Signal emission warning device based on magnetic induction system to monitor forklift shovel tooth shedding

A signal emission and warning device technology, applied in the field of signal emission warning devices, can solve problems such as unsatisfactory monitoring results, damage to crusher roller teeth and deceleration system components, economic losses, etc. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with specific examples and accompanying drawings.

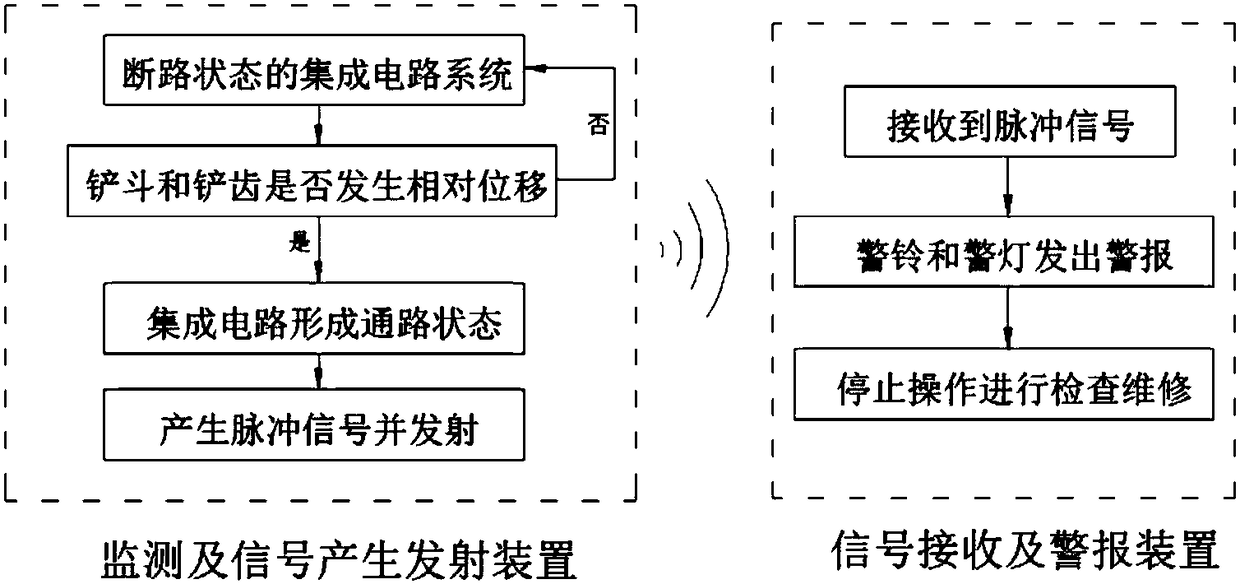

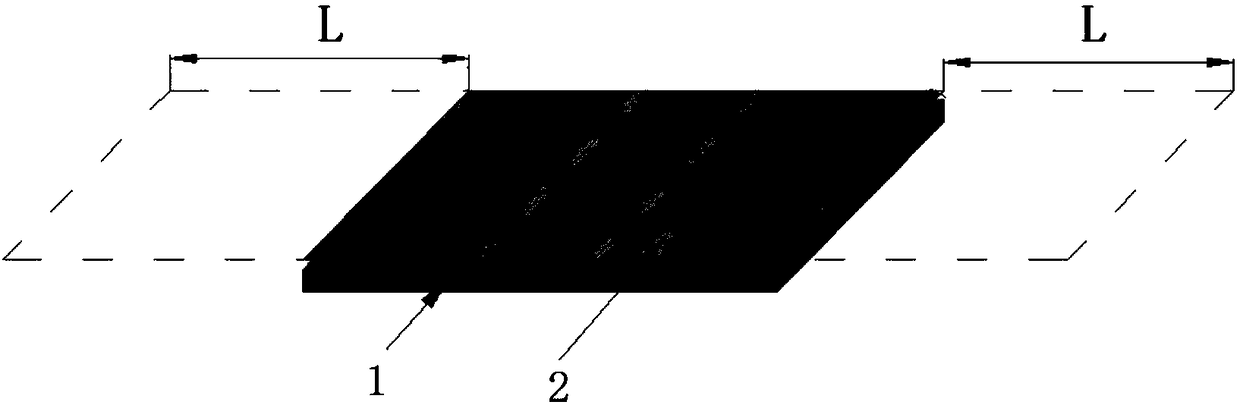

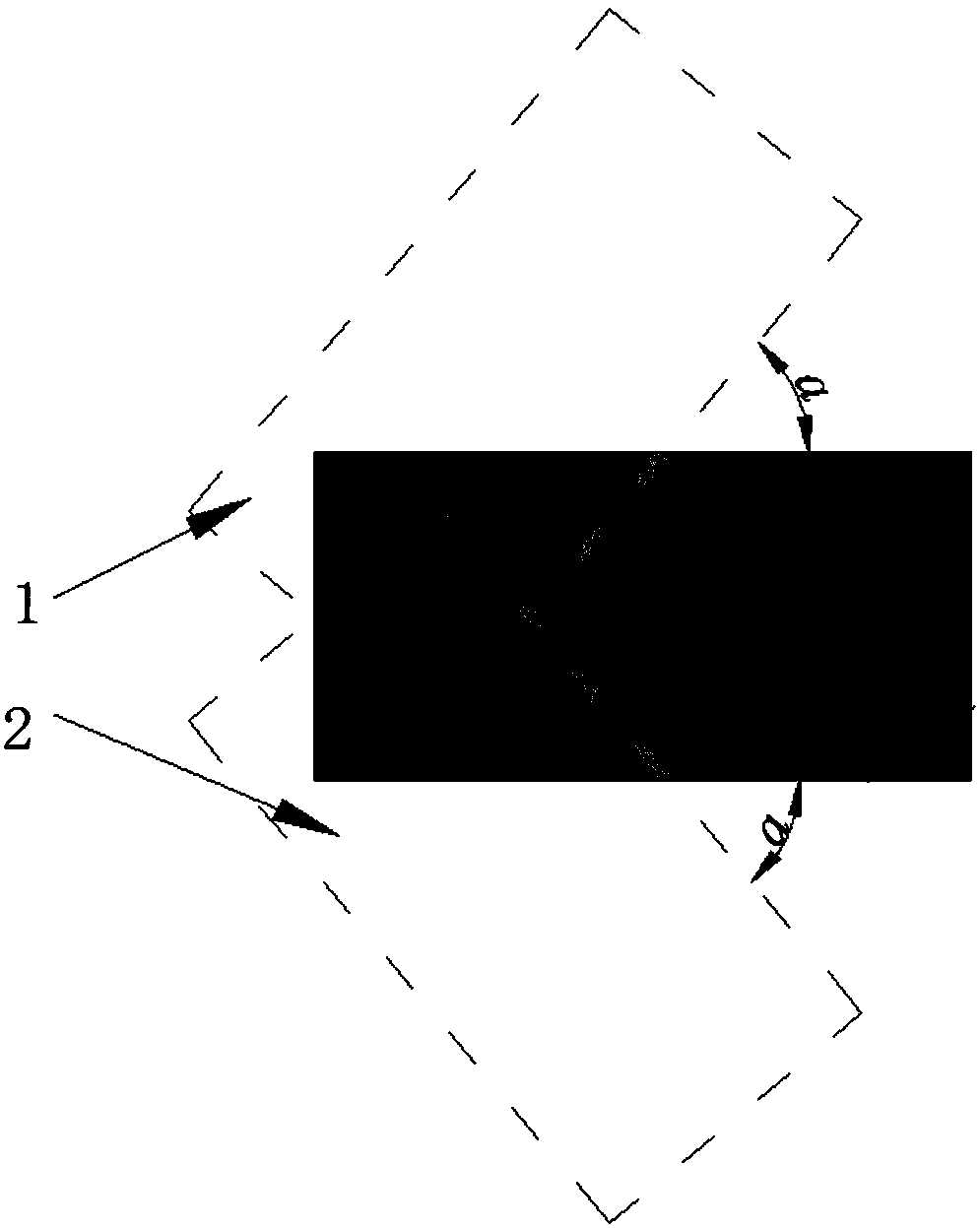

[0025] The invention provides a signal emission warning device based on a magnetic induction system for monitoring the shedding of forklift teeth, such as figure 1 and Figure 4 As shown, it includes a trigger circuit loop composed of a power supply, a signal generator 8 and a magnetic induction switch. The signal generator 8 is connected to a signal transmitting end 9; The contact 3, the first electromagnetic sheet 1, and the second electromagnetic sheet 2 between the contact 3 and the first electromagnetic sheet 1; when the shovel teeth are normally connected to the bucket 6, the second electromagnetic sheet 2 is An electromagnetic sheet 1 is adsorbed to disconnect the trigger circuit; when the shovel tooth and the bucket 6 are relatively displaced or rotated, as figure 2 and image 3 As shown, the reduction of the contact area between the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com