Roller paint device for organic composite insulator and roller paint process of organic composite insulator

A technology of composite insulators and insulators, which is applied in the direction of insulators, electrical components, circuits, etc., can solve the problems of poor adhesion between the organic insulating layer and the surface of the core, affecting the service life of the insulator, and changes in surface hydrophobicity. Novel and practical, beneficial to dust prevention and decontamination, and convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

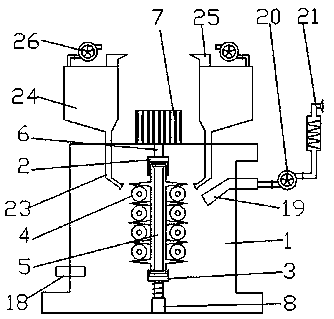

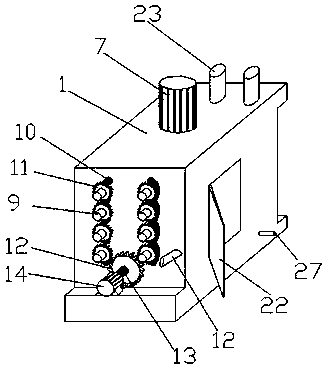

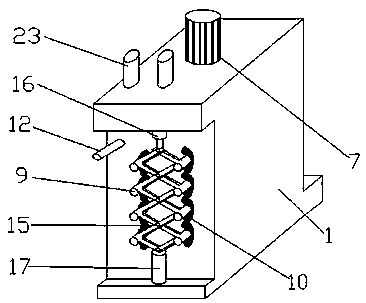

[0039] refer to Figure 1-5, a roller paint device for organic composite insulators, comprising a paint spray box 1, a rotating sleeve 2 arranged on the top wall of the paint spray box 1, a lifting sliding sleeve 3 arranged on the bottom wall of the paint spray box 1, and a paint spray The brush roller 4 on the side wall of the box body 1 is characterized in that the opening end of the rotating sleeve 2 faces downward and is sleeved with an insulator 5, and the bottom end of the insulator 5 is movably sleeved in the lifting sliding sleeve 3, so that Symmetrical brush rollers 4 are arranged between the sheds of the insulators 5; Out of the top wall of the paint spray...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com