Tube Fixing Fixtures for Tube Expansion Equipment

A technology for fixing fixtures and equipment, applied in heat exchange equipment, metal processing equipment, positioning devices, etc., can solve problems such as damage to equipment and finished products, achieve the effect of improving stability and reliability, and avoiding reverse push equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

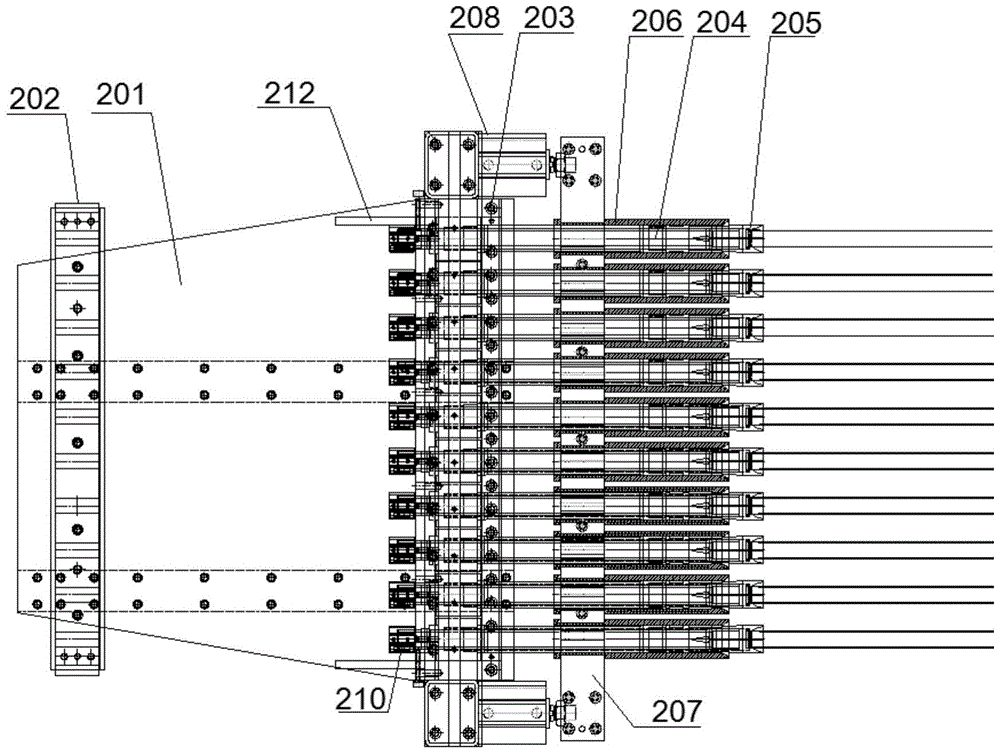

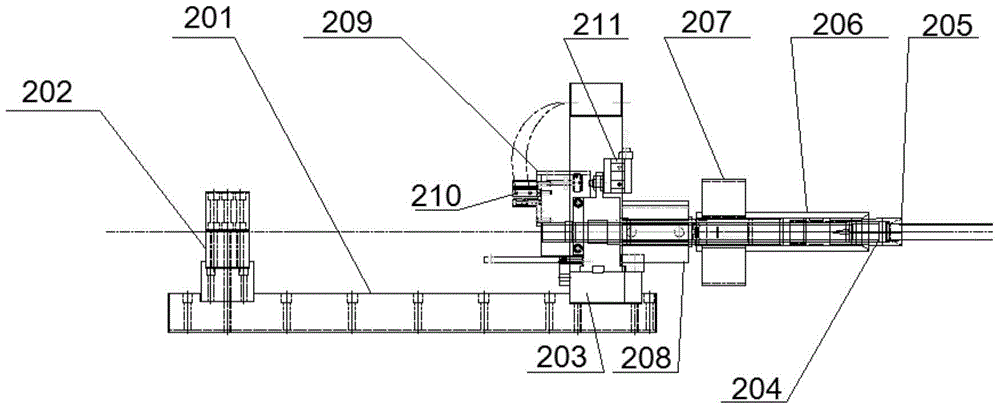

[0017] like figure 1 , 2 As shown, the pipe fixing fixture structure of the pipe expansion equipment is as follows:

[0018] The machine head installation base plate 201 is the support mechanism of the pipe material fixing fixture of the pipe expansion equipment. Other components are fixed on the machine head installation base plate 201. The upper portion is a wide-mouth structure, and is clamped by a locking mechanism. The locking mechanism includes a locking jaw 205 and a locking sleeve 206. The locking jaw 205 is in a hollow tubular shape, one end is a fixed end, and the other end is a clamping end. The clamping ends of the clamping jaws 205 are opened into multiple petals, and the inner side of each petal is provided with a hook-shaped structure for clamping a wide-mouth structure. When the clamping end of the locking jaw 205 is tightened, the multi-lobed tube wall opened at the clamping end shrinks inward, and the wide-mouth structure is clamped. When the locking sleeve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com