system is located on the upper surface of the grinding pad 71, and the trimming disc system is the trimming disc system that can detect the trimming disc falling off during the grinding process as described in any one of the first embodiment.

[0090] Specifically, this embodiment provides a chemical mechanical polishing device for a wafer, including the trimming disc system described in any one of the embodiments. In the process of carrying out chemical mechanical polishing to the wafer, the polishing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com