Machining device and technological method for high-precision sheet metal part of medical equipment

A technology of medical equipment and processing equipment, which is applied in the direction of grinding drive equipment, metal processing equipment, grinding/polishing equipment, etc., and can solve problems such as troublesome handling of debris

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0032] The following is a specific implementation of the high-precision sheet metal parts processing device for medical equipment.

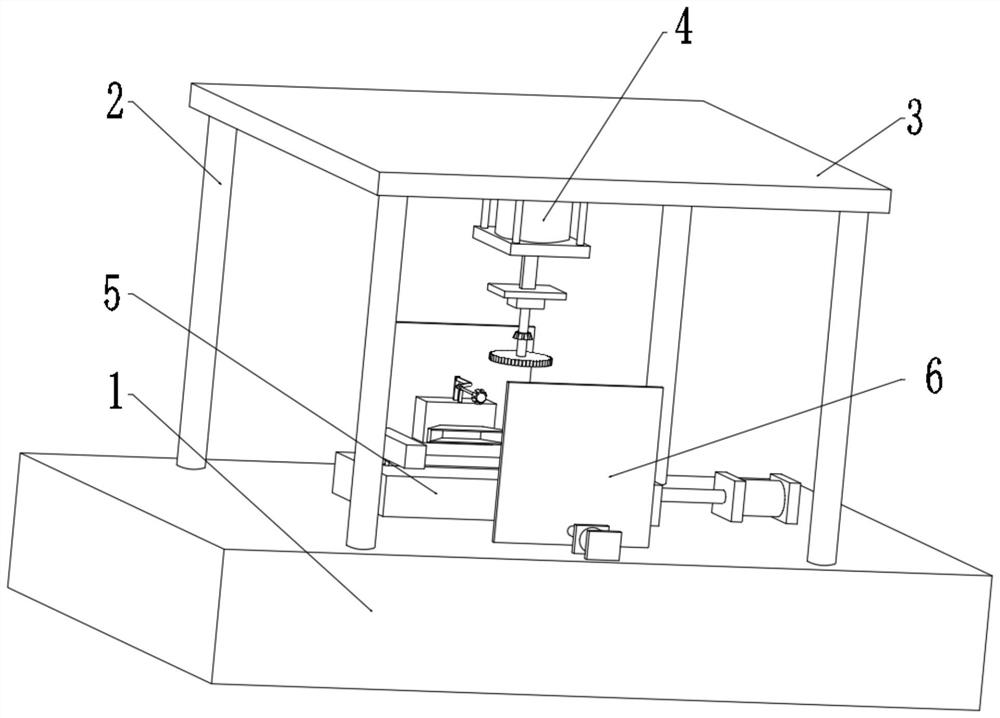

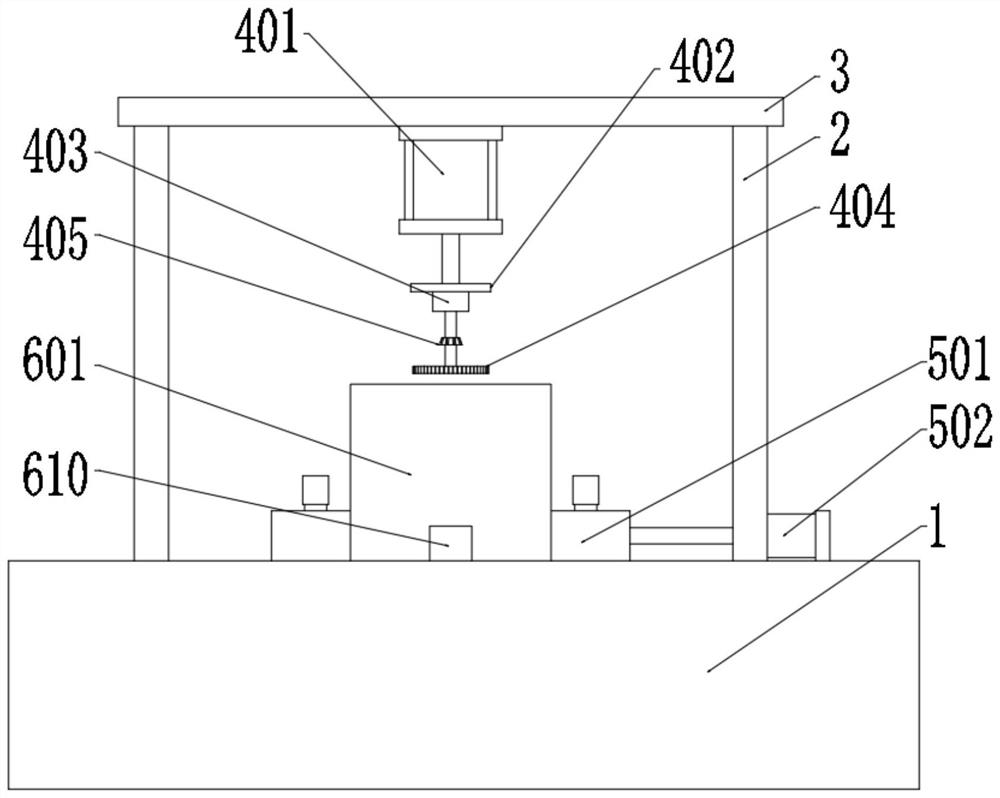

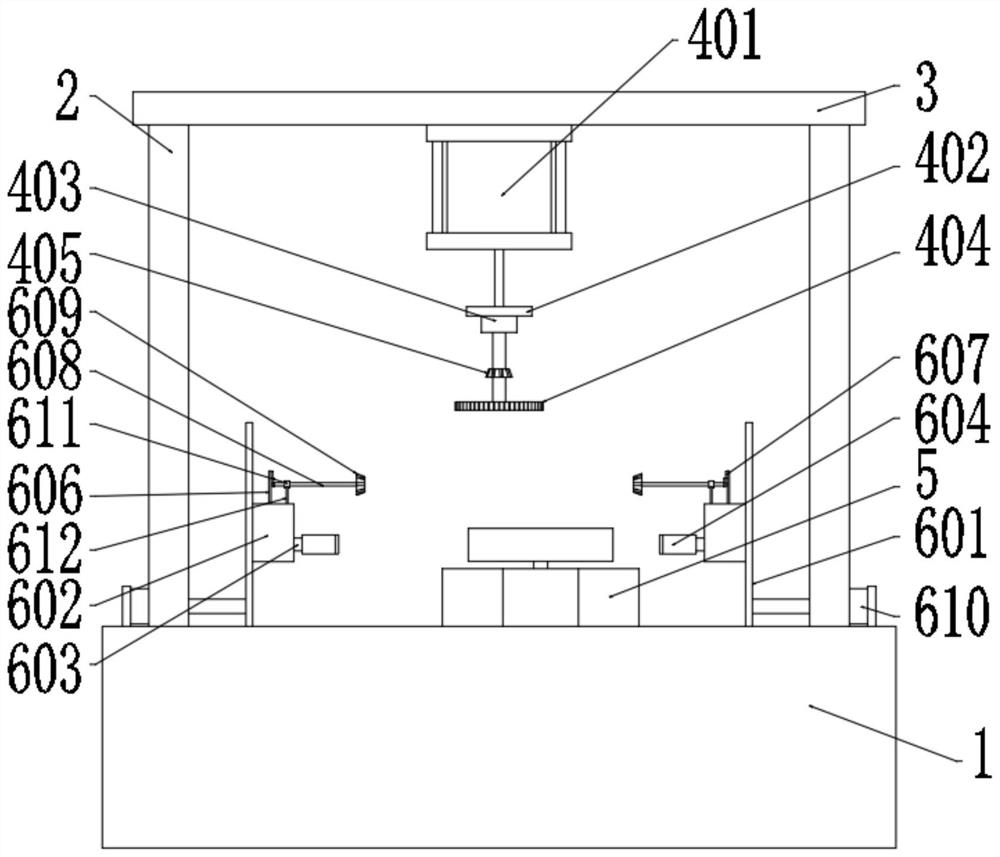

[0033] see Figure 1-6 , a high-precision sheet metal processing device for medical equipment, including a processing seat 1, a support column 2 is fixedly installed around the top of the processing seat 1, the other end of the support column 2 is fixedly connected to a top plate 3, and the bottom end of the top plate 3 is provided with a grinding As for the mechanism 4, the top end of the processing seat 1 is provided with a clamping mechanism 5, and the front and rear sides of the clamping mechanism 5 are provided with an adsorption mechanism 6.

[0034] Specifically, the grinding mechanism 4 includes a telescopic cylinder 401 fixedly connected to the top plate 3, the extended end of the telescopic cylinder 401 is fixedly connected with a connecting plate 402, the bottom end of the connecting plate 402 is fixedly equipped with a grinding motor ...

specific Embodiment approach 2

[0048] The following is a specific implementation of the processing method of the high-precision sheet metal processing device for medical equipment. The processing method of the high-precision sheet metal processing device for medical equipment includes the following steps,

[0049] Step 1. Before grinding, put the sheet metal parts to be polished between the clamping plates 503, and then start the drive motor 507 to drive the threaded shaft 506 to rotate. When the threaded shaft 506 rotates, it can drive the synchronous sleeve 505 toward the adjacent direction to move, thereby driving the clamping plate 503 to move toward the direction of the sheet metal until the sheet metal is fixed.

[0050] Step 2. When grinding, the telescopic cylinder 401 drives the connecting plate 402 to move, thereby driving the grinding wheel 404 to move to the grinding position, and then drives the adsorption seat 602 by adjusting the cylinder 610, so that the synchronous bevel gear 609 moves to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com